When Additive Technology Meets Atomic Energy

The nuclear industry, known for its extremely rigorous safety standards, is taking a historic step toward modernization. ⚛️ The collaboration between Kinectrics and Burloak Technologies has successfully demonstrated that metal 3D printing is viable for manufacturing critical components used in nuclear reactors. This milestone is not just a technical advancement; it is a revolution in the way manufacturing is conceived within a sector where precision and reliability are absolutely non-negotiable.

Advantages of Additive Manufacturing in High-Demand Environments

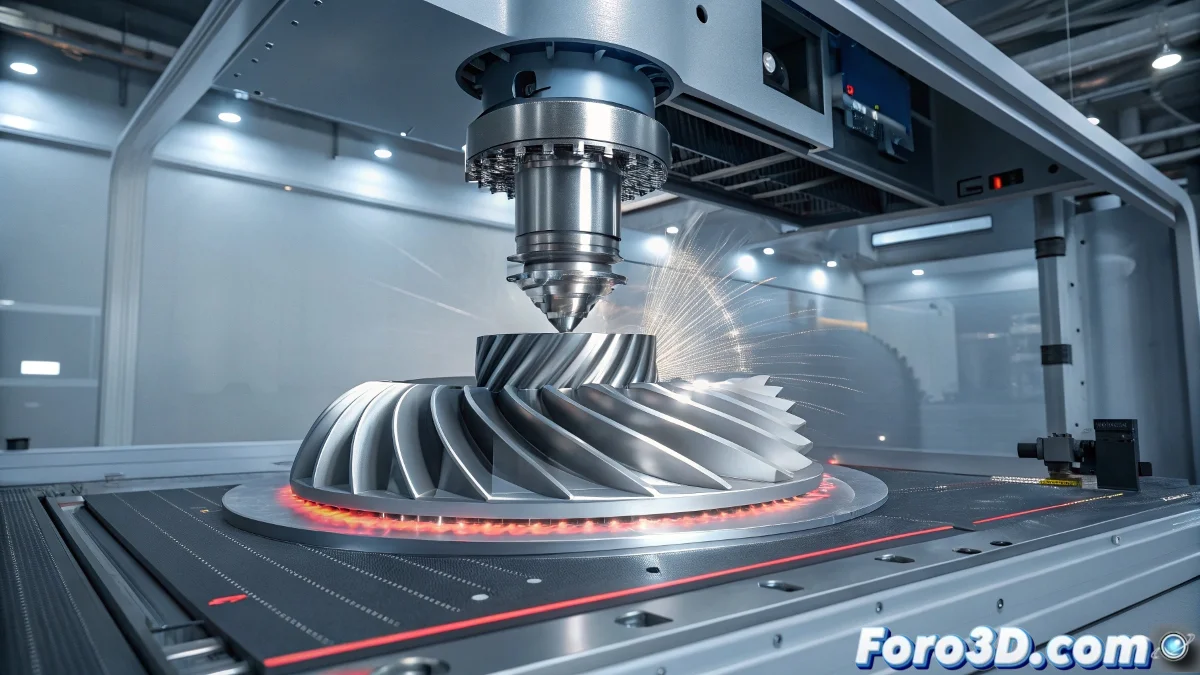

Metal 3D printing, or additive manufacturing, enables the creation of complex and internal geometries that would be unfeasible with traditional machining methods. 🏭 This translates into more efficient parts, with optimized weight and minimal material waste. For the nuclear industry, where some components are unique and low-volume, this technology offers unprecedented agility, drastically shortening production times and enabling on-demand manufacturing.

This technology allows redesigning parts with function in mind, not the limitations of traditional manufacturing.

A Strategic Collaboration for the Energy Future

The success of this demonstration is based on the union of experts. Kinectrics brings its deep knowledge in nuclear engineering and materials qualification, while Burloak Technologies contributes its cutting-edge expertise in metal 3D printing processes. 🤝 Together, the companies have subjected the printed components to a battery of tests to verify their strength, durability, and compliance with regulatory standards, paving the way for their formal adoption.

- Waste Reduction: Additive manufacturing generates significantly less waste than subtractive machining.

- Customization: Ability to produce customized or spare parts quickly.

- Safety: Components can be designed with better structural and performance properties.

The Long-Term Impact on Nuclear Energy

Integrating 3D printing into the nuclear supply chain promises a future with reduced operating costs and greater availability of critical components. 💡 This is crucial for extending the life of existing plants and for the construction of next-generation reactors. The ability to manufacture parts on demand could mitigate supply bottlenecks and improve the resilience of energy infrastructure.

It seems that even the most conservative industry can embrace innovation when the reward is greater precision and efficiency. 😉 Who would have thought that the energy of the future would be built layer by layer.