The Engineering Material for 3D Printing

Nylon, technically known as Polyamide or PA, represents the engineering materials category in the world of 3D printing. This thermoplastic has been proving its worth in industrial applications for decades and is now available to creators and designers. Its unique combination of strength, durability, and versatility makes it the preferred choice for parts that must withstand demanding continuous use conditions.

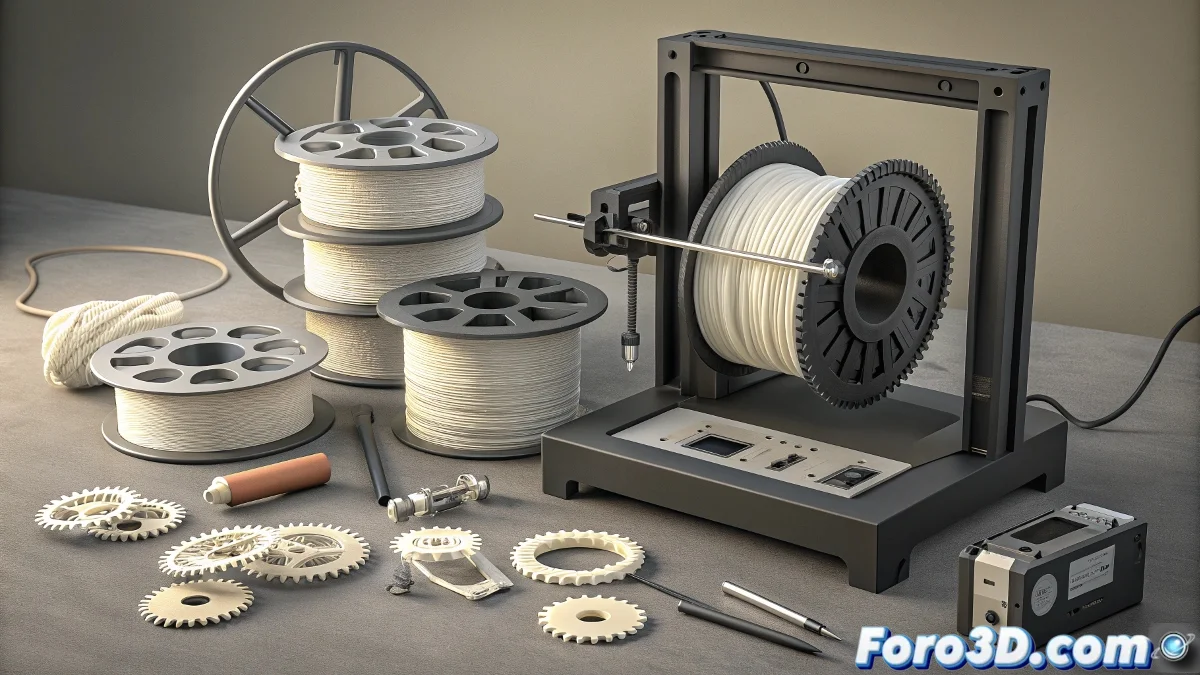

What truly defines Nylon is its exceptional fatigue and wear resistance. Unlike more basic materials like PLA, Nylon can flex repeatedly without breaking, recovering its original shape once the stress ceases. This property, combined with its low surface friction, makes it ideal for gears, joints, and mechanical components that require movement and long-term durability.

Exceptional Technical Properties of Nylon

- Superior impact resistance and toughness compared to most filaments

- Low coefficient of friction that makes it ideal for moving parts

- Chemical resistance to oils, greases, and many solvents

- Ability to absorb moisture from the environment that affects its printing

The Challenge of Hygroscopicity

The main difficulty when working with Nylon lies in its tendency to avidly absorb ambient moisture. This material can become unprintable in a matter of hours if exposed to air without protection, developing bubbles, strings, and poor finishes during printing. Experienced users store the filament in airtight containers with desiccants and usually dry it in a specialized oven before each use to ensure optimal results.

Nylon rewards meticulous storage with exceptional mechanical performance

Printing with Nylon requires high temperatures and precise environmental control. The hotend must reach between 240°C and 260°C, while the heated bed needs to be maintained between 70°C and 90°C. Many professionals recommend the use of enclosed chambers to maintain a stable ambient temperature and avoid abrupt cooling that can cause delamination. Bed adhesion is usually achieved with PEG or special glue for Nylon.

Applications Where Nylon is Indispensable

- Gears and mechanisms that require wear resistance

- High-performance automotive and aerospace components

- Custom tools and production fixtures

- Parts subjected to repeated impacts and dynamic stresses

Different Nylon variants, such as PA6, PA66, or PA12, offer specific nuances in mechanical properties and printing temperature. Each finds its particular niche in technical applications where performance takes precedence over ease of use. For projects that demand the utmost in durability and functionality, Nylon remains the undisputed reference among professional 3D printing materials. ⚙️

Mastering Nylon is like taming a wild bull: it requires patience, proper equipment, and respect for its particularities, but the performance reward is worth every effort. 🐂

You can see this product and similar ones in the : store