Oceanco and 3D Printing in Superyacht Construction

The shipyard Oceanco, a world leader in the construction of luxury superyachts, has integrated additive manufacturing into its processes. It uses metal and polymer 3D printers to create parts that would be unfeasible with conventional methods, setting a new standard of innovation in the nautical sector. 🚤

Revolution in the Design and Manufacturing of Components

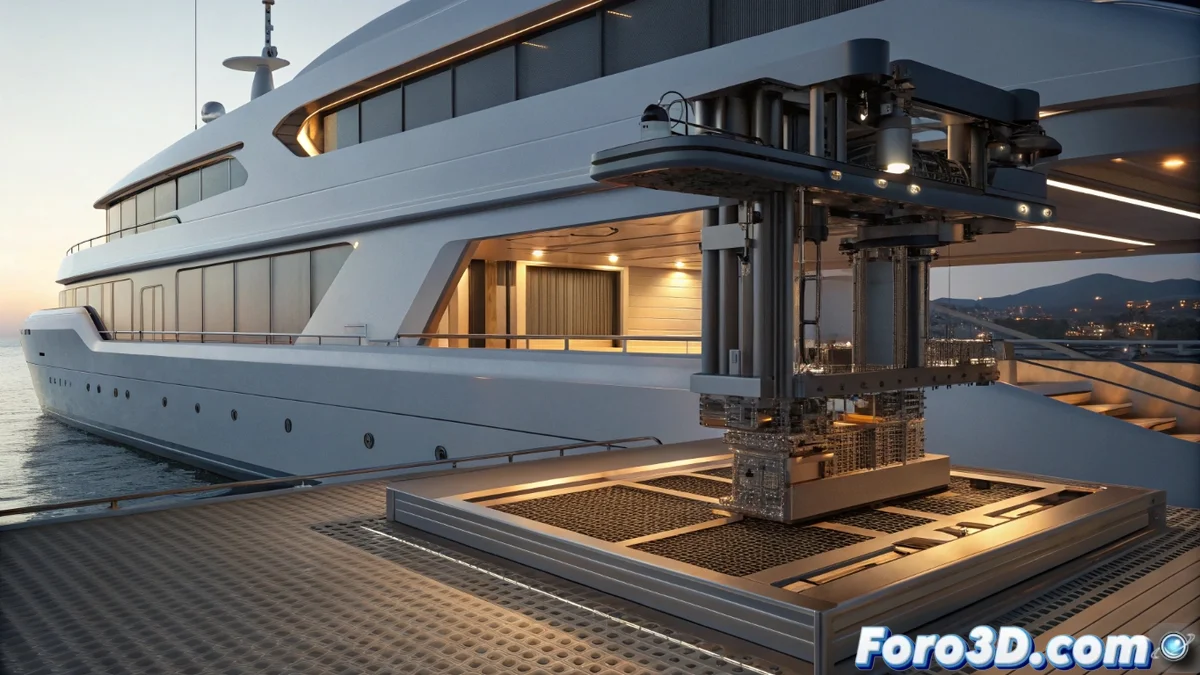

The technology is applied directly in the yacht design phase, enabling the materialization of complex geometries. Oceanco produces elements such as ornamental ventilation grilles, deck fittings, and exclusive interior components. This capability fuses art and functionality in an optimized and highly customizable production flow for each client.

Concrete applications of additive manufacturing:- Lightweight structural components: Supports and assemblies with aerodynamic and organic designs.

- Customized decorative elements: Unique pieces that reflect the specific taste of each owner.

- Rapid functional prototypes: Acceleration of the development and design validation cycle.

3D printing turns bold design concepts into tangible realities, challenging the limits of traditional shipbuilding.

Operational and Strategic Benefits

The adoption of 3D printing brings significant advantages. Oceanco achieves a notable reduction in manufacturing lead times and minimization of material waste, as only the necessary raw material is used. This positively impacts costs and reinforces the commitment to sustainability through resource reuse.

Key advantages of the method:- Production efficiency: Shorter time from design to the final installed part.

- Cost reduction: Especially relevant for short runs or highly complex unique parts.

- Greater design freedom: Possibility to create internal and external shapes that were impossible to mill or cast.

The Future of Customization at Sea

In the exclusive world of superyachts, where luxury is defined by unique details, 3D printing is consolidating as a fundamental tool. It allows shipyards like Oceanco to maintain their standard of excellence while exploring new horizons of innovation and customization. The technology envisions a future where distinction lies not only in precious materials, but in the complexity and exclusivity of achievable forms. ⚓