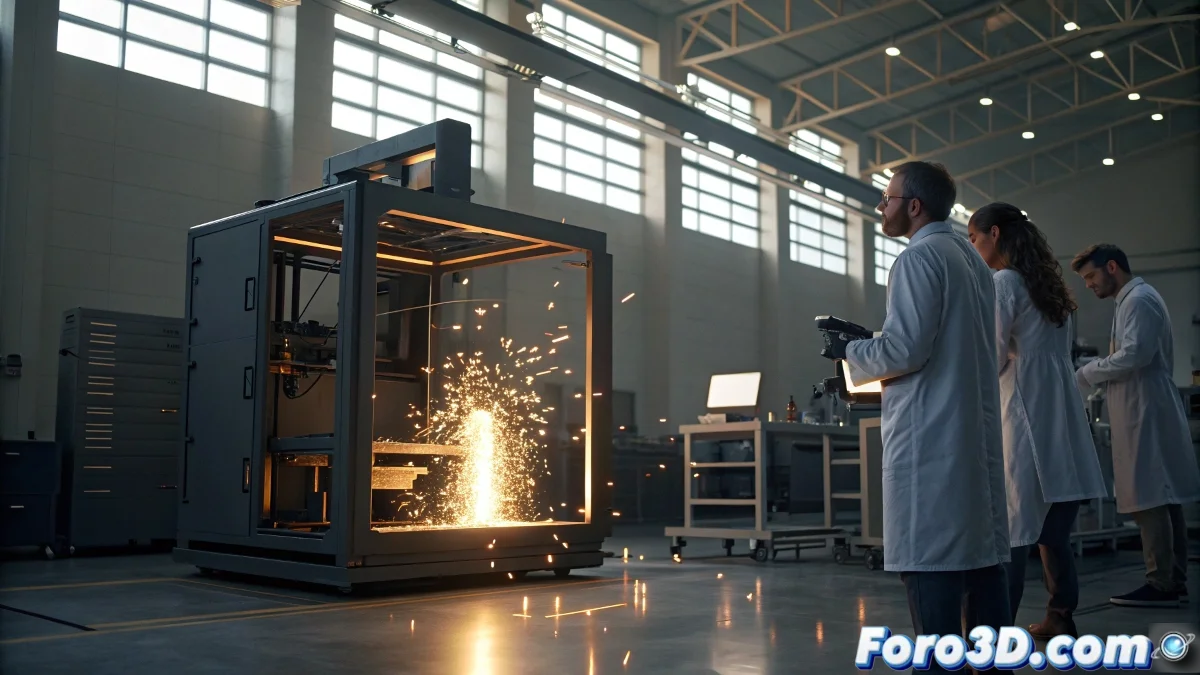

When academia arms itself with cutting-edge industrial technology

Missouri University of Science and Technology (Missouri S&T) has made a significant investment in additive manufacturing capabilities by acquiring a Nikon SLM500 metal 3D printer. This industrial-grade machine represents a quantum leap in the institution's research capabilities, allowing students and faculty to work with technology that was previously mainly in the hands of large corporations and government laboratories. The acquisition positions Missouri S&T as a center of excellence in advanced manufacturing within the North American academic landscape.

The Nikon SLM500 is not a common 3D printer: it is a selective laser melting manufacturing system capable of processing a wide range of industrial metals, from aluminum and titanium alloys to nickel superalloys and tool steels. With a build volume of 500x280x365 mm, it can produce substantial components that will be used both in fundamental research and in applied projects with industrial partners. The system's precision allows for the creation of complex internal geometries that are impossible to manufacture using traditional methods.

Key technical capabilities of the equipment

- Multiple lasers enabling high productivity and complex geometries

- Real-time process control system for consistent quality

- Advanced materials handling including reactive and refractory metals

- Software integration for topological and generative optimization

The impact on training future engineers

For Missouri S&T students, this acquisition represents an invaluable opportunity to gain hands-on experience with manufacturing technology that is defining the industrial future. Where they previously learned about metal 3D printing theoretically or through lower-capacity equipment, they can now design, print, and test real components that could end up in aerospace, medical, or automotive applications. This early exposure to cutting-edge technology gives them a significant competitive advantage in the job market.

The best way to predict the future is to have the tools to create it

Research lines that will benefit immediately include the development of new alloys specific to additive manufacturing, optimization of process parameters for different applications, and study of microstructures resulting from the laser melting process. The ability to produce customized samples for testing will dramatically accelerate materials science research, enabling rapid iterations that previously took months using conventional manufacturing methods.

Research areas that will be enhanced

- Metal composite materials with region-specific customized properties

- Lattice structures for advanced lightweighting applications

- Components for extreme environments such as turbines and space engines

- Customized medical implants with integrated bioactive surfaces

The strategic importance of this acquisition extends beyond the university campus. Missouri S&T can now establish deeper collaborations with companies seeking to explore metal additive manufacturing capabilities but lacking internal resources to invest in equipment of this magnitude. This symbiosis between academia and industry accelerates the adoption of advanced technologies while providing students with exposure to real-world engineering challenges.

Those who thought universities were several steps behind industry in manufacturing technology probably didn't count on institutions like Missouri S&T equipping themselves with machinery that many companies would envy 🏭