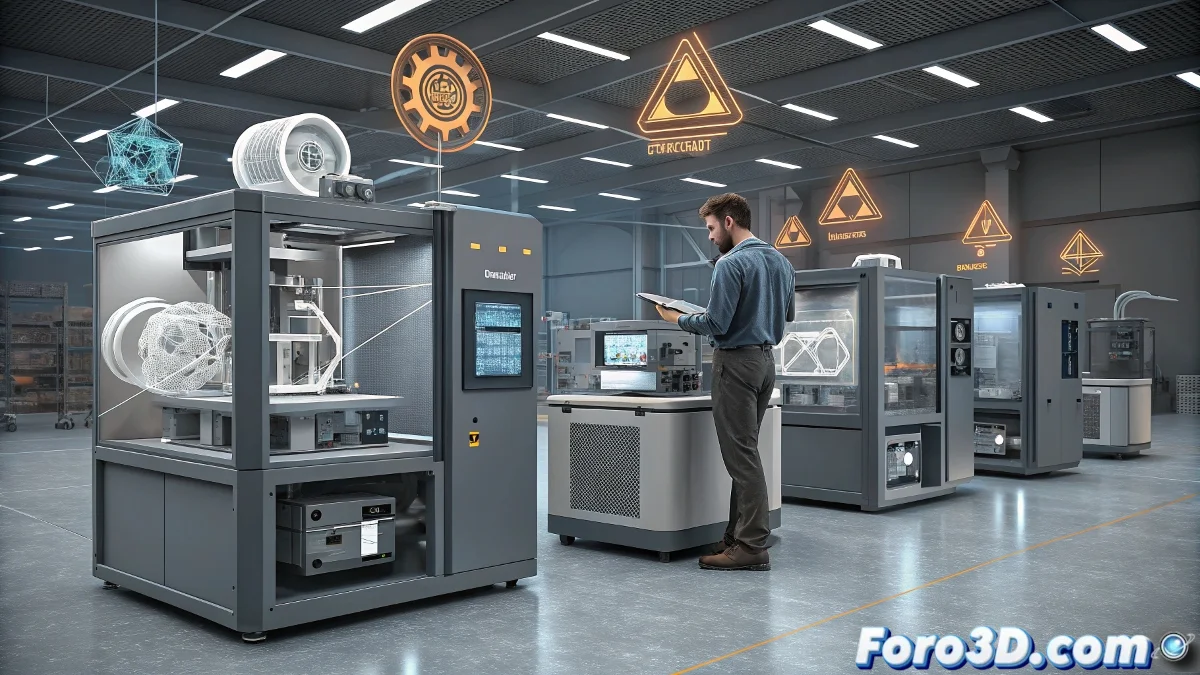

When 3D Printing Meets Industrial Standards

ASTM International has taken a crucial step for the maturation of additive manufacturing by approving a new comprehensive standard that standardizes processes, quality, and interoperability in 3D printing. 🏭🔧 This initiative seeks to transform additive manufacturing from experimental technology to a reliable industrial process, particularly in critical sectors like aerospace, medical, and automotive where consistency and traceability are non-negotiable.

Scope and Components of the New Standard

The standard establishes a complete framework that covers the entire additive manufacturing lifecycle. 📋 It includes detailed guidelines for file preparation, printing parameters, quality control, and post-processing, creating a common language for manufacturers, suppliers, and end users. The documentation protocols ensure that every printed part has complete records of materials, parameters, and environmental conditions—critical for regulated applications.

This standardization represents the culmination of years of research and industrial collaboration, marking the point where additive manufacturing leaves digital craftsmanship to become true modern manufacturing.

Impact on Quality Control and Reproducibility

The standard addresses one of the biggest challenges of 3D printing: variability between machines, materials, and operators. 📊 It establishes dimensional tolerances, inspection standards, and verification protocols that enable consistent reproducibility across different facilities and technologies. This is particularly important for critical parts where a defect could have catastrophic consequences.

Benefits of Interoperability and Collaboration

- Multi-platform compatibility: Guidelines for files and parameters to work on equipment from different manufacturers.

- Cost reduction: Less need for re-qualification when switching between technologies or materials.

- Accelerated innovation: Common framework that facilitates collaboration between industry, academia, and regulators.

- Simplified certification: Standardized processes for regulatory approval in medical and aerospace sectors.

Implications for the Supply Chain

Standardization allows additive manufacturing to be integrated into global supply chains with confidence. 🌐 Manufacturers can now produce parts in multiple locations with guaranteed consistency, reducing dependence on individual specialized centers. Complete traceability also facilitates recall management and failure analysis when necessary.

Future of Additive Manufacturing

This standard lays the foundation for the next phase of 3D printing adoption—mass production of end components instead of just prototypes. 🚀 By providing the framework for consistent quality, it opens the door to applications previously considered too risky for additive manufacturing.

Thus, while our home 3D printers will occasionally still make plastic spaghetti, the industry now has standards to prevent that from happening in critical applications… because in the additive manufacturing of the future, the only thing that should be flexible is the design, not the quality. 😉