Merck and AMCM Partner to Produce Tablets with 3D Printing

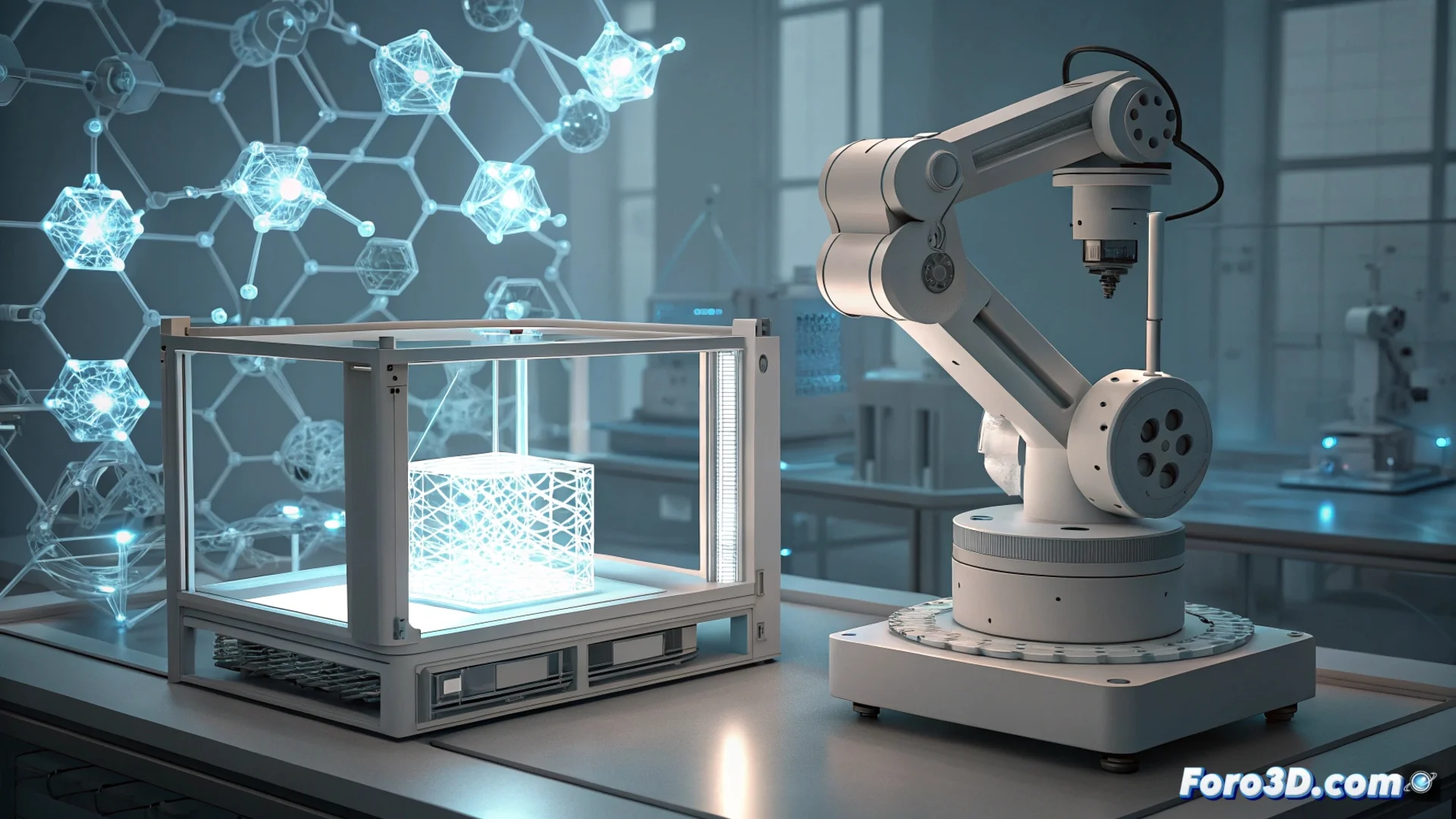

Two giants in their respective fields join forces. The pharmaceutical company Merck and the additive manufacturing specialist AMCM have formalized a strategic collaboration. Their main goal is to develop and scale the manufacturing of tablets using 3D printing techniques, a step that could transform how medications are produced. 🧪

Precise Dosing through Powder Bed Fusion

The core of this initiative is powder bed fusion 3D printing technology. This process not only shapes the external form of the pill but also allows for the design of complex internal structures. These structures are key to managing how and when the active ingredient is released in the body. Thus, the dose and absorption rate can be precisely adjusted, which is vital for treatments that require specific release profiles.

Key advantages of this approach:- Precise dose control: Each tablet can contain the exact amount of drug required.

- Programmed release: Internal structures allow for custom dissolution profiles.

- Complex geometries: Shapes can be manufactured that would be impossible with traditional compression methods.

This alliance seeks to explore the advantages of additive manufacturing to create more precise and personalized medications.

Accelerating the Path from Lab to Patient

The collaboration is not limited to manufacturing but aims to optimize the entire cycle. By integrating 3D printing into the early stages, they seek to drastically reduce the time it takes to bring a new drug from concept to the patient who needs it. This agile method also facilitates the production of small batches for clinical trials or the creation of medications tailored to individual needs.

Optimization cycle objectives:- Reduce development times: Streamline the path from design to production.

- Facilitate small batches: Produce limited quantities for clinical studies efficiently.

- Enable personalization: Create treatments tailored to specific patient profiles.

The Future of Personalized Medication

This alliance points to a future where pharmacological treatments could be as unique as the patients themselves. Beyond functionality, the technology even opens the door to details like 3D brands or logos integrated into the tablet itself. The union of Merck's pharmaceutical expertise and AMCM's technical knowledge could redefine medication production standards. 💊