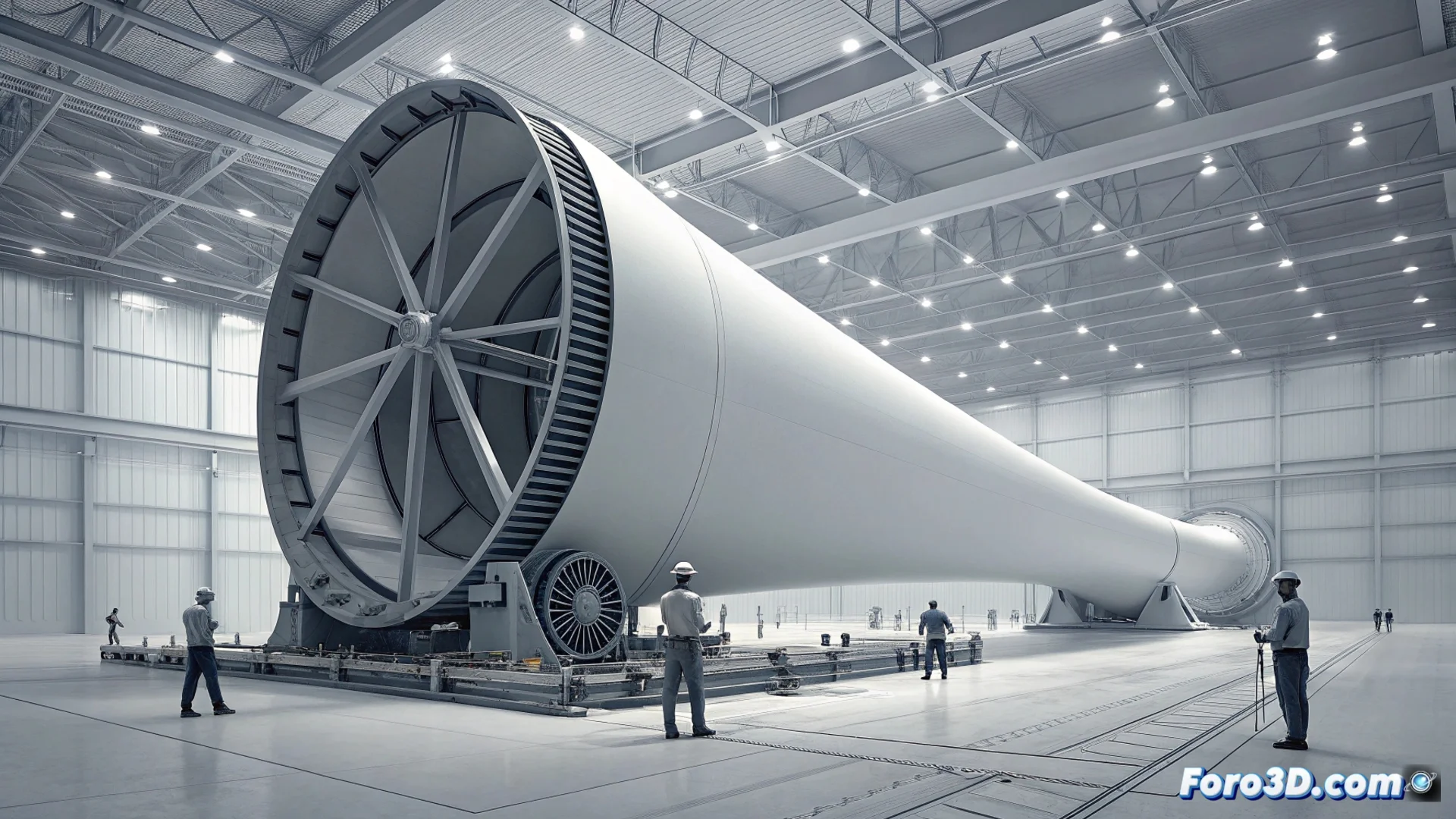

MHI Vestas Manufactures Tools for Wind Turbine Blades Using 3D Printing

The company MHI Vestas has integrated additive manufacturing into its process for building offshore wind turbines. They use this technology to produce manufacturing tools and specific templates that are used when assembling the gigantic blades of their V164 model. This technological shift marks a milestone in the offshore renewable energy industry 🌀.

Replacing Traditional Methods with Additive Manufacturing

The blades, which measure eighty meters, require enormous components and extreme precision. Previously, the necessary tools were made from wood or metal. Now, 3D printing offers a direct alternative, transforming how the production line is organized for these critical elements.

Key Advantages of Adopting 3D Printing:- Reduce Weight: Printed parts are lighter, simplifying handling and manipulation in the work environment, improving safety and operational efficiency.

- Accelerate Production: Tools can be manufactured much faster than with conventional machining techniques, speeding up the entire blade manufacturing cycle.

- Ensure Precision: Additive technology achieves tight tolerances, ensuring each blade meets the design specifications necessary for operation in demanding marine conditions.

Implementing 3D printing allows us to respond agilely to sector demands, creating or adapting designs without relying on lengthy and costly processes.

Transforming the Wind Supply Chain

This approach not only optimizes how a component is produced but impacts the entire chain for generating renewable energy. By being able to produce tools on demand and with customized designs, dependence on extensive inventories and complex logistics is reduced.

Impact on the Industry:- Optimize Manufacturing of a critical and large-scale component.

- Respond Flexibly to changing project and market requirements.

- Make More Efficient and resilient the supply chain for offshore wind energy.

A Future Built Layer by Layer

MHI Vestas' decision underscores the crucial role of industrial 3D printing beyond prototypes. It demonstrates that it can be used to manufacture the tools that, in turn, build massive and reliable energy infrastructure. This case sets a precedent for optimizing other heavy manufacturing processes where weight, time, and accuracy are decisive factors ⚙️.