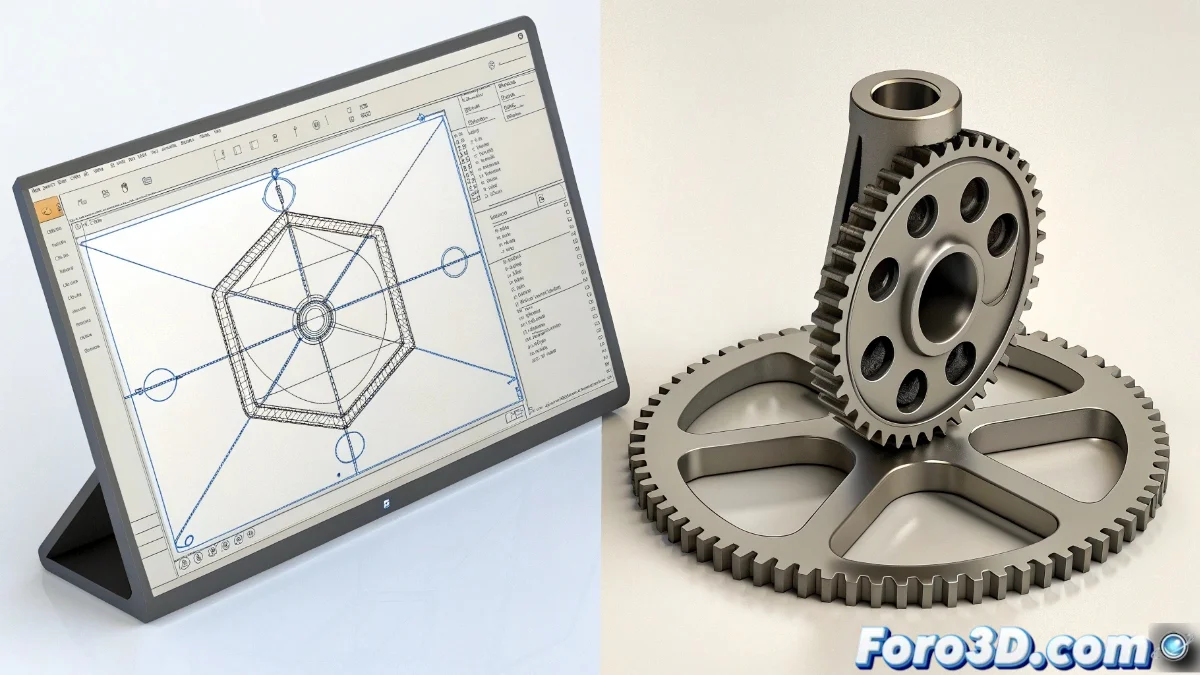

OpenSCAD vs SolidWorks: comparative analysis for parametric design

3D modeling through programming represents a revolutionary approach where OpenSCAD stands out as a free tool that uses scripts to generate exact geometries, ideal for technical projects that demand absolute dimensional control. However, when compared to professional solutions like SolidWorks or Fusion 360, substantial differences emerge in capabilities and work methodologies. While the former focuses on algorithmic precision, the latter provide complete ecosystems with sophisticated visual tools that streamline the creation of complex models 🛠️.

Strengths of the code-based parametric approach

The differential essence of OpenSCAD lies in its ability to produce exact parametric models through programming, facilitating systematic modifications without repetitive manual intervention. This methodology is particularly valuable for developments that require mathematically controlled variations or where conditional logic is determinant. Additionally, its open-source and free nature makes it an accessible alternative for users who prioritize technical precision without significant financial investment 💻.

Key advantages of OpenSCAD:- Absolute precision through mathematical definition of geometries

- Automation of variations and parametric adjustments

- Free access without license costs for any user

Programming in 3D design opens infinite possibilities for customization, but requires an algorithmic mindset compared to traditional visual approaches

Comparative disadvantages with professional environments

Despite its merits in parametric precision, OpenSCAD presents significant shortcomings in advanced graphical interface for direct geometry manipulation, slowing down creative processes compared to SolidWorks or Fusion 360. These commercial platforms integrate complete functionalities such as visual assemblies, dynamic simulations, tolerance analysis, and manufacturing tools that optimize workflows in professional environments. The absence of these features limits the applicability of OpenSCAD in projects that demand agile iteration or integration with industrial production pipelines, where visualization and assembly validation are critical ⚙️.

Main limitations:- Lack of visual tools for direct manipulation

- Absence of advanced simulation and analysis modules

- Limited integration with industrial manufacturing processes

Divergent approaches in user experience

The dichotomy between both approaches reflects fundamental preferences in the 3D design community: while some users enjoy the meticulousness of programming spheres through code, others prefer the immediacy of drag-and-drop cubes like digital Lego blocks. This divergence shows that in the universe of three-dimensional modeling, the patience to debug scripts does not always equate to the satisfaction of observing real-time simulations. The choice between these tools ultimately depends on the specific project requirements and the preferred work methodology of each designer 🎯.