Innovation in Metal 3D Printing: Components that Tolerate Imperfections

Metal additive manufacturing is undergoing a radical transformation with the development of systems that allow components to function normally even when they exhibit production irregularities. This approach redefines traditional quality standards 🚀

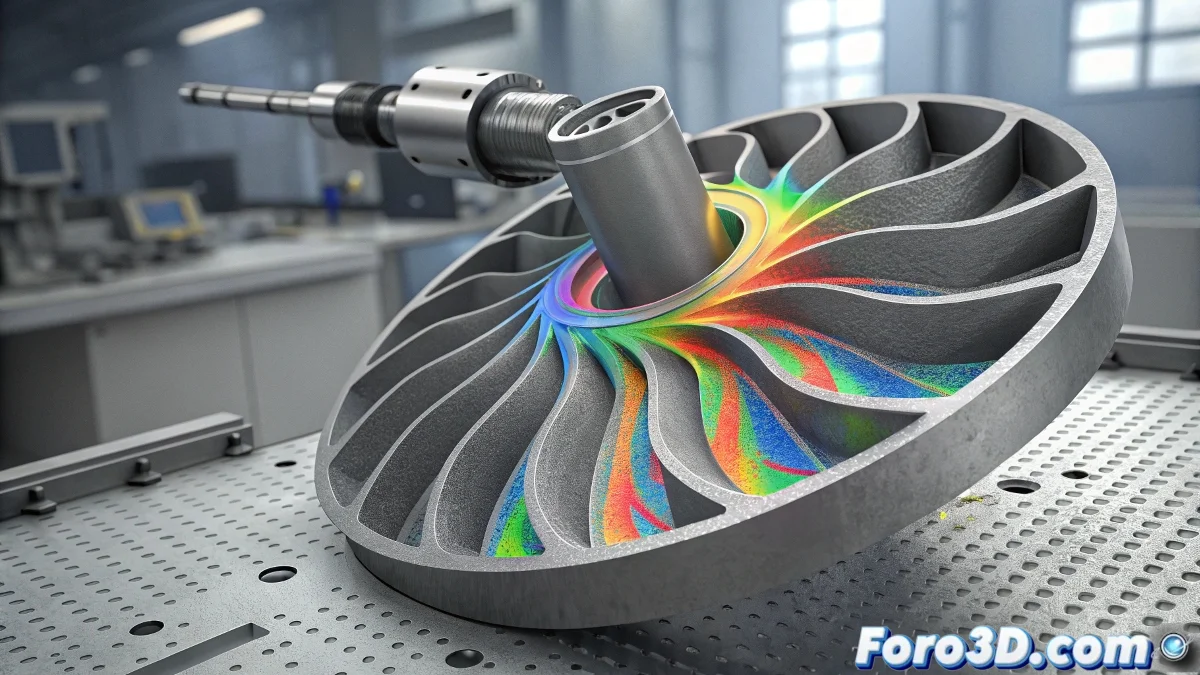

New Structural Design Philosophy

The innovative approach is based on a combination of advanced materials and computational algorithms that anticipate behavior under stress. Researchers have created alloys with self-regulating properties that intelligently manage mechanical loads.

Main Features of the System:- Shape memory metal alloys that adapt to structural stresses

- Topological optimization software that preemptively identifies critical zones

- Predictive models that evaluate the complete lifecycle of the component

We are witnessing a paradigm shift where imperfections cease to be synonymous with failure and become manageable design features

Impact on High-Demand Industries

This technological advancement is particularly relevant in sectors where absolute reliability is non-negotiable. The ability to produce lighter components without sacrificing safety represents a milestone in materials engineering.

Cross-Cutting Benefits:- 40% reduction in quality control and part rejection costs

- Possibility of using more complex and efficient geometries

- Extension of component lifespan in critical environments

Future of Smart Manufacturing

This disruptive technology not only improves structural reliability, but also sets new precedents for Industry 4.0. The integration of artificial intelligence into the design process will enable the creation of components that self-repair during use, paving the way for autonomous and resilient manufacturing 🔧