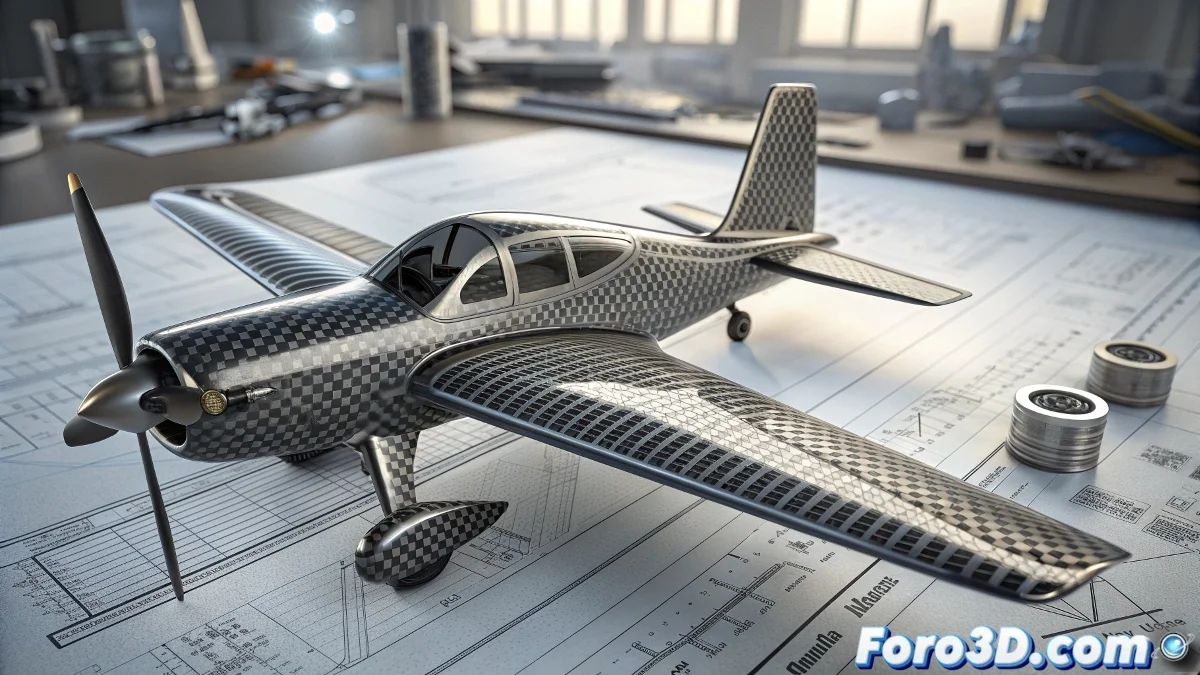

Markforged Certifies 3D Printing for VIP Aircraft with Maximum Safety Standards

Industrial 3D printing reaches new horizons in executive aviation through the certification of critical parts manufactured with additive technology. Markforged has set a fundamental precedent by demonstrating that its components meet the most demanding requirements of the aeronautical industry 🛩️.

Advanced Materials for Critical Applications

The key to success lies in the development of specialized composite materials that offer exceptional strength-to-weight ratios. These continuous fiber reinforced composites ensure the structural integrity necessary to withstand extreme flight conditions.

Competitive Advantages of Certified Additive Manufacturing:- Reduction of up to 80% in production times compared to traditional machining

- Complete customization of components without additional tooling costs

- Absolute traceability of each part through digital quality control systems

The certification of 3D printed parts for VIP aircraft marks a turning point in the adoption of additive manufacturing for safety-critical applications

Validation Processes and Quality Control

Each component undergoes rigorous verification protocols that include destructive and non-destructive tests. The standardized processes ensure batch-to-batch repeatability, maintaining the required dimensional and mechanical consistency.

Currently Certified Components:- Structural supports for cabin systems

- Brackets and fixings for avionics

- Interior customization elements for executive comfort

Future of Aeronautical Manufacturing

This certification establishes 3D printing as a viable alternative to conventional methods, not only for prototyping but for final production of critical components. The path is open to expand these certifications to more applications within the aerospace industry ✈️.