Nagoya University Develops Heat-Resistant Aluminum Alloys Using 3D Printing

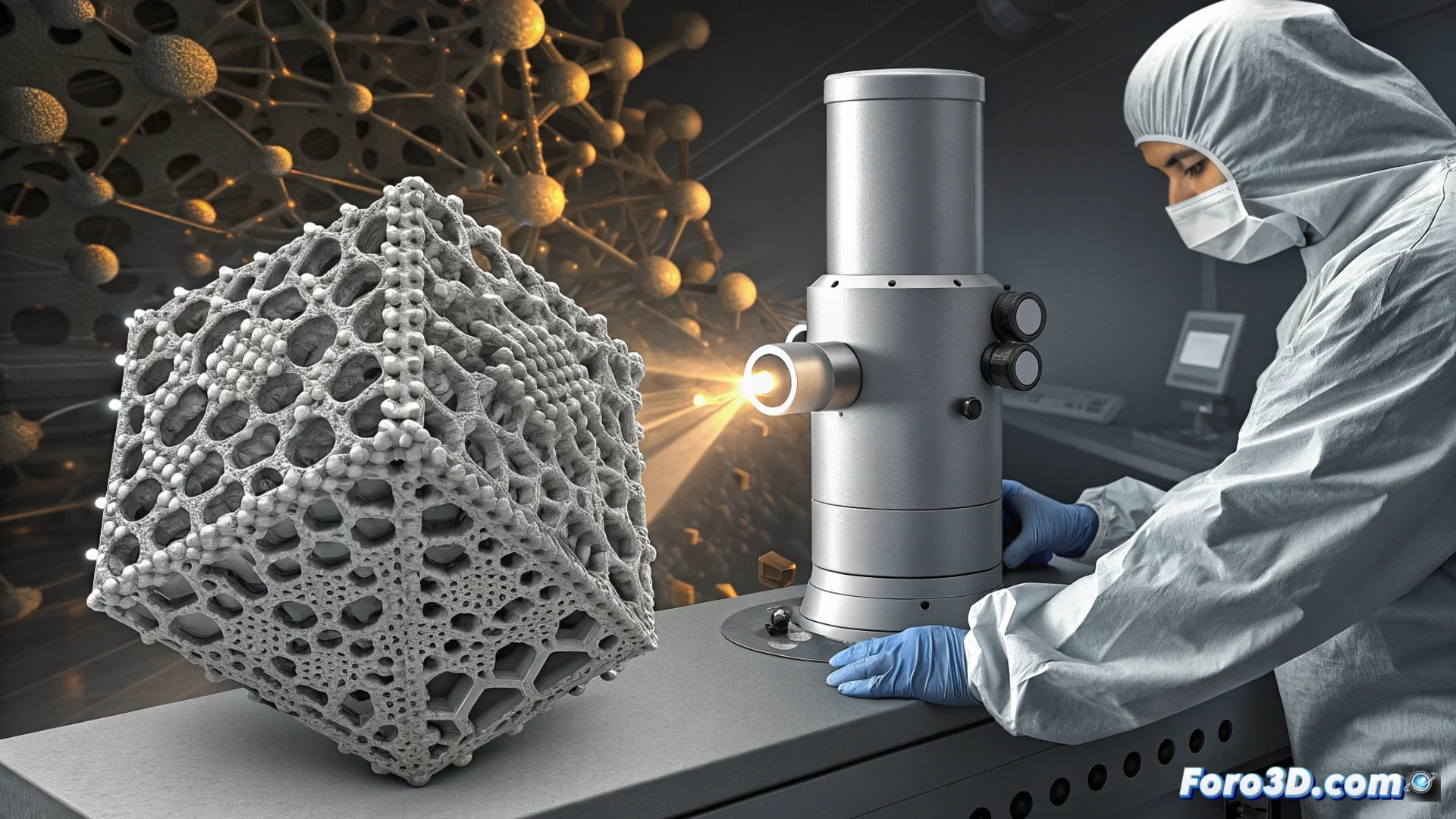

A team from Nagoya University in Japan reveals an innovative method to produce aluminum alloys capable of operating under extreme heat conditions. This achievement is based on using metal additive manufacturing techniques, specifically laser powder bed fusion. The strategy enables the design of intricate microstructures that conventional processes cannot replicate, resulting in a material that retains its mechanical properties under thermal stress 🔥.

Combining Aluminum with Rare Earth Elements for Stable Structures

The researchers process aluminum powder to which they add precise amounts of scandium and zirconium. During the 3D printing cycle, the laser beam selectively melts the powder, generating a microstructure with fine grains and a homogeneous distribution. This internal configuration is fundamental for the compound to resist deformation when exposed to intense heat. Standard aluminum alloys typically soften and lose strength above 200°C, but this new material significantly extends that threshold.

Key Advantages of the Additive Manufacturing Process:- Allows creating complex internal geometries that optimize thermal resistance.

- Achieves a uniform distribution of alloying elements in the microstructure.

- Facilitates producing components with lightweight designs that would be unfeasible with traditional methods.

Laser 3D printing not only builds the part but also defines its future performance by controlling the structure from the inside.

Applications in Advanced Engineering

This progress in materials science enables the design of lighter and more efficient parts for industries where weight and heat exposure are decisive. It could be used to manufacture components in aviation engines, turbines, or automotive exhaust systems that require less cooling or operate in more aggressive environments.

Sectors That Can Benefit:- Aeronautics: For structural parts and engine components that withstand thermal cycles.

- High-Performance Automotive: In engine parts and exhaust systems where reducing weight is crucial.

- Energy: In components for turbines operating at high temperatures.

A Future with Smarter and Lighter Materials

The technique presented by Nagoya University demonstrates how metal 3D printing can overcome the limitations of existing materials. By integrating rare earth elements and controlling the microstructure during manufacturing, it opens the door to a new generation of aluminum alloys. These not only resist heat but also allow optimizing the shape of parts to lighten them without impairing their function, marking a clear path for the next evolution in advanced manufacturing ⚙️.