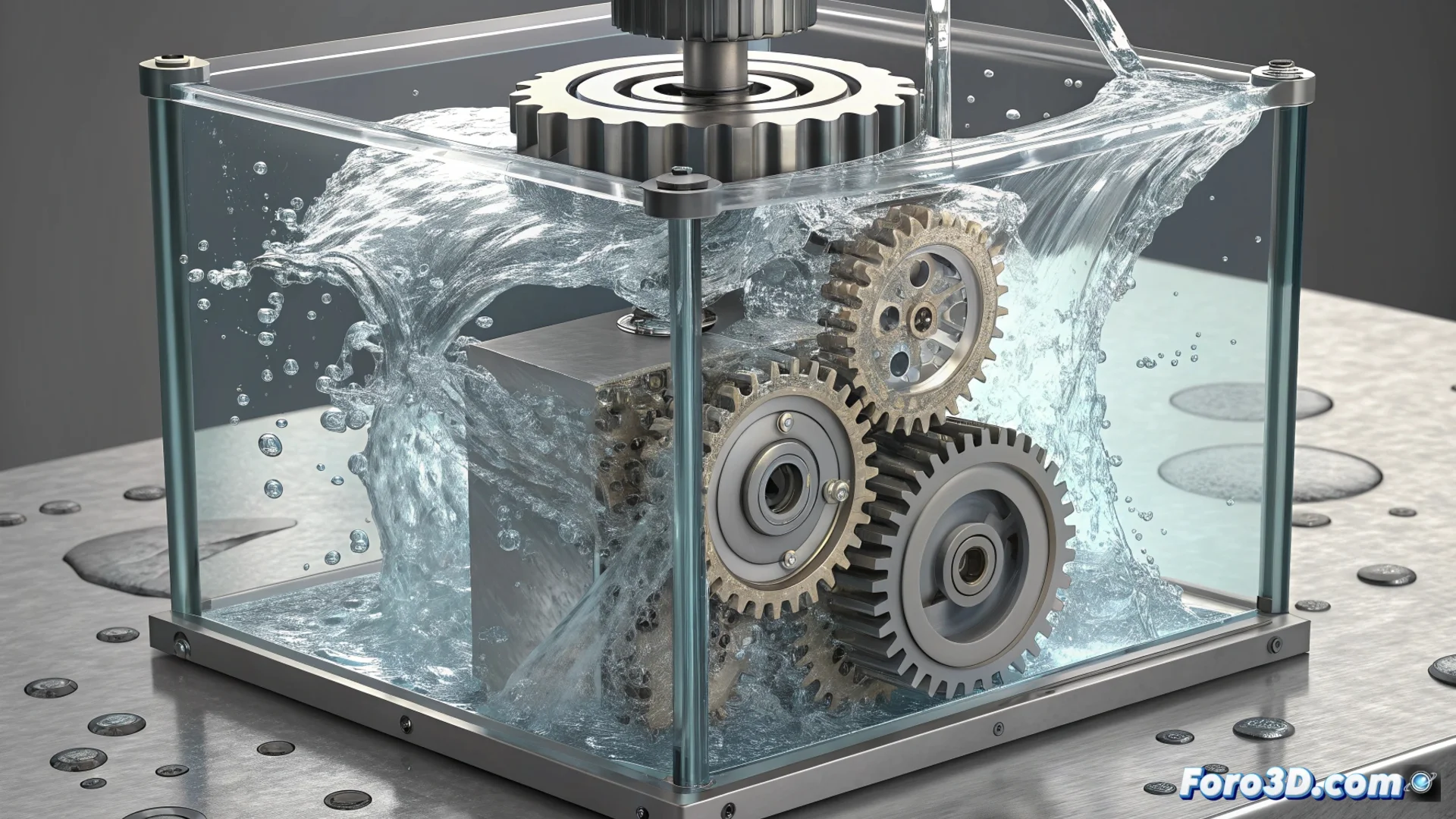

New York University develops gears that run on water

A group of researchers has created a revolutionary concept for transferring motion without using solid parts that touch. Their system uses water as the main element, which could change how we design durable machines. 🚰

A principle that avoids wear

The mechanism is based on hydrodynamics principles. Instead of gear teeth, it uses fluid-filled chambers that expand and contract in a controlled manner. Pumping water from one chamber to another generates continuous rotary motion in a shaft, without any solid component rubbing against another. This eliminates the core problems of traditional systems: friction and progressive wear.

Key advantages of the fluidic system:- It does not require lubricants and needs very little maintenance to keep it operational.

- It operates more quietly than metal gears.

- It can operate in environments with dust or abrasive particles that usually damage conventional mechanisms.

Perhaps the greatest achievement is creating a machine that, literally, does not have a single loose gear.

Where this technology could be implemented

The potential applications are diverse and leverage the system's reliability and biocompatibility. By not relying on metal contacts, it opens the door to uses in very specific and demanding conditions.

Fields of application under study:- Implantable medical devices, where failure due to wear is not an option.

- Soft robotics, which requires smooth and adaptable movements.

- Industrial machinery that must operate in extreme conditions of dirt or corrosion.

The challenge for the future

The main challenge for researchers now is to optimize efficiency and power transfer of the system. To compete with established mechanical mechanisms, it must demonstrate that it can offer similar or superior performance. The advance represents a paradigm shift in transmission design, prioritizing longevity and smoothness over the complexity of parts. ⚙️