An Alloy Arriving to Lighten the Future

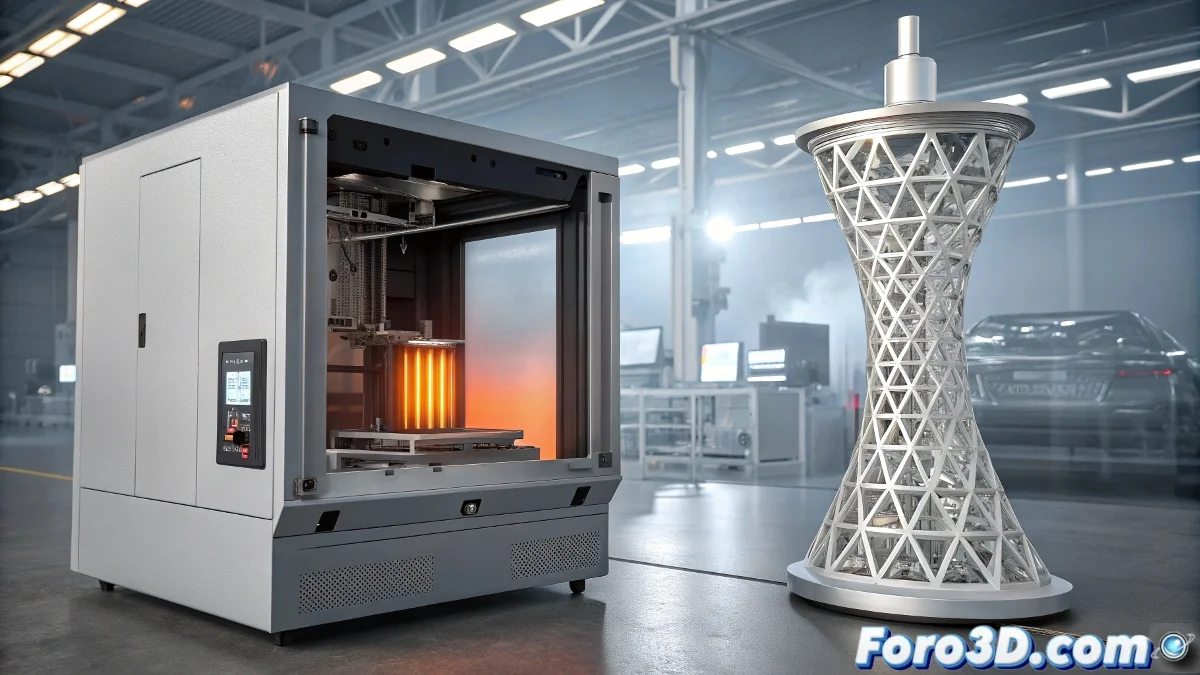

The additive manufacturing industry is celebrating the development of an aluminum alloy specifically designed for 3D printing. This material combines the best of two worlds: the characteristic lightness of aluminum with a mechanical strength that surprises even the most skeptical. 🚀 The most notable feature is its printability, which overcomes the traditional problems of metallic alloys in additive manufacturing environments. Researchers have achieved a perfect balance between mechanical properties and processability, opening up a range of possibilities in sectors where every gram counts.

Why is this alloy different?

While many existing alloys adapt with difficulty to 3D printing, this one has been conceived from scratch for this purpose. Its specific chemical composition avoids common defects such as porosity or cracks during the solidification process. The result is a material that maintains its mechanical properties even in the most challenging print orientations. 💪 Additionally, it offers an excellent strength-to-weight ratio that makes it ideal for applications where energy efficiency is crucial.

Applications that will spark the imagination

In the automotive sector, it will enable the creation of lighter structural components without compromising safety. Imagine frames, engine mounts, or suspension elements that weigh half as much but resist the same or more. In aeronautics, the possibilities are even more exciting: turbine components, structural brackets, and aircraft interior parts that withstand extreme conditions while significantly reducing fuel consumption. ✈️

Main advantages of this innovation:- Weight reduction of up to 40% in some components

- Geometric freedom for previously impossible designs

- Consolidation of multiple parts into a single unit

- Topological optimization for maximum structural performance

Not everything is perfect: challenges to overcome

Like any technological novelty, this alloy faces some obstacles. The initial development and certification costs are considerable, especially in highly regulated industries like aerospace. Additionally, it is necessary to validate its long-term behavior against fatigue and in extreme environmental conditions. Testing and qualification protocols will take time, but the first results are promising. 🔍

Current limitations:- High initial investment in development and certification

- Need to validate durability in real environments

- Adaptation of existing post-processing processes

Additive manufacturing with metals is advancing toward increasingly critical applications, and this alloy represents a significant step in that direction

The future is printed in 3D

This aluminum alloy is not just another material on the market: it represents a paradigm shift in how we conceive the design and manufacturing of technical components. By eliminating many limitations of traditional processes, it allows engineers to think of solutions that previously existed only in theory. Topological optimization and part consolidation reduce complex assemblies to single, more efficient and reliable components. 🏭

Conclusion: revolution or evolution?

More than an instant revolution, this alloy marks the natural evolution of additive manufacturing toward high value-added applications. Its impact will be felt gradually, first in non-critical components and progressively in main structural elements. The automotive and aerospace industries have before them a powerful tool to achieve their sustainability and efficiency goals. Who would have thought that aluminum, a material known for centuries, still had so many surprises to offer. 😄 After all, in the world of design and manufacturing, sometimes you have to subtract weight to add value.