New Aluminum Alloys Withstand High Temperatures Thanks to 3D Printing

Researchers in Japan are developing aluminum alloys capable of withstanding extreme thermal conditions. This breakthrough is possible thanks to metal additive manufacturing, a technology that builds components with intricate shapes layer by layer, overcoming the limitations of conventional casting methods. 🚀

The Technique That Redefines How Metal Is Built

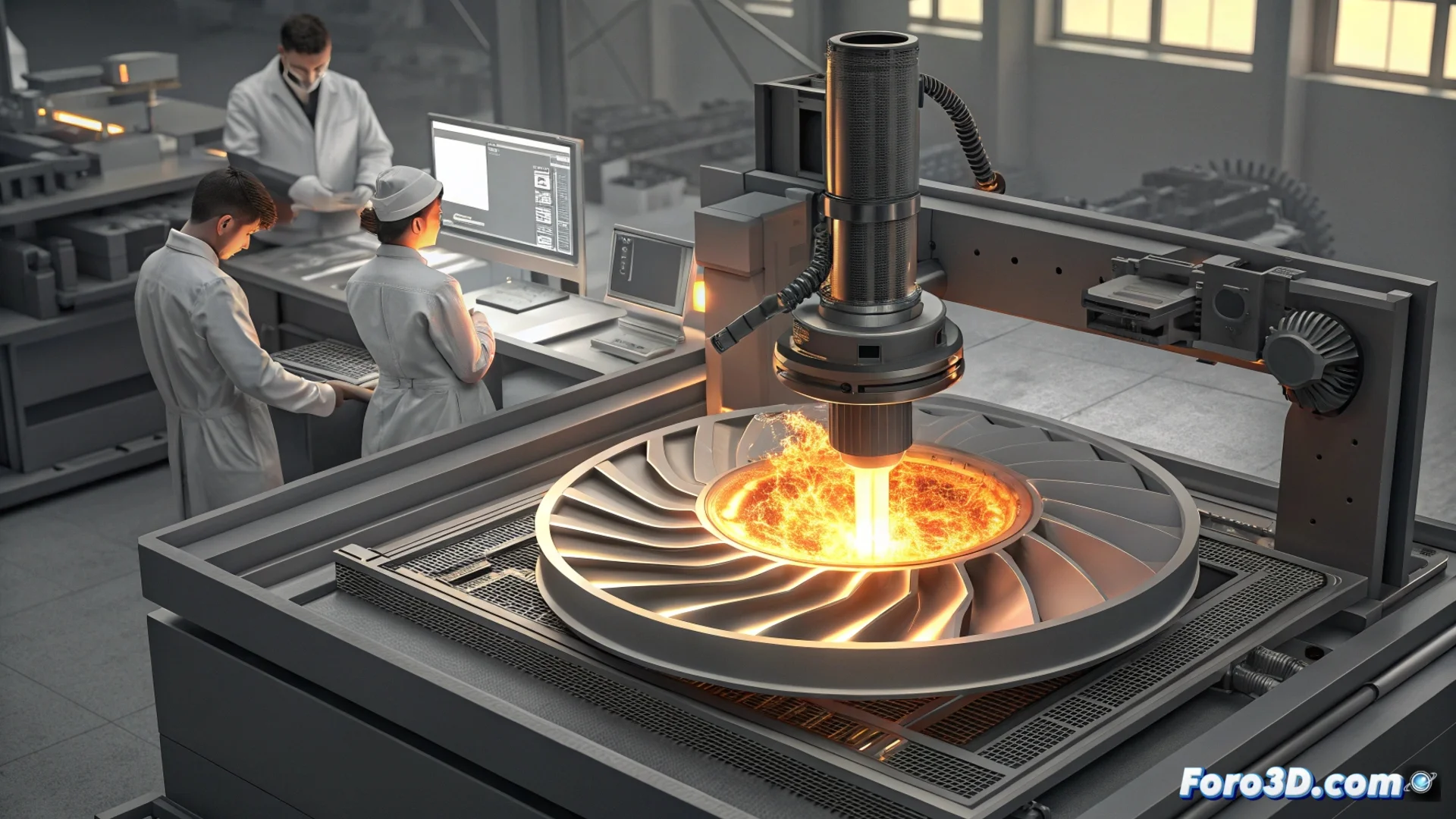

The metal 3D printing process works by fusing thin layers of metal powder using a laser or electron beam. This approach enables the production of parts that would be impossible or very costly to make with subtractive techniques. The main goal is to obtain lightweight materials that maintain their integrity under intense heat, a fundamental requirement for components in turbines and jet engines.

Key Advantages of Additive Manufacturing:- Allows the creation of complex geometries without the need for molds or special tools.

- Significantly reduces material waste compared to traditional machining.

- Shortens the time required to produce prototypes and short runs of parts.

Science ensures that airplanes don't behave like ice cream in the sun. A small but crucial detail for safe flying.

Designing Strength from the Inside

The true innovation lies in the control over the internal microstructure of the material during the building process. Scientists can precisely distribute reinforcing nanoparticles within the aluminum matrix. These particles act by strengthening the metal's crystal lattice, preventing it from softening when exposed to high temperatures. Achieving this level of detailed control is very difficult with classical melting and forging methods.

Results of Microstructural Control:- Achieves aluminum that retains its mechanical strength above 300 °C.

- Optimizes the weight-to-strength ratio, creating lighter and more powerful materials.

- Opens doors to custom-designing materials according to the specific needs of each application.

Impact on High-Performance Industries

These developments are directly aimed at sectors that require lightweight materials with high heat tolerance. In the aerospace industry, parts for gas turbines or structural components located near engines can be manufactured. In the automotive sector, these alloys are ideal for high-performance engine parts or exhaust systems. 3D printing not only allows the creation of these parts but does so more efficiently, with less waste and in shorter timeframes. 🔧✈️