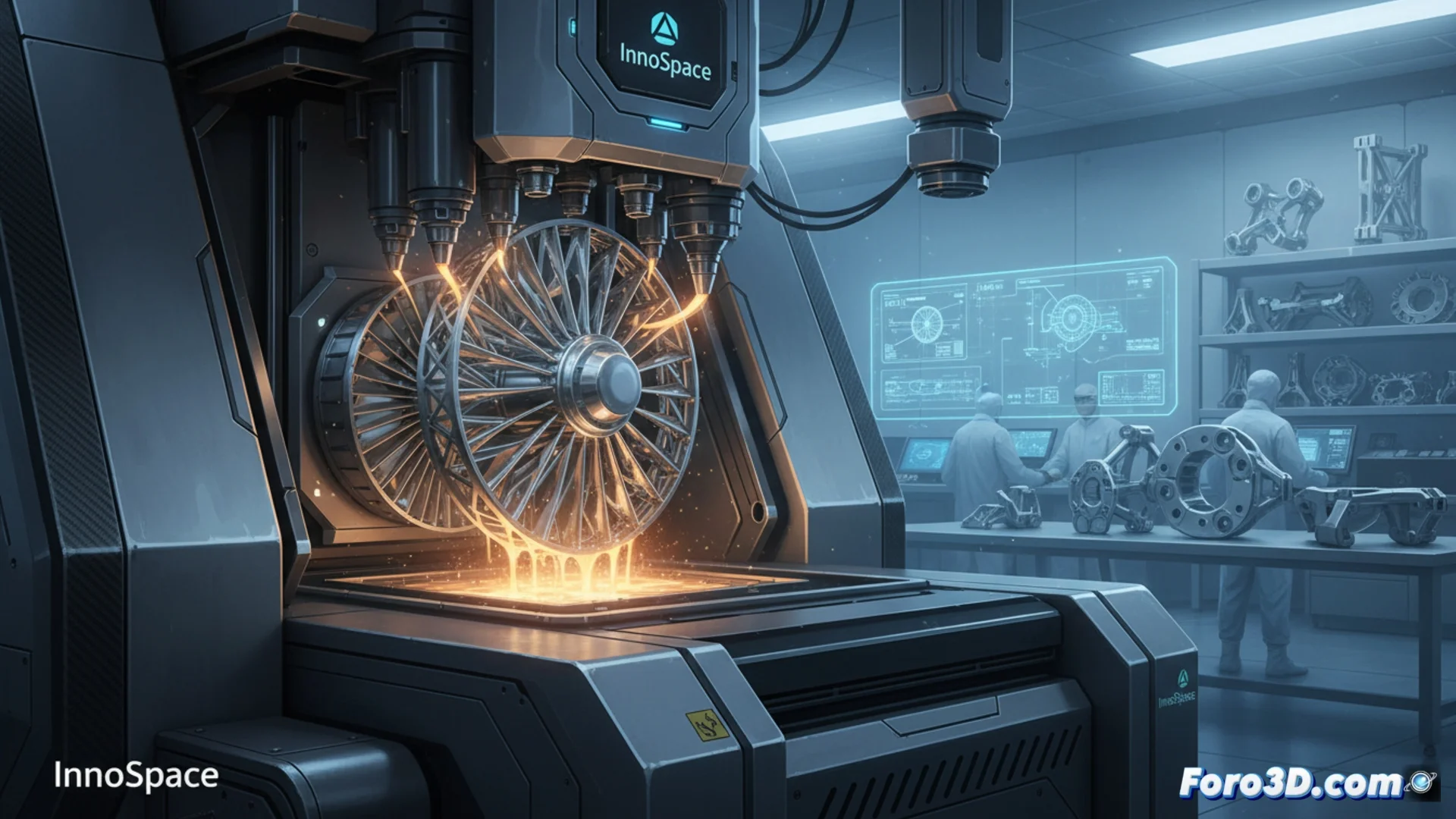

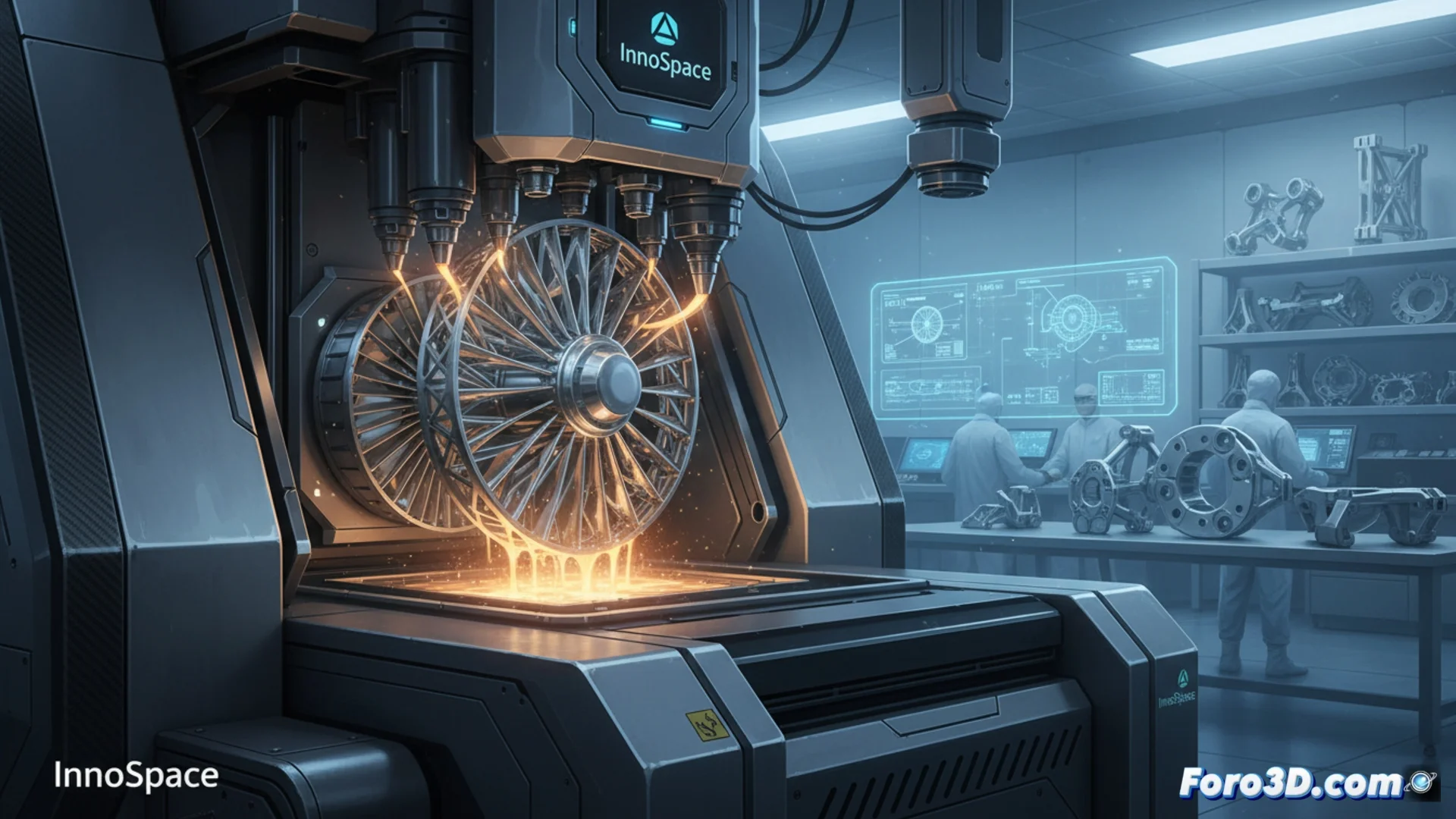

InnoSpace Advances in Support-Free 3D Titanium Printing for the Aerospace Sector

The company InnoSpace has revealed significant progress in the field of additive manufacturing with metals, specifically targeted at titanium for aerospace applications. Its innovation lies in manufacturing components with intricate shapes without requiring the typical support structures, which transforms process efficiency. 🚀

A Process That Saves Material and Simplifies Production

This system employs a high-power laser along with specialized software to melt titanium powder with extreme precision. By avoiding supports, the need to remove them using mechanical or chemical methods is eliminated, which streamlines the manufacturing chain. The result is lighter parts with reduced total costs, two critical factors in space design.

Key Advantages of the Method:- Minimizes wasted titanium material during manufacturing.

- Shortens the time needed for post-printing processing.

- Allows designing and manufacturing complex geometries that were previously prohibitive.

This technology offers a more efficient alternative to conventional methods, such as machining from a solid block, which generates a large amount of waste.

Applications in the Aerospace Sector

The ability to print titanium without supports is crucial for producing elements that demand the highest strength-to-weight ratio. This technique is applicable to a wide spectrum of components within the industry.

Potential Components:- Structural parts for satellites and space probes.

- Internal elements for rocket engines and propulsion.

- Any part requiring titanium's unique durability.

Looking to the Future of Manufacturing

InnoSpace's advancement sets a benchmark for more sustainable and economical manufacturing in a high-demand sector. As this technology consolidates for elite applications, the question arises of when similar principles might trickle down to consumer-grade equipment, where removing supports remains a common challenge. 🔧