Manufacturing Solar Panels in Orbit with 3D Printing

The race to deploy massive satellite constellations faces a critical bottleneck: energy. Sending all the solar panels needed for thousands of satellites from Earth is prohibitively expensive and radically limits their design. The solution may lie in manufacturing them directly in the vacuum of space, using additive manufacturing technology. 🚀

3D Printing Conquers Microgravity

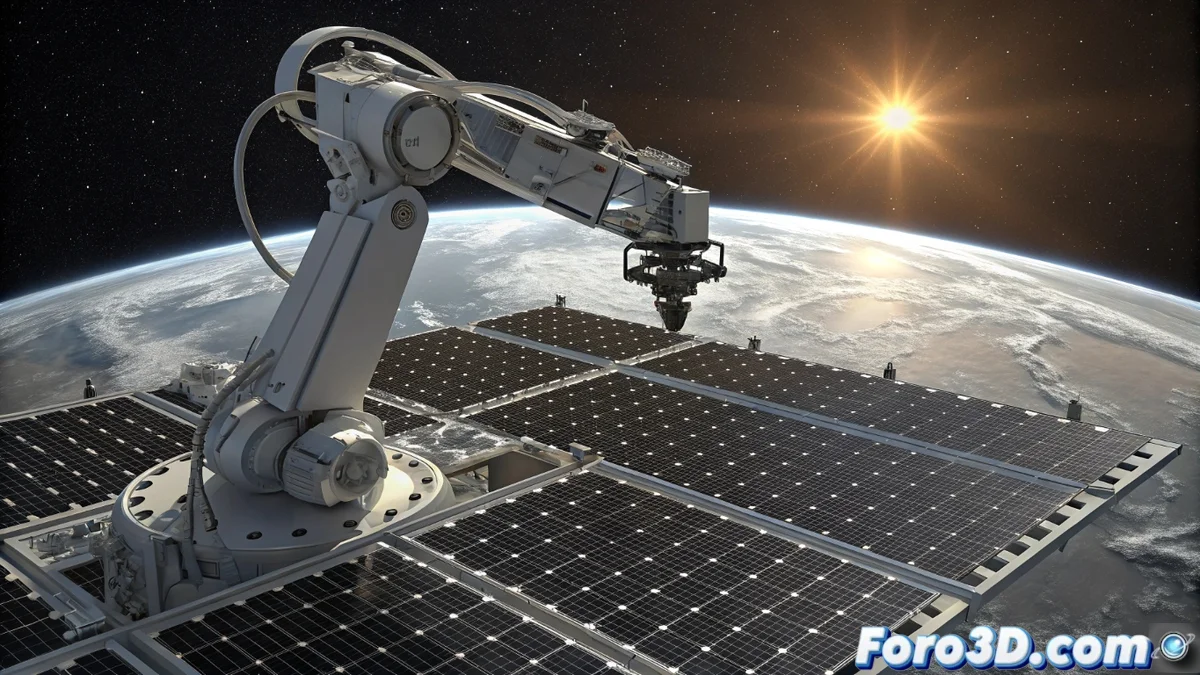

The key lies in adapting 3D printing processes to operate in microgravity. Instead of launching bulky and fragile structures, dense and compact raw materials are sent, such as advanced polymers or lightweight metal composites. Specialized robotic systems take this material and build the panel structures layer by layer in orbit. This method optimizes precious rocket volume and frees engineers to imagine designs that would be impossible to launch fully assembled, such as ultra-lightweight large-span structures.

Key advantages of manufacturing in space:- Reduce launch mass: Only raw material is transported, not the bulky final product.

- Enable innovative designs: Extensive and delicate frames can be created that wouldn't survive launch forces.

- Integrate components directly: Next-generation photovoltaic cells can be embedded during the printing process.

The biggest technical challenge isn't printing the panel, but preventing the printer from floating away because someone forgot to secure it. After all, in space, no one can hear you curse when you lose the screw.

Towards a Sustainable Cycle Beyond Earth

The ultimate goal goes beyond immediate savings. The aim is to establish a sustainable lifecycle for space infrastructure. Manufacturing in orbit eliminates launch mechanical stress, which can extend component lifespan. More advanced visions explore using in-situ obtained materials, such as asteroid dust or recycled metals from space debris, to further reduce dependence on Earth resources.

Materials and methods under research:- Radiation- and temperature-resistant polymers and composites: Lightweight materials designed to withstand extreme radiation and temperatures.

- Autonomous assembly systems: Robots that operate without constant human intervention to assemble printed structures.

- Orbital recycling techniques: Processes to convert space junk into useful raw material for printing.

A New Paradigm for Space Exploration

Manufacturing solar panels in orbit represents a paradigm shift. It's not just about optimizing a component, but about rethinking how we build and maintain infrastructure in space. For future communication constellations, Earth observation, or even lunar bases, this capability could be the factor that determines their economic and technical viability. Space thus becomes not only a destination, but the workshop where we craft our future among the stars. ✨