New Continuous Fiber Composite Filament for FDM 3D Printing

An international consortium formed by the Institute of Space Technology in Islamabad, the National University of Science and Technology, and Ajman University has revolutionized the field of additive manufacturing through the development of an innovative procedure to produce continuous fiber-reinforced polymer composite filament, specifically optimized for FDM 3D printing technology 🚀.

Advances in Mechanical Properties

The patented system integrates continuous E-glass fibers within a PLA matrix, ensuring precise fiber alignment and complete polymer encapsulation during extrusion. This results in a filament with exceptionally enhanced mechanical properties that far surpass those of conventional PLA.

Test Results:- Average tensile strength of 146.75 megapascals, compared to 60 MPa of pure PLA

- Young's modulus of 4.95 gigapascals, compared to 3.68 GPa of the base material

- Fiber volume of 2.8% in a standard 1.75 mm diameter filament

These figures represent substantial improvements of approximately 2.4 times in strength and 1.35 times in stiffness, coming remarkably close to the values predicted by theoretical models.

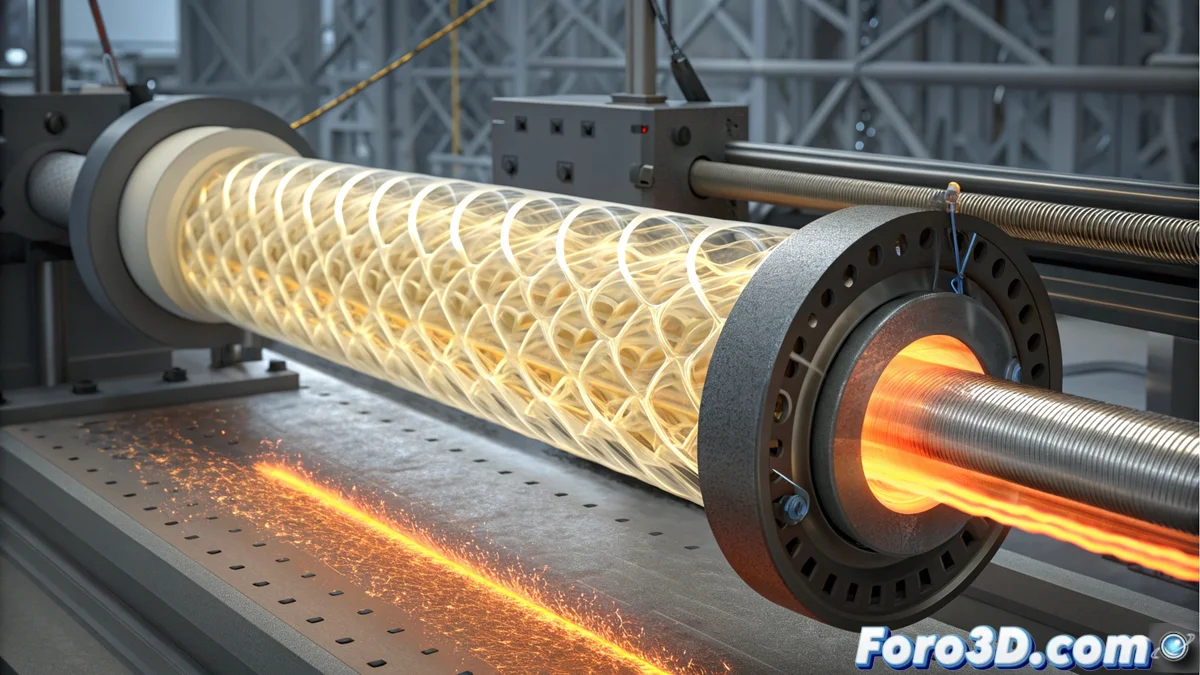

Technical Characterization and Manufacturing Process

Analyses using electron microscopy and spectroscopy confirm uniform polymer impregnation, excellent fiber coating, and minimal presence of voids in the composite material structure. Additional thermal characterization indicates that this composite exhibits degradation onset at higher temperatures than conventional PLA, suggesting greater overall thermal stability 🔥.

Required Specialized Equipment:- Winding units for precise handling of continuous fibers

- Extrusion system with advanced temperature control

- Thermal chamber for post-extrusion treatment

- Draw spool with speed synchronization

Industrial Applications and Future Prospects

This technological advancement opens new possibilities for manufacturing lightweight yet high-strength structural components in demanding sectors such as aerospace, automotive, and industrial, where the combination of weight reduction and maintenance of mechanical properties is crucial ⚙️. The main current challenge lies in adapting domestic 3D printers to handle this composite material without compromising print quality or structural integrity during the manufacturing process.