When 3D Printing Dives into Strategic Waters

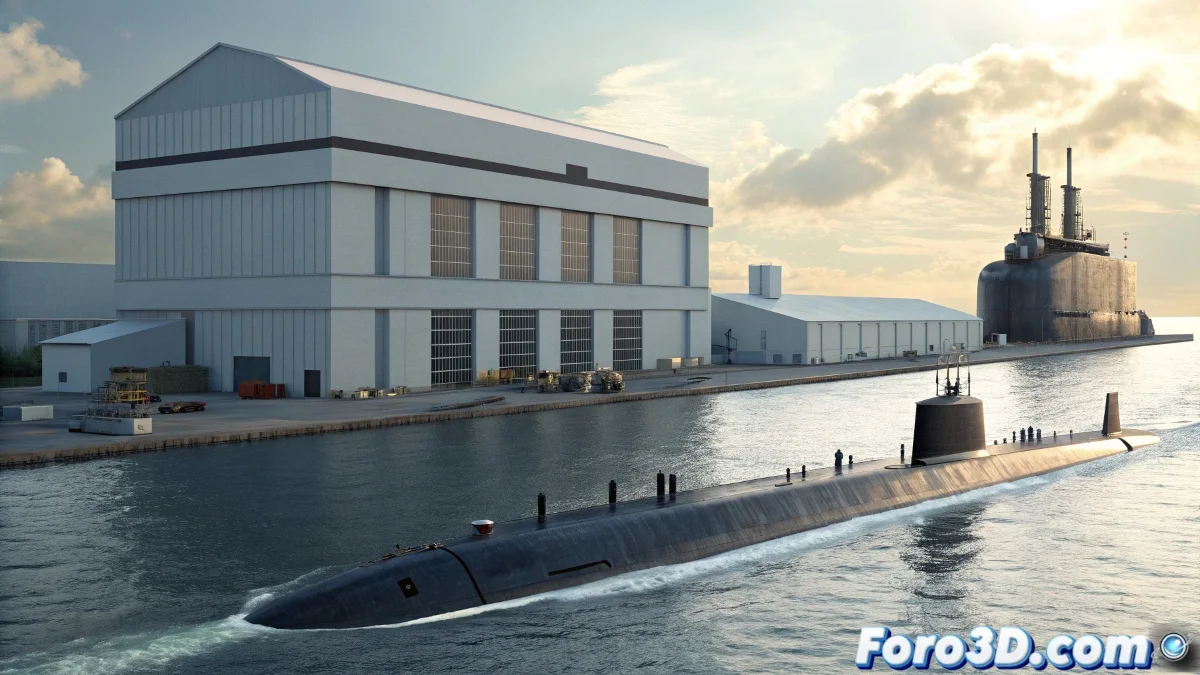

The US Navy is incorporating large-scale additive manufacturing into the production of its nuclear submarines, unlocking capabilities that redefine what's possible in military naval design and construction. This technology enables the creation of components with complex internal geometries that would be impossible to manufacture using traditional methods, optimizing both the performance and efficiency of these submarine colossi. What began as rapid prototyping has evolved into the production of critical parts that will navigate oceanic depths for decades.

The application of 3D printing in this context goes far beyond simply replacing existing methods. It is enabling fundamental redesigns where multiple components are consolidated into single pieces, eliminating joints that represented potential weak points and significantly reducing total weight. For submarines, where every kilogram counts and reliability is paramount, these advantages translate directly into improved operational capabilities and reduced maintenance over the vessel's lifespan.

Critical Applications in Naval Construction

- Impellers and pumps with hydrodynamically optimized flow channels

- Support structures with topology optimized for maximum strength-to-weight ratio

- Integrated piping systems that reduce welds and failure points

- Custom components for specialized nuclear propulsion systems

Logistics Transformed by Digital Manufacturing

One of the most significant impacts occurs in the supply chain and spare parts logistics. Traditionally, maintaining inventories of components for submarines that remain in service for 30+ years represented a monumental challenge. With additive manufacturing, many parts can be produced on demand as needed, reducing storage and eliminating the obsolescence of manufacturing tools that no longer exist. This agility is particularly valuable for older submarines where original manufacturers may have disappeared.

In the depths, every component must be perfect

The materials used in these applications are specialized alloys capable of withstanding the extreme conditions of the submarine environment: high pressure, saline corrosion, and prolonged exposure to seawater. Large-format 3D printers can work with naval-grade titanium, high-strength stainless steels, and superalloys that maintain their mechanical properties even after decades of service. Each piece undergoes rigorous non-destructive quality controls that ensure its structural integrity before installation.

Strategic Advantages for National Defense

- Reduction of times from years to months for critical components

- Rapid customization between different submarine classes without massive retooling

- Increased operational availability through accelerated repairs with on-demand parts

- Continuous innovation through rapid iteration of improved designs

This technological advancement arrives at a critical moment for the US Navy, which faces the need to modernize its submarine fleet while competing with emerging global powers. The ability to produce complex components more quickly and with higher performance provides a strategic advantage that transcends the merely technical. Additive manufacturing is becoming a pillar of naval technological superiority, demonstrating that civilian technologies can fundamentally transform defense capabilities when applied visionarily.

Those who thought 3D printing was only for prototypes and small objects probably didn't imagine it would be building the most critical components of the guardians of the oceanic depths 🚢