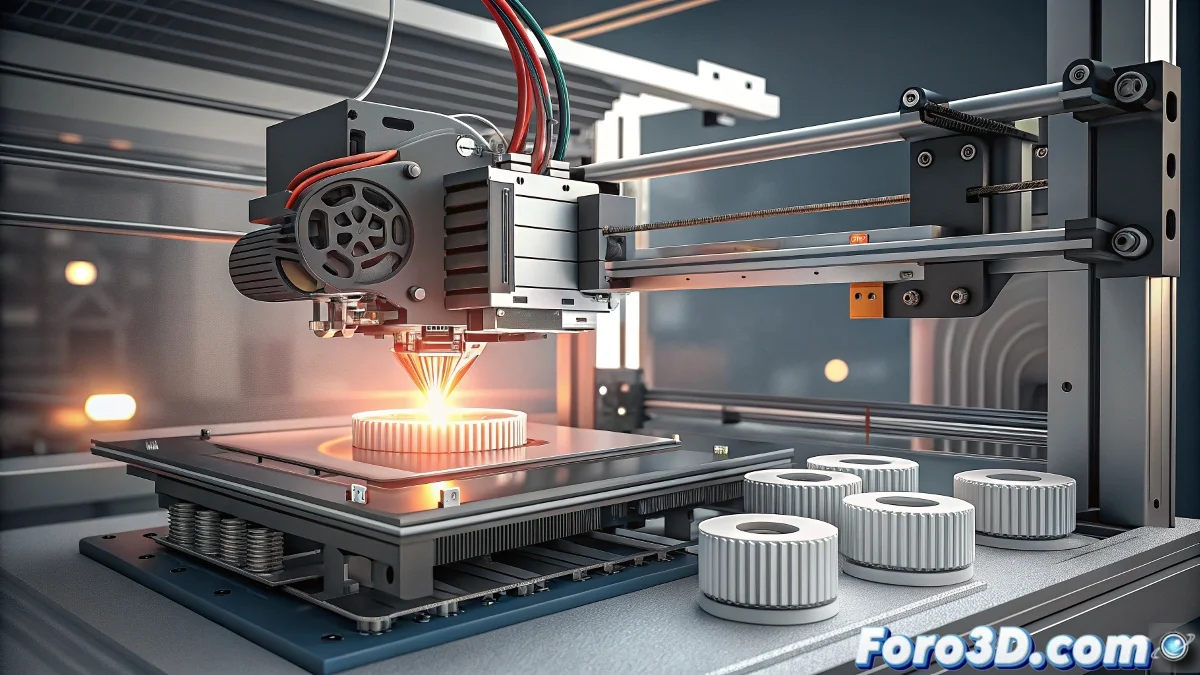

When 3D Printing Meets Crystallography

LCP represents a unique category in 3D printing materials, offering controllable anisotropic properties that challenge the conventions of traditional polymers. These liquid crystal polymers do not behave like conventional amorphous materials, but rather organize their molecular chains into ordered structures during processing. The result is a material that can exhibit radically different mechanical and thermal properties depending on the print direction, opening up unprecedented possibilities in the design of optimized components.

What makes LCP unique is its ability to self-organize during extrusion, creating an aligned microstructure that provides exceptional stiffness and strength in the flow direction. This controlled anisotropy allows for the design of parts where mechanical properties are specifically optimized for expected loads, something conventional isotropic materials cannot match. Its combination of low thermal expansion, high creep resistance, and dimensional stability makes it the preferred material for applications where every micron counts.

Revolutionary Technical Properties

- Controllable anisotropy with specific directional properties

- Thermal expansion coefficient similar to metals

- Exceptional dimensional stability under load and temperature

- Superior creep resistance even at high temperatures

The Art of Mastering Anisotropy

Printing with LCP requires a deep understanding of the material's rheology and directional behavior. This material demands temperatures between 340°C and 400°C, depending on the specific grade, and a heated bed between 120°C and 180°C. Print orientation becomes a critical design parameter, as it directly determines the final mechanical properties. Professionals use advanced simulation software to optimize the print path according to the expected loads on the final component.

LCP transforms the limitation of anisotropy into a powerful design tool

Managing crystallinity is fundamental to success with LCP. Print speed, temperature, and infill pattern directly influence the degree of molecular ordering and, therefore, the final properties. Experienced users develop specific profiles for different applications, adjusting parameters to maximize properties in critical directions. This ability to "program" properties through print parameters represents a significant advancement in additive manufacturing.

Applications of Extreme Precision

- Components for high-frequency connectors in telecommunications

- Precision guides and components for medical equipment

- Structural parts for drones and aerospace devices

- Components for automotive applications where weight and stiffness are critical

LCP's ability to maintain sub-millimeter tolerances under extreme conditions has found applications in industries where precision is non-negotiable. From RF connectors operating at gigahertz frequencies to components for surgical instruments that require absolute dimensional stability, this material offers the level of performance that justifies its processing complexity. The possibility of creating parts with tailored properties according to direction represents the final frontier in design for additive manufacturing. 📐

Working with LCP is like being a molecular orchestra conductor: every print parameter is a baton that directs how the polymer chains align, creating a symphony of perfectly orchestrated directional properties. 🎻

You can see this product and similar ones in the store