Machine Learning Improves Precision in 3D Printing of Carbon Nanotubes

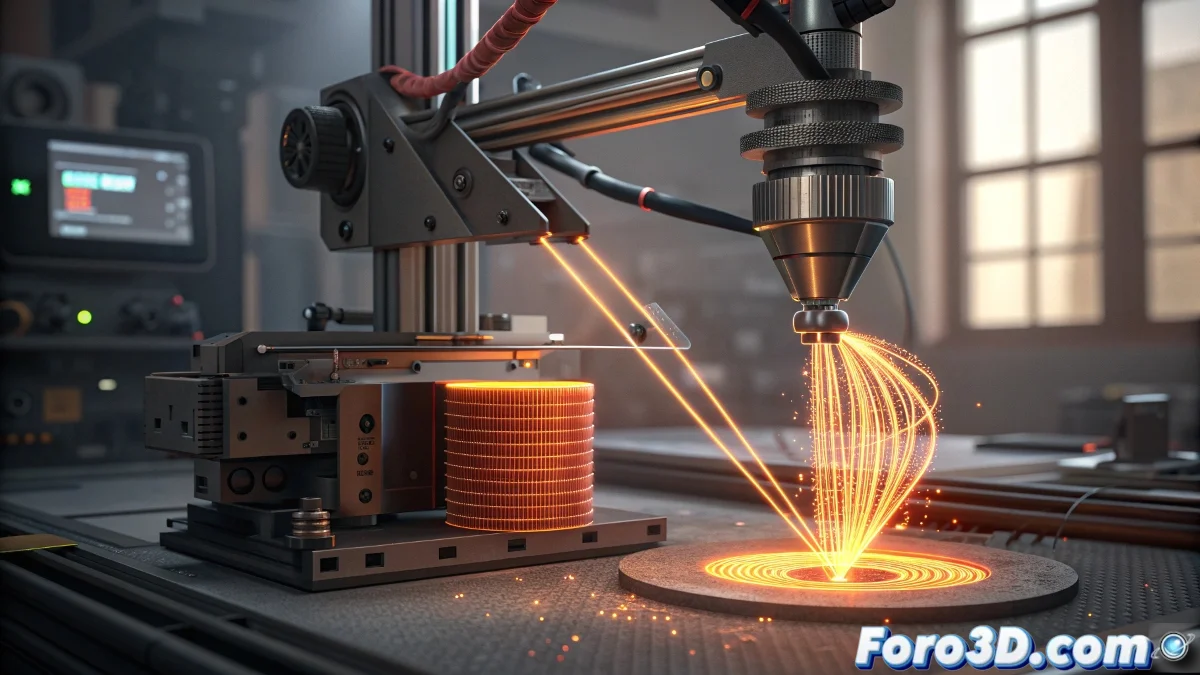

Artificial intelligence is revolutionizing the manufacturing of advanced materials by optimizing 3D printing processes at the nanoscale. Japanese researchers have demonstrated how machine learning can overcome traditional limitations in the production of carbon nanotube structures 🧠.

Intelligent Algorithms for Process Control

The system uses predictive algorithms that continuously analyze multiple variables during printing. These machine learning models automatically adjust critical parameters such as temperature and speed to maintain optimal CNT filament quality.

Parameters Optimized by AI:- Deposition speed dynamically controlled based on material viscosity

- Extrusion temperature adjusted in real-time to prevent degradation

- Filament tension maintained within precise ranges for structural integrity

The integration of machine learning into carbon nanotube manufacturing represents a significant advance towards the consistent production of high-quality nanostructured materials

Applications in Electronics and Composite Materials

The greater uniformity in printed structures enables more demanding applications in flexible devices and advanced electronic systems. The improved mechanical and electrical properties open new possibilities in multiple industries 💡.

Benefited Application Fields:- Wearable electronics with integrated nanotube circuits

- Ultralight composite materials for aerospace

- High-sensitivity sensors for medical devices

Future of Intelligent Nanomaterial Manufacturing

This synergistic combination between artificial intelligence and additive manufacturing establishes a new paradigm in the production of advanced materials. The approach not only improves current precision but also significantly accelerates the development of new nanomaterials with customized properties 🔬.