Nano Dimension Revolutionizes Additive Manufacturing with ATARU

The company Nano Dimension has made a significant leap in electronic additive manufacturing with the launch of ATARU, an advanced material that transforms printing capabilities without requiring investments in new printers. This development allows users to upgrade their existing equipment through simple software updates and material kits, maximizing return on investment and offering immediate improvements in performance and functionality. 🚀

Innovative Technical Features of ATARU

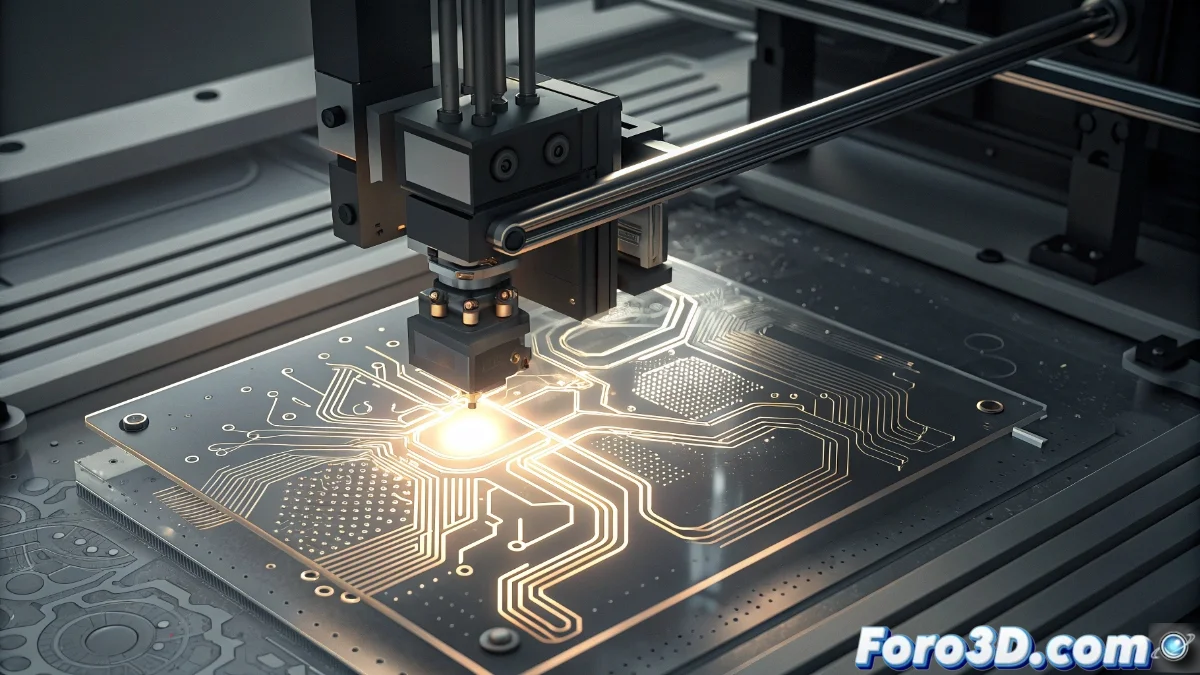

ATARU stands out for its optimized dielectric and conductive properties, specifically designed for high-frequency and microwave applications. This material enables the creation of structures with higher interconnection density and better electrical insulation, overcoming the limitations of conventional materials. Its advanced formulation allows the printing of complex electronic components with submillimeter precision, maintaining full compatibility with already installed DragonFly printers. 💡

Main Advantages of ATARU:- Optimized dielectric and conductive properties for high frequency

- Higher interconnection density and better electrical insulation

- Full compatibility with existing DragonFly printers

ATARU represents a crucial advancement by allowing current systems to reach new levels of performance without costly hardware upgrades.

Impact on the Electronics Industry

The introduction of ATARU accelerates prototype development and reduces production times in sectors such as telecommunications, aerospace, and medical devices. Engineers can iterate designs more quickly, testing configurations that were previously technically unfeasible. This flexibility drives innovation in areas where miniaturization and electromagnetic performance are critical, positioning 3D electronics printing as a viable alternative to traditional methods. 🔧

Key Applications in Various Industries:- Telecommunications: high-frequency and microwave components

- Aerospace: lightweight and high-performance prototypes

- Medical Devices: complex circuits with submillimeter precision

Future of Electronic Additive Manufacturing

With ATARU, it is finally possible to print circuits that survive multiple prototype iterations without becoming expensive and non-functional parts. This advancement not only optimizes existing resources but also democratizes access to cutting-edge technologies, enabling more companies to innovate in printed electronics. The ability to improve systems without replacing hardware underscores Nano Dimension's commitment to sustainability and efficiency in digital manufacturing. 🌟