The Digital Oracle of 3D Printing

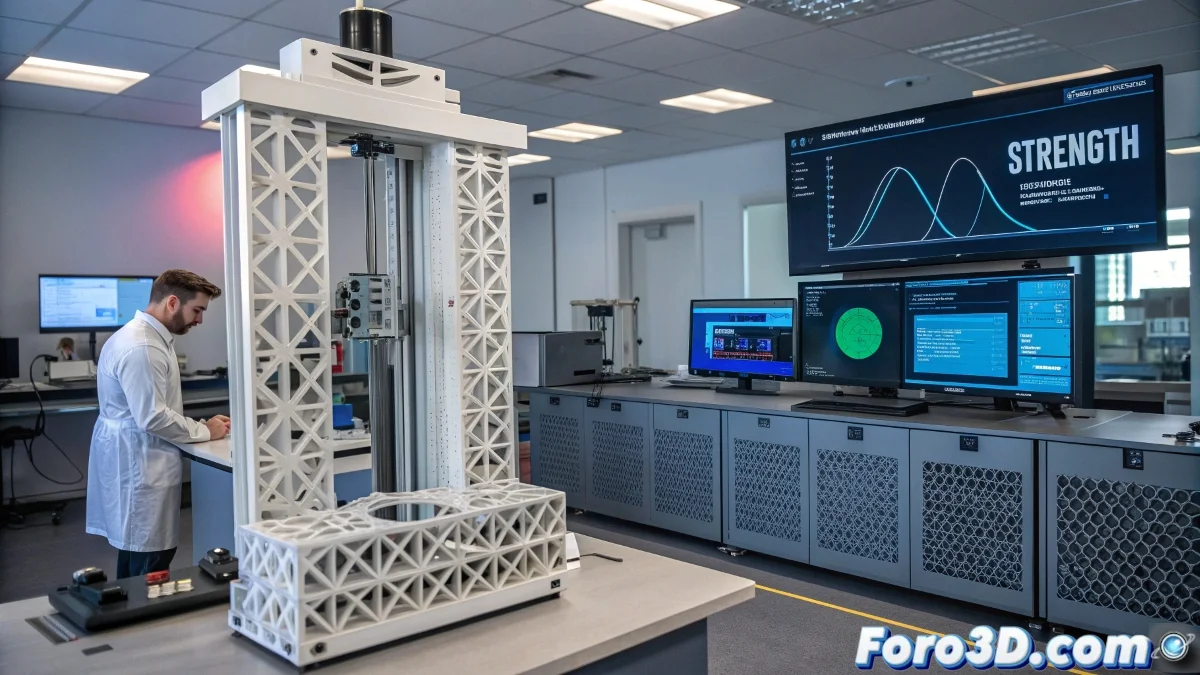

The University of Maine has developed what could be called the "structural fortune teller" for 3D printed parts 🔮🖨️. Its new system predicts with accuracy how lightweight materials will behave, saving engineers from those "oops, it shouldn't have broken" moments we all dread.

Quantum Physics Meets 3D Printing

Combining advanced computational modeling with destructive lab tests (poor test pieces 💥), the team has created a system that anticipates weak points before printing. Now you can know if your design will fly or shatter... without having to build it first.

It's like having a crystal ball for engineers. We can see potential fractures before they happen, saving time, money, and more than a few headaches — explains the lead researcher, probably surrounded by broken parts that served as lessons.

Why This Changes the Game

- Certified Safety: Ideal for critical components in aviation and automotive

- Optimized Design: Less material, same strength = more efficiency

- Rapid Prototyping: Validates designs in hours, not months

- Sustainability: Reduces waste of expensive materials

The applications are endless: from lighter drones to spacecraft components. And the best part: you no longer need to cross your fingers when testing your designs (though some superstitious ritual always helps) ✨.

So engineers of the world: your days of guessing strengths are over. The future of professional 3D printing is predictable... though the coffees they'll need to interpret the data remain inevitable ☕📊.