Meshmixer and its Inspector function: automatic 3D model repair

The Meshmixer tool suite incorporates an intelligent diagnostic system that revolutionizes the preparation of files for 3D printing. This automatic Inspector identifies and corrects the most common defects in digital models through optimized processes that guarantee geometric integrity 🛠️.

Error detection and correction mechanism

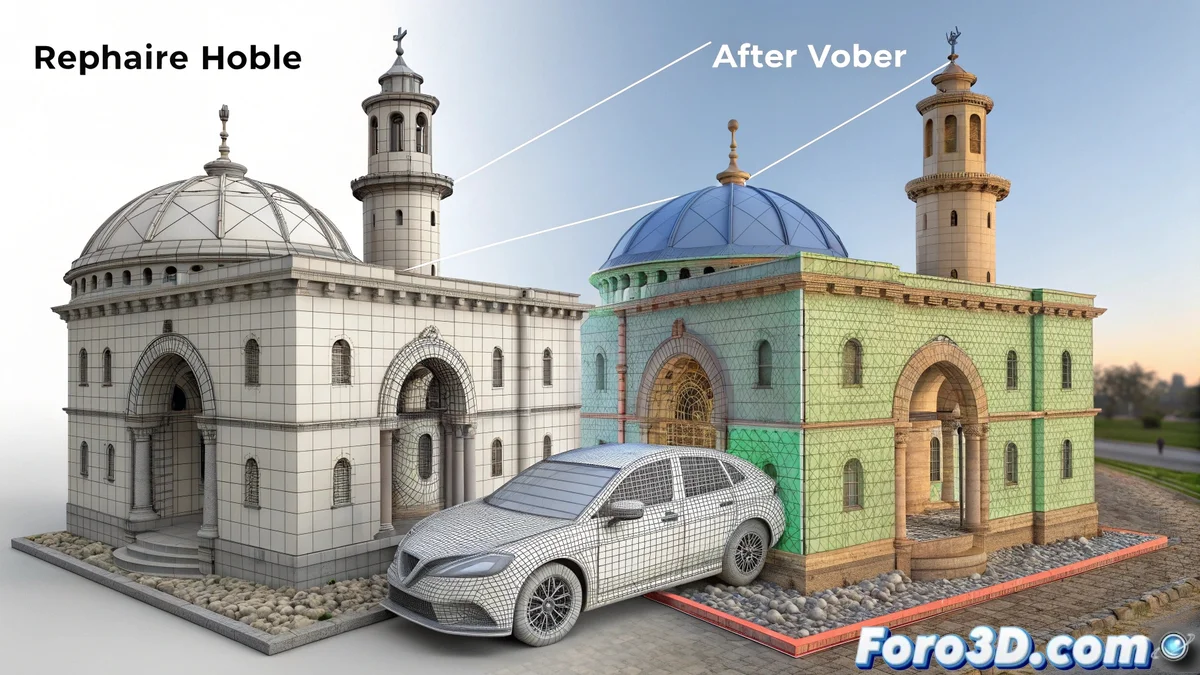

When running the Inspector function, the software performs a comprehensive scan of the three-dimensional mesh, locating problematic areas through a color-coding system. Surface discontinuities are marked in intense red tones, inverted normals in characteristic blue, while non-manifold structures are highlighted in bright yellow. Automatic repair reconstructs the affected topology and seals unwanted openings.

Frequently detected problems:- Holes in the mesh - Discontinuities that interrupt the model's continuous surface

- Inverted geometry - Faces with incorrect orientation that affect volume calculations

- Loose edges and non-manifold - Structures that prevent proper additive manufacturing

Meshmixer's Inspector acts as a specialized technician that not only identifies structural faults but also implements immediate solutions before they compromise the printing process.

Integration into 3D printing workflows

This utility becomes a fundamental link in the model preparation chain, especially when geometric perfection determines the success of manufacturing. Designers can quickly validate the structural viability of their creations before sending them to printers, minimizing failures related to defective meshes. Additionally, it demonstrates exceptional compatibility with files from various sources such as 3D scans and online repositories.

Main operational advantages:- Pre-print verification - Dramatically reduces error rates during manufacturing

- Multi-platform compatibility - Works efficiently with standard industry formats

- Process automation - Minimizes manual intervention in tedious corrections

Impact on design productivity

The implementation of Meshmixer's Inspector represents a significant advance for users who require immediate solutions without delving into technical modeling complexities. This tool not only optimizes times but also ensures consistent professional results, becoming the indispensable ally for those seeking excellence in 3D printing without excessive complications ✅.