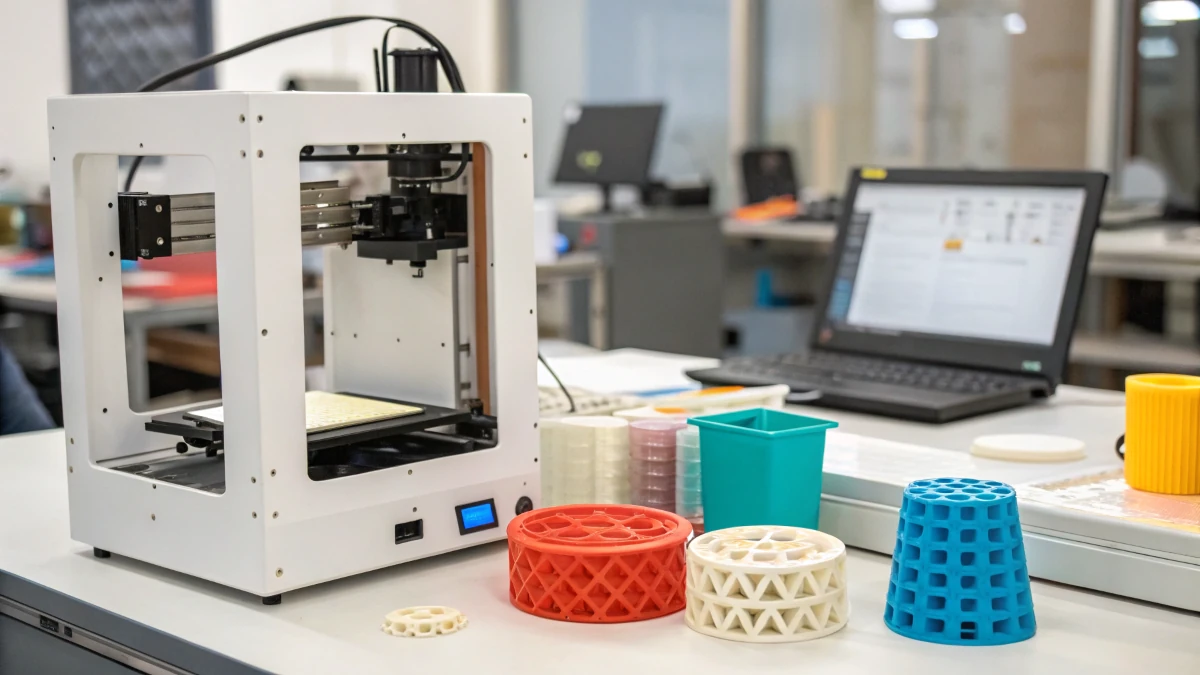

In the competitive world of additive manufacturing, Shapeways has taken a step forward by incorporating fused deposition modeling (FDM) technology into its wide range of services. This innovation, which adds to the seven 3D printing processes already offered by the company, allows Shapeways to meet the needs of an increasingly diverse clientele, from rapid prototypes to end-use parts.

FDM: A Versatile Solution for Manufacturing

FDM technology is known for its ability to create functional and durable parts, making it an ideal option for both industrial and creative applications. According to Jules Witte, Shapeways' COO, this new capability responds to customer demand for cost-effective and efficient solutions. After several months of testing, the FDM service is now available through the company's online quoting tool, facilitating access to this technology.

"Incorporating FDM allows us to offer more versatile solutions, adapting to the specific needs of each client." - Jules Witte, Shapeways.

Materials Available for FDM

Shapeways has launched its FDM service with five main materials, each with unique characteristics that make them ideal for different applications:

- ABS: Resistant and durable, ideal for functional parts.

- ASA: Perfect for outdoor applications due to its UV resistance.

- Polycarbonate: High impact and temperature resistance.

- PET: Recyclable and suitable for food applications.

- PETG: Combines the strength of ABS with the ease of printing of PLA.

Commitment to Quality and Customer Service

Shapeways not only focuses on offering advanced technology but also on ensuring customer satisfaction. The company has a team of experts who advise on material selection and design optimization for FDM printing. This personalized approach ensures that every project meets the highest quality standards.

Benefits for Customers

- Expert advice: Help with material selection and design.

- Guaranteed quality: Functional and durable parts.

- Easy access: Online quoting and simplified processes.

The Renaissance of Shapeways

Shapeways' recent history is a testament to resilience and vision. After facing financial difficulties that led to the bankruptcy of its U.S. division, the company was revitalized last December under the leadership of Marleen Vogelaar (CEO) and Jules Witte (COO). In a recent interview on TCT's Additive Insight podcast, both explained their decision to rescue the brand and their vision to turn Shapeways into the manufacturing engine for other companies.

A Vision for the Future

- Continuous innovation: Expansion of technologies and services.

- Industry support: Boosting growth in various sectors.

- Commitment to excellence: Focus on quality and customer service.

"Our goal is to be the perfect partner for companies looking to make the most of additive manufacturing." - Marleen Vogelaar, Shapeways.

The Future of Additive Manufacturing

With the incorporation of FDM technology and its focus on innovation and customer service, Shapeways is positioned to lead the future of additive manufacturing. The company not only offers technical solutions but also commits to being a strategic partner for its customers, helping them turn their ideas into reality.

Towards a Sustainable Future

- Sustainability: Recyclable materials and efficient processes.

- Collaboration: Working together with customers to achieve optimal results.

- Innovation: Constant development of new technologies and applications.

Shapeways is not only reinventing itself but also redefining what is possible in the world of additive manufacturing. With its focus on quality, versatility, and customer service, the company is ready to face future challenges and remain a benchmark in the industry.