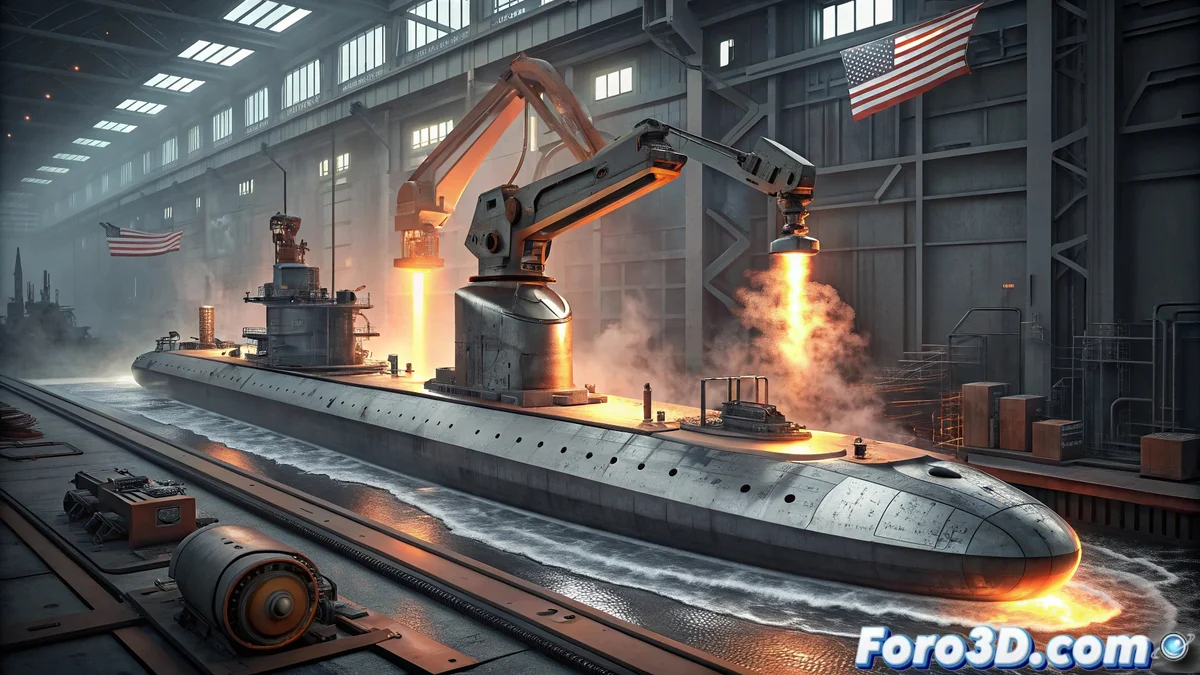

Lincoln Electric Revolutionizes Nuclear Submarine Manufacturing with Metal 3D Printing

The American corporation Lincoln Electric is radically transforming the production of components for nuclear submarines through the implementation of large-scale metal 3D printing. This innovative technology enables the manufacture of parts with extremely complex geometries that are impossible to achieve using conventional manufacturing methods, all while preserving the most stringent military quality standards 🚀

Operational Advantages in Extreme Submarine Environments

The additive manufacturing process employs specialized alloys specifically designed to withstand the most adverse conditions encountered in ocean depths. These materials must endure everything from abyssal pressure to marine corrosion, ensuring the structural integrity of components during extended missions.

Key Benefits of Additive Manufacturing:- Creation of complex internal geometries impossible to machine

- Elimination of conventional design constraints

- Weight optimization without compromising structural strength

"Metal 3D printing represents a paradigm shift in how we conceive and produce critical components for national defense" - Naval Technology Specialist

Cost Optimization and Reduction in Manufacturing Times

This project generates significant savings by eliminating multiple stages of the traditional manufacturing process, such as the creation of complex molds and specialized tooling. Production times decrease dramatically because parts emerge directly from 3D printers with minimal secondary machining requirements.

Impact on the Naval Supply Chain:- Agile response to urgent requirements from the U.S. Navy

- On-demand production of critical components

- Optimized maintenance of the operational fleet

Strategic Strengthening of Industrial Autonomy

With this initiative, Lincoln Electric consolidates technological sovereignty in the strategic national defense sector. The ability to locally manufacture complex components reduces dependence on global supply chains that may present geopolitical vulnerabilities. This technology constitutes a strategic advancement that positions the United States at the forefront of military naval manufacturing, while also generating highly specialized employment in advanced technology industries 💪

The Future of Naval Manufacturing

Modern submarines now incorporate parts manufactured with more advanced technology than many contemporary electronic devices, with the advantage of not requiring periodic software updates. Metal 3D printing marks a turning point in the evolution of the naval defense industry, establishing new standards for efficiency, quality, and technological innovation 🌊