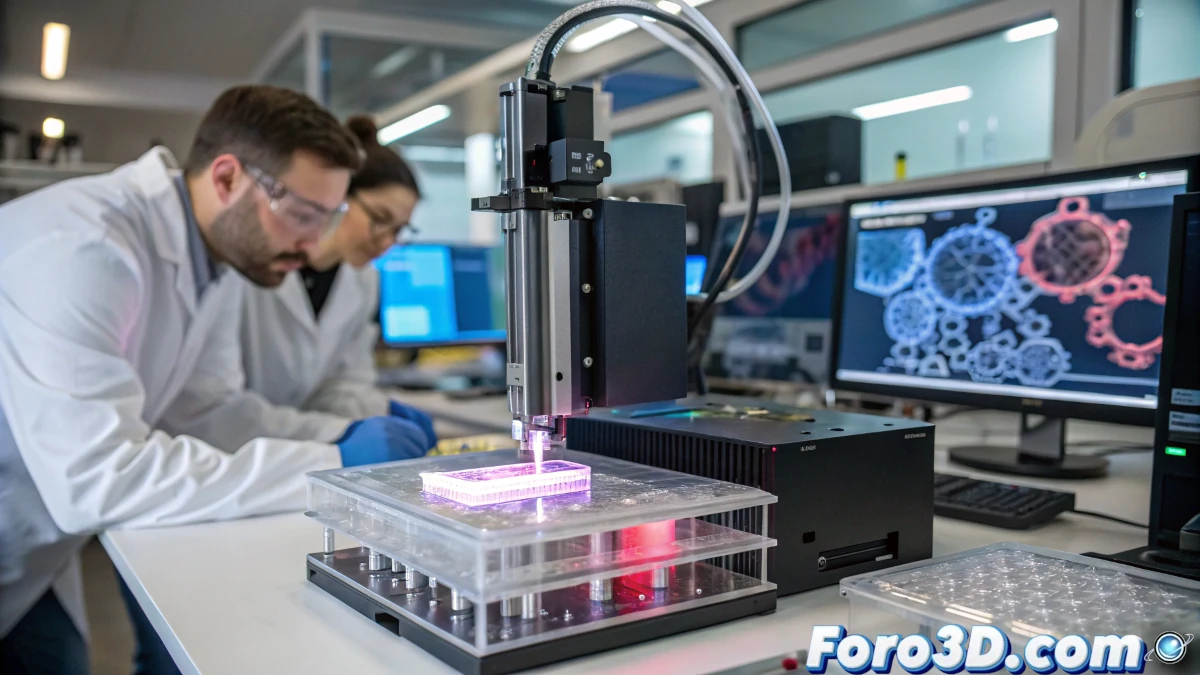

A New Method Revolutionizes the Manufacturing of Microfluidic Devices

In the world of technology and research, advances in manufacturing can completely change the way devices are developed and used. Recently, researchers from Purdue University have developed an innovative method to create microfluidic devices using vat photopolymerization (VPP). This process, which is patent-pending, allows for the fabrication of transparent devices with incredibly small channels, just 100 microns wide and 10 microns deep, which could revolutionize the production of these devices and make them more accessible.

LCD Technology and Ultraviolet Light as the Foundation

The Purdue team has utilized liquid crystal display (LCD) technology combined with ultraviolet light to solidify photopolymers, offering an alternative to traditional manufacturing methods. This approach not only eliminates the need for expensive equipment and cleanroom environments but also enables the creation of much narrower channels than those achieved with conventional 3D printing techniques, such as fused filament fabrication.

"This method democratizes the production of microfluidic devices, making them more accessible and cost-effective." — Purdue Research Team.

Overcoming the Limitations of Traditional Methods

Current methods for producing microfluidic devices face several limitations. Traditional manufacturing requires multiple steps and specialized facilities, while conventional 3D printing techniques struggle to create channels narrower than 500 microns. The new VPP method not only overcomes these restrictions but also maintains high resolution and transparency, making it ideal for applications requiring extreme precision.

- Superior Resolution: Channels up to 100 microns wide.

- Transparency: Ideal for applications requiring visibility.

- Cost Reduction: Eliminates the need for cleanrooms and expensive equipment.

Applications in Single-Cell Analysis

The research team, led by assistant professor Huachao Mao, has successfully demonstrated the capabilities of this technology in single-cell analysis applications. They have created channels capable of forming single lines of cancer cells and developed complex networks that mimic capillary connections. These advances could have a significant impact on biomedical research, enabling more detailed and precise studies.

Potential in Multiple Fields

This innovation has potential applications in various fields, such as biomedical research, environmental testing, geology, and manufacturing. Microfluidic devices can analyze small volumes of material on the microliter or nanoliter scale, allowing for rapid and precise diagnostic tests. Additionally, their ability to mimic complex biological structures opens new possibilities in disease studies and treatment development.

The Future Combines 3D Printing and 2D Nanofabrication

The research team is currently working on combining 3D-printed microfluidic devices with conventional 2D nanofabrication methods. This project, supported by the School of Engineering Technology, aims to leverage the advantages of both technologies to create even more advanced and versatile devices. With this approach, new doors are expected to open in research and industry, taking microfluidic device manufacturing to a completely new level.

This advance not only represents an important step in manufacturing technology but also has the potential to transform multiple industries, making microfluidic devices more accessible and efficient than ever before.