A Strategic Alliance to Revolutionize Mold Manufacturing

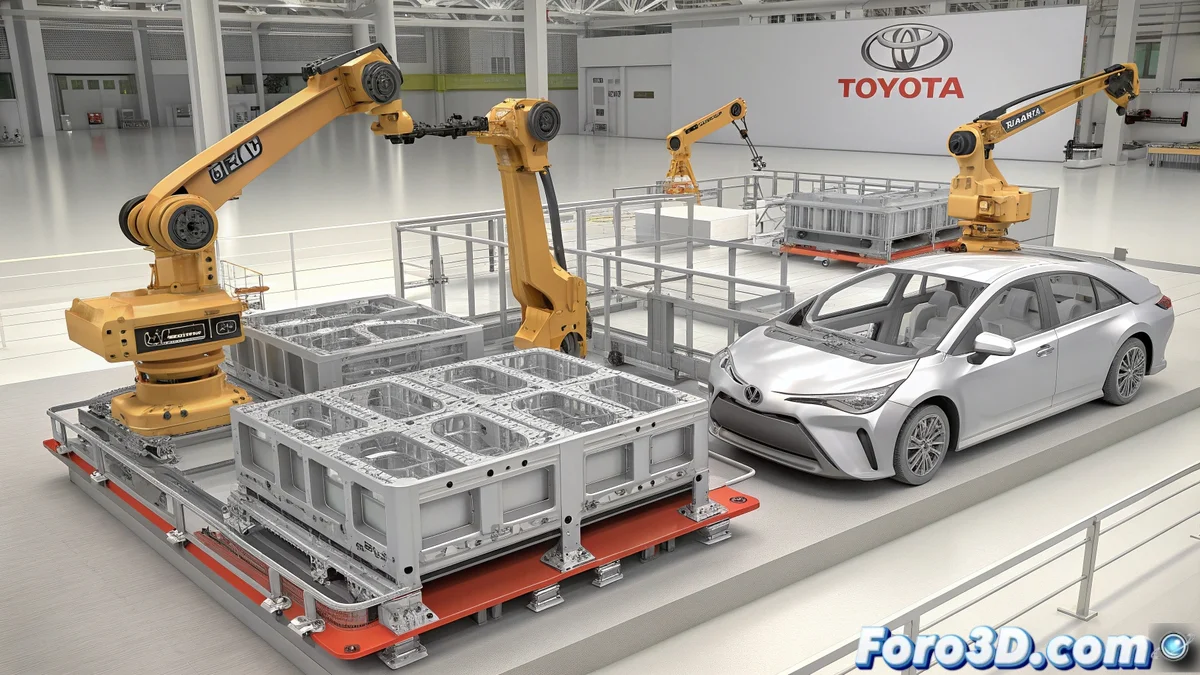

Three giants—Fraunhofer, MacLean-Fogg, and Toyota—have joined forces to develop a large-scale 3D printing system specifically designed for die-casting molds 🚗. This collaboration aims to transform automotive component production, combining cutting-edge research, industrial capability, and innovative vision. The result promises to be a game-changer in how molds are manufactured, with tangible benefits in speed, precision, and adaptability. Because in the automotive world, even molds deserve a luxury upgrade 🔧.

Advantages of 3D Printing in Die Casting

The developed system enables the creation of large molds with intricate geometries that challenge conventional methods. Among its main advantages are cost reduction by minimizing traditional machining, shorter production timelines, and unprecedented flexibility for design adjustments. This not only accelerates prototype manufacturing but also optimizes series production of aluminum components for lighter and more efficient vehicles. Additive precision thus becomes the new quality standard 🏭.

The system enables the creation of large molds with intricate geometries that would be difficult or impossible to manufacture with conventional methods.

Impact on the Industry and Sustainability

Beyond productive efficiency, this project has significant implications for sustainability in the automotive sector. By reducing material and energy waste associated with traditional processes, 3D printing of molds aligns with circular economy and responsible manufacturing goals. Toyota, known for its commitment to green innovation, finds in this technology an ally to produce vehicles that are not only more advanced but also more environmentally friendly. A technological and ecological win-win 🌱.

Key Features of the Printing System

The technology developed by this consortium stands out for several advanced capabilities:

- Complex Geometries: internal and external designs that surpass the limitations of traditional milling or molding.

- High-Performance Materials: metal alloys optimized to withstand high temperatures and pressures.

- Scalability: capability to produce large-sized molds required in the automotive industry.

- Digital Integration: workflows that connect CAD design directly with additive manufacturing.

The Future of Mold Manufacturing is Here

This initiative demonstrates that 3D printing has matured enough to tackle critical industrial applications. It's not just about rapid prototyping, but real large-scale production. For manufacturers like Toyota, it means agility to respond to market demands, and for designers, unprecedented creative freedom. And although the system doesn't print donuts for breakfast, it will undoubtedly manufacture molds at a speed that will leave everyone speechless 🍩.

The Irony of Additive Manufacturing

Now molds are printed faster than it takes someone to decide what color to choose for their new car... although red will always be the fastest, of course 🚦.