Development of a Low-Consumption 5G Antenna

Researchers at the University of Notre Dame are working on a next-generation antenna for 5G networks. This technology uses artificial dielectric materials manufactured via 3D printing, allowing for reduced energy consumption without affecting performance. The project is led by Jonathan Chisum and has the backing of the United States Army.

An Innovative Design to Reduce Energy Consumption

Current 5G networks require high energy consumption, with each base station using an amount comparable to that of several dozen households. The Notre Dame team has developed an antenna with a Gradient Index (GRIN) lens for millimeter waves that enables operation across all 5G frequency bands using a single device. This design eliminates the need for multiple antennas and high-energy-consumption chips.

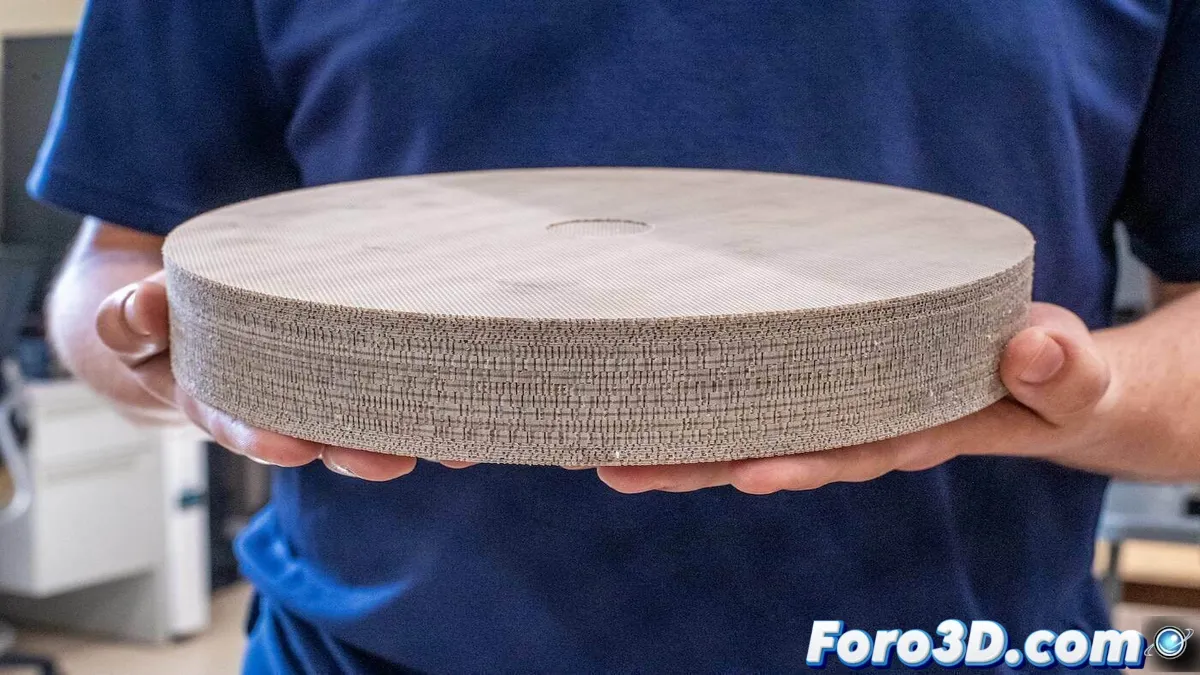

Application of 3D Printed Materials

Each antenna is fabricated from a 3D printed dielectric material with a gyroid-type cell structure. The production of these prototypes is done layer by layer through a detailed process that lasts approximately 100 hours. The internal structure optimizes wave propagation without requiring additional electronic components to adjust frequencies.

Impact on Military and Civilian Sectors

The design of this antenna allows for its use in both military and civilian spheres. For the armed forces, the ability to operate across a wide range of frequencies facilitates communication in various regions of the world. In the commercial sector, the reduction in energy consumption and the simplification of hardware can lower operational costs and accelerate the deployment of millimeter-wave 5G networks.

Collaboration with Industry and Next Steps

The Notre Dame team seeks to improve manufacturing processes through 3D printing and consolidate production at scale. In this effort, they are collaborating with Cheshir Industries, a company founded by Chisum and university alumni, and 3D Fortify, which specializes in the design and manufacturing of radio frequency components. The goal is to achieve a technology that combines efficiency, low cost, and ease of implementation in the market.