Researchers have developed an innovative 3D printing technique capable of manufacturing microfibers as thin as 1.5 microns in diameter. This breakthrough, recently published in Nature Communications, overcomes previous limitations in printing ultrafine and flexible materials, enabling the creation of more precise and resilient structures.

Embedded Printing Method: A Solution for Delicate Structures

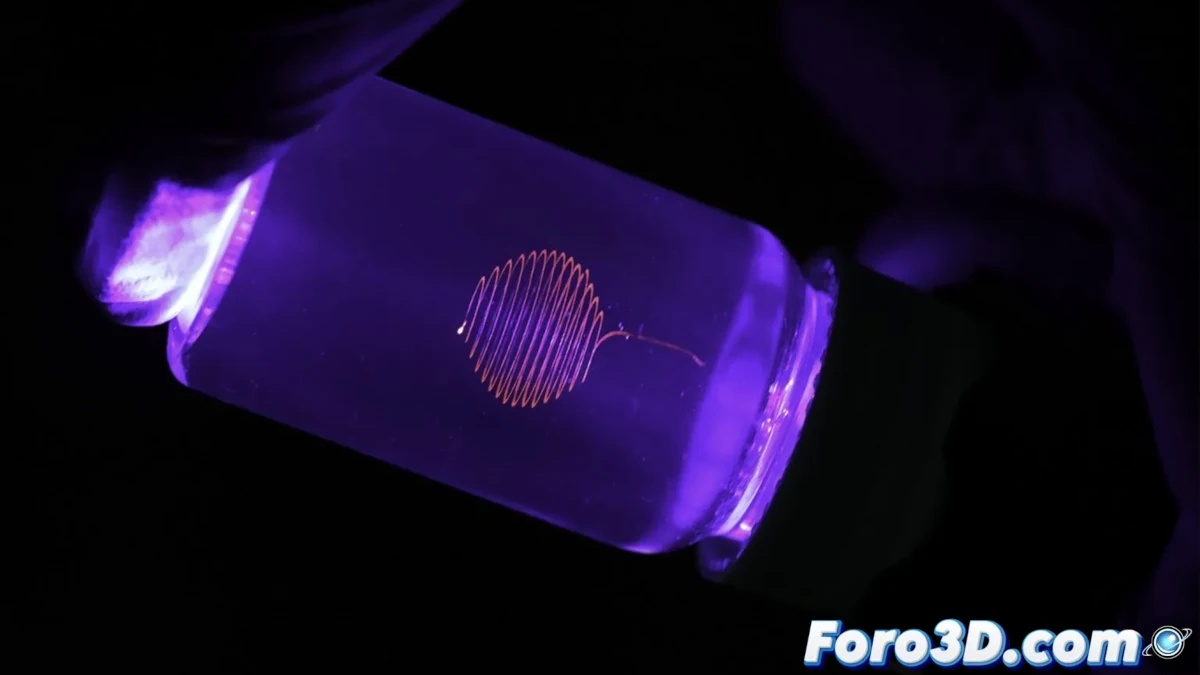

To achieve this precision, the team used a technique called embedded printing, in which the material is deposited inside a gel mold instead of building layers from the base. This approach provides additional support during printing, preventing deformations or breaks in the finest structures.

Gel and Ink Modification for Greater Stability

One of the challenges in printing microfibers is preventing them from breaking during production. To address this, the researchers modified both the gel and the ink so that the material cures instantly, providing immediate stability and improving printing precision.

Inspiration from Nature: The Secret of Ultrafine Fibers

The scientists drew inspiration from hagfish slime, a natural substance containing extremely fine fibers. By applying their printing method, they successfully replicated similar structures in 3D, maintaining their shape without being affected by gravity.

"Nature has developed astonishing solutions for creating ultrafine fibers. Our method imitates these processes to enhance 3D printing to unprecedented levels."

New Possibilities for 3D Printing of Capillary Structures

Thanks to this technology, it is possible to manufacture three-dimensional capillary structures with precise control over their diameter and arrangement. According to the researchers, this method will enable the production of ultrafine filaments for applications in:

- Biomedicine: Creation of implants and synthetic tissues.

- Advanced Textiles: Production of stronger and lighter fibers.

- Microelectronics: Development of ultrafine sensors and high-precision devices.

A Promising Future for Printing Ultrafine Materials

The development of this new 3D printing technique represents a significant advancement in the manufacturing of ultrafine materials. By imitating natural microfibers, it opens new possibilities in multiple industries, from the creation of synthetic tissues to applications in sensors and high-precision electronic devices.