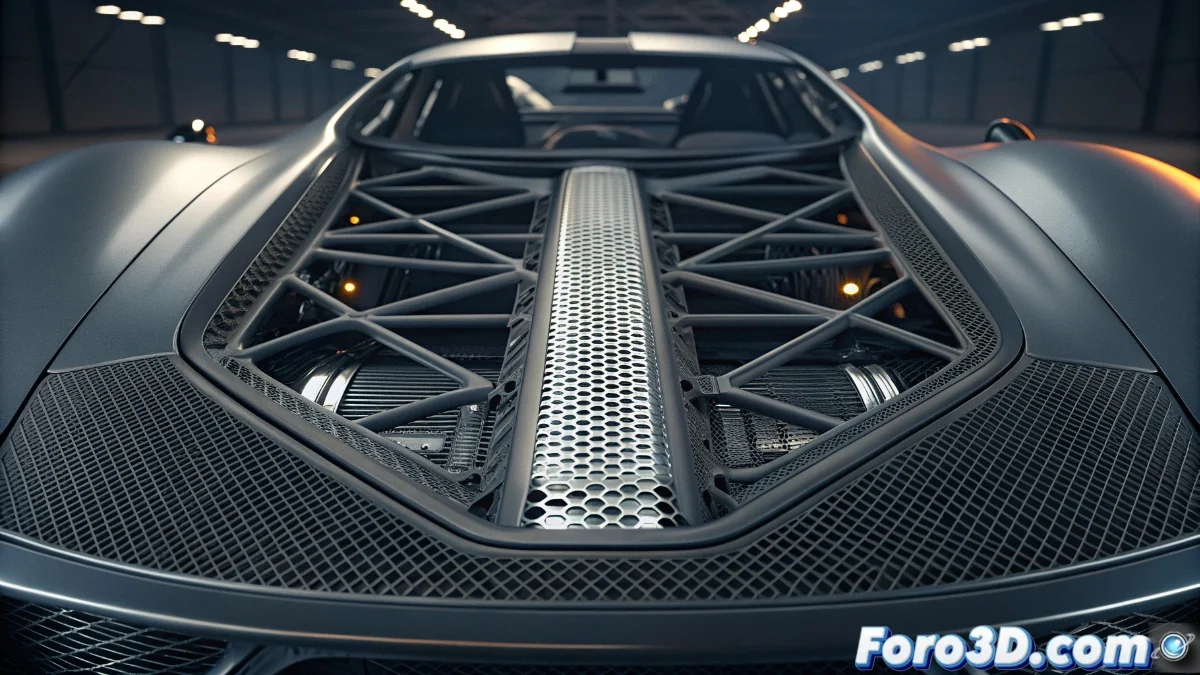

McLaren Uses Additive Manufacturing in Speedtail Development

Additive manufacturing technology is revolutionizing the high-performance automotive industry, and McLaren is strategically implementing it in the development of its exclusive Speedtail hypercar. This methodology allows the creation of specialized components that combine minimum weight with maximum thermal resistance, essential characteristics for a vehicle seeking to break speed records 🚀.

Competitive Advantages of 3D Printing with Titanium

Additive manufacturing provides McLaren engineers with unprecedented design freedom, allowing the creation of parts with optimized internal geometries that would be technically impossible to produce using conventional methods. The use of aeronautical-grade titanium ensures that these components maintain their structural integrity even under the most extreme conditions of temperature and mechanical stress 🔥.

Specific Applications in the Speedtail:- Cooling ducts with organic internal channels that maximize airflow

- Structural supports with lattice design that reduce weight without compromising rigidity

- Exhaust components that efficiently dissipate heat during high-speed operation

"Additive manufacturing allows us to materialize aerodynamic concepts that previously only existed in computer simulations" - McLaren Advanced Engineering Chief

Impact on Aerodynamic Performance

The complex geometry enabled by 3D printing has been fundamental in achieving the Speedtail's aerodynamic efficiency goals. Engineers have been able to integrate continuous curved surfaces and strategic internal cavities that significantly reduce air resistance while improving high-speed stability ✈️.

Benefits in the Final Design:- Reduction of turbulence through optimized aerodynamic profiles

- Improvement in thermal management of critical vehicle systems

- Aesthetic-functional integration where every element serves a dual purpose

The Future of Manufacturing in Hypercars

The implementation of cutting-edge technologies like additive manufacturing represents a turning point in the high-performance automotive industry. McLaren demonstrates that extreme customization and component optimization through 3D printing are not only possible but essential to surpass the current limits of vehicle performance. This technological approach sets a new standard for what is achievable in terms of efficiency, lightness, and durability in ultra-high-performance automobiles 🏎️.