When coolant flows through the veins of silicon

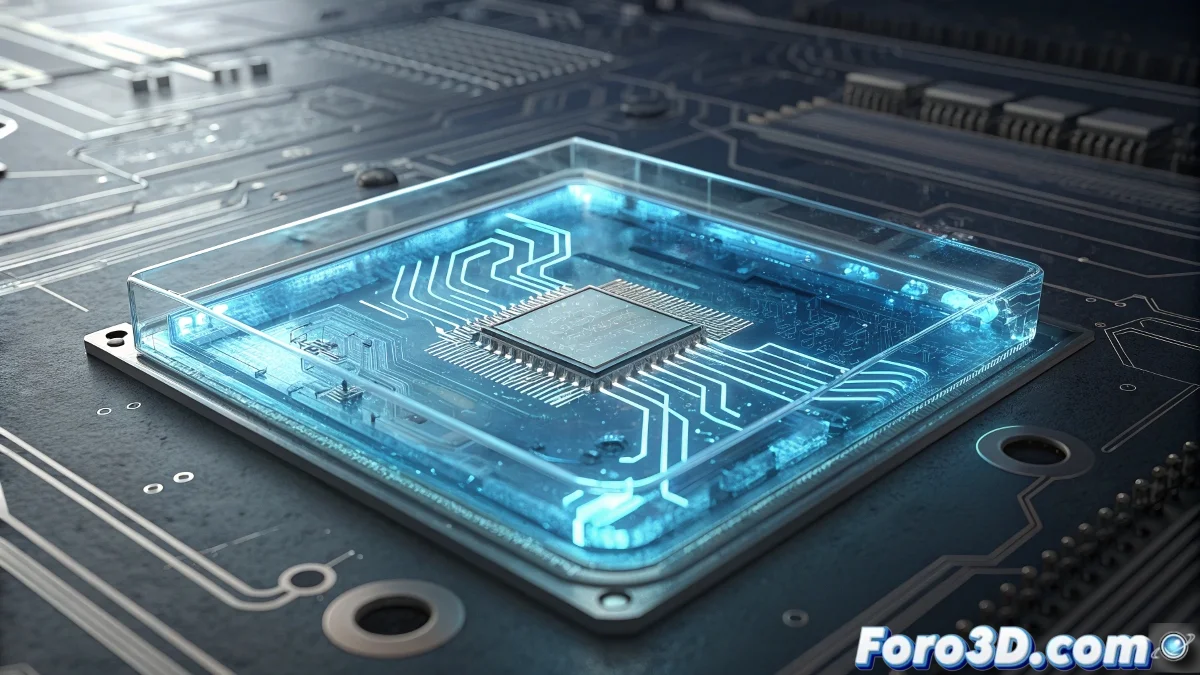

Microsoft has decided to redefine one of the most basic principles of modern computing: how to keep processors cool. The company has developed a technology that etches cooling microchannels directly into the silicon of chips, eliminating the thermal barriers that have traditionally limited processor performance. This radical approach could solve one of the greatest challenges of Moore's Law: how to dissipate heat in increasingly smaller and denser components.

The innovation represents a paradigm shift by treating heat not as an external problem but as a fundamental design variable. Instead of adding cooling solutions after manufacturing the chip, Microsoft is integrating the cooling system into the semiconductor architecture itself. Preliminary results show dramatic improvements in thermal efficiency that could enable significantly higher clock speeds. 🔥❄️

The future of processor performance is not in making them faster, but in keeping them cooler for longer

The engineering behind the thermal revolution

This approach solves fundamental problems of conventional thermal dissipation through unprecedented integration.

- Capillary microchannels that distribute coolant at a microscopic level

- Porous structures that maximize contact area with the liquid

- Compatible materials that prevent corrosion and thermal degradation

- Flow systems that prevent bubbles and hot spots

The technology allows the coolant to reach the most critical areas of the chip directly, those that generate the most heat and have traditionally been the hardest to cool efficiently.

Implications for the future of hardware

This breakthrough could have profound consequences across multiple industry segments.

- Data centers with significantly higher computational density

- Mobile devices with sustained performance without thermal throttling

- Video game consoles capable of maintaining boost frequencies indefinitely

- Artificial intelligence with larger models running locally

For content creators and workstation users, this could mean faster renders and more complex simulations without traditional thermal limits.

The challenge of scaling manufacturing

Commercial implementation will depend on the ability to scale this technology economically. The required microfabrication processes are considerably more complex than traditional methods.

Microsoft will need to demonstrate that it can produce these integrated cooling chips at a cost that justifies the performance improvements. If it succeeds, we could be witnessing one of the most significant advances in processor design in the last decade. The race to master thermal management has just accelerated dramatically. 💻

And if this technology works as well as it promises, extreme overclockers might soon need licenses for handling hazardous liquids... instead of just building-sized heatsinks 😉