Optimization of Recycled PLA Filaments for Reliable 3D Printing

The revolution of rechargeable PLA filaments is transforming sustainability in 3D printing, but many users encounter significant technical obstacles that compromise the final quality. Variability in dimensions and composition generates frequent interruptions that frustrate even the most experienced users. 🌀

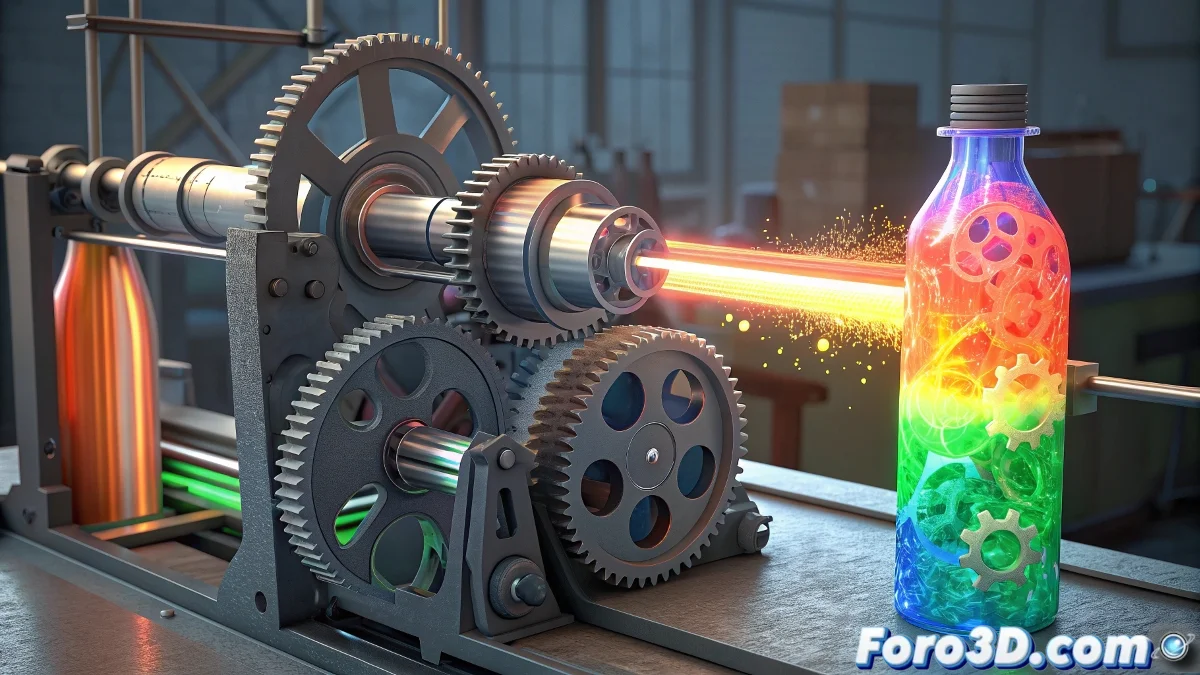

Advanced Purification of the Base Material

The initial quality of the plastic directly determines the success of the recycling process. Bottles require meticulous processing that includes intensive washing, complete removal of adhesives, and homogeneous grinding. Implementing a multi-layer filtering system with variable precision meshes eliminates contaminants that alter the rheological properties of the material during extrusion.

Optimal Preparation Process:- Washing with degreasing solution and complete drying to eliminate residual moisture

- Controlled grinding that produces uniform-sized flakes for consistent melting

- Progressive filtration with 100 and 50 micron meshes that retain problematic particles

Material purity is not a luxury, it is the fundamental basis for reliable and reproducible extrusion

Precision in Thermal and Mechanical Control

The dimensional stability of the filament critically depends on the balance between temperature, extrusion speed, and cooling. Employing high-precision calibrated sensors allows maintaining thermal ranges between 185-200°C according to the specific characteristics of each PLA batch. The integration of laser measurement systems provides instant feedback that automatically adjusts the pulling speed, compensating for variations in viscosity and flow.

Key Quality Control Elements:- Precision thermocouples strategically located in critical melting zones

- Optical diameter sensors that continuously monitor the extruded filament

- Control algorithms that synchronize temperature, speed, and cooling

Integrated Verification and Storage Systems

Continuous monitoring during winding identifies deviations before they compromise complete prints. Solutions with USB cameras and specialized software analyze every centimeter of filament, activating immediate alerts when dimensional anomalies are detected. Hermetic storage with humidity control preserves the mechanical properties of recycled PLA, preventing degradation due to environmental absorption. 🔍

Transforming plastic waste into professional printing material requires more than good intentions: it demands technical precision, appropriate equipment, and rigorous methodologies. These strategies turn an initially problematic material into a viable alternative even for applications requiring high reliability and repeatability. Who would have thought that those empty bottles could become the raw material for our most ambitious projects. 💪