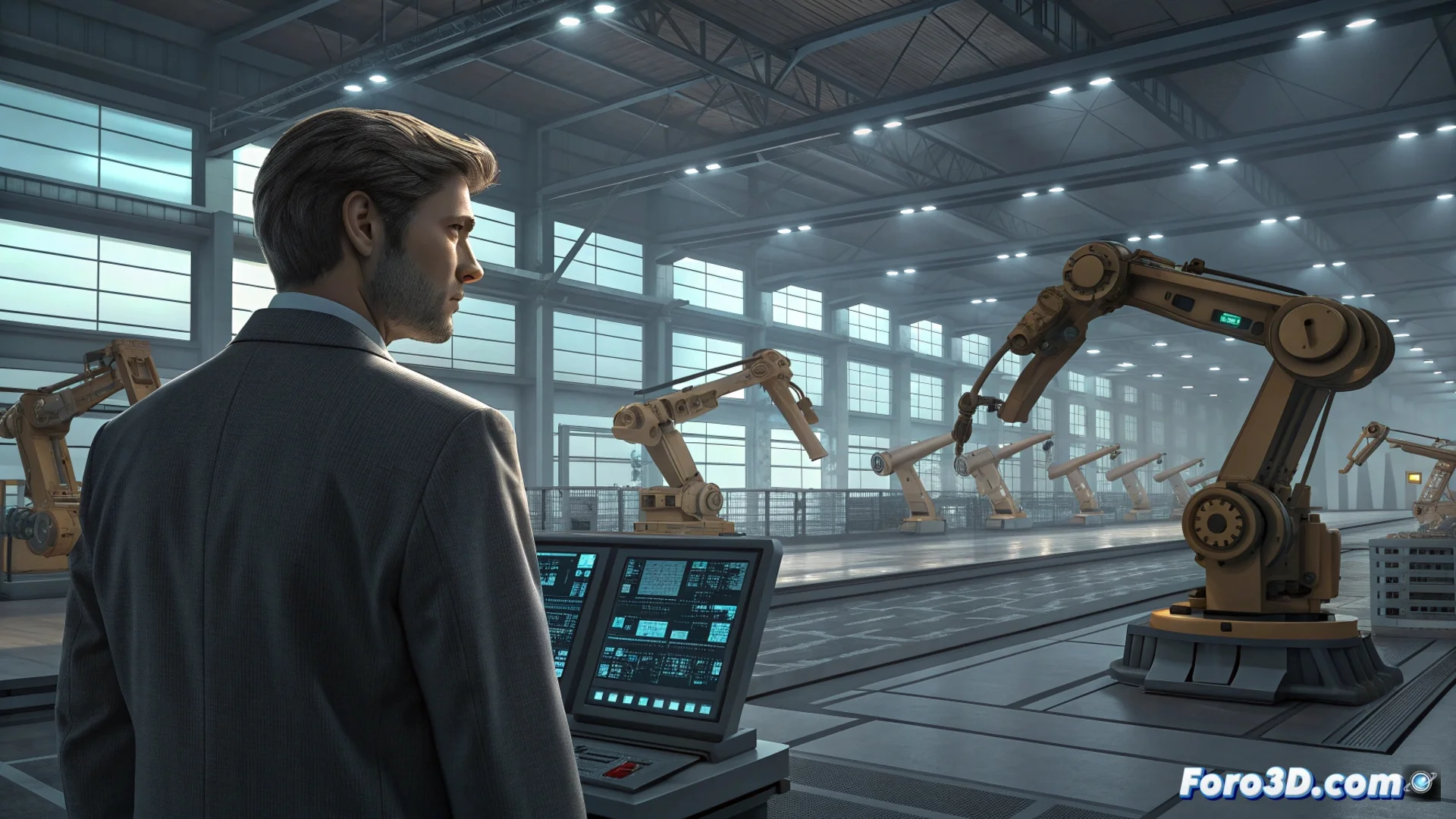

The Industry in 2026: The High Cost of Neglecting Vocational Training

The outlook for the manufacturing sector in 2026 is challenging. A critical shortage of technicians and specialists with the right skills severely limits companies' ability to innovate and expand. This situation is no accident; it is the direct result of having marginalized for years the systems that train technical professionals, while almost exclusively promoting the university path. Now, the bill for that mismatch has arrived, with essential positions remaining vacant. 🏭

The Gap Between What Is Taught and What the Factory Needs

Conventional curricula fail to evolve at the pace imposed by industrial technology. Advances in automation, advanced machinery maintenance, or specialized systems programming render many academic programs obsolete. Companies seek profiles that can operate, repair, and optimize cutting-edge equipment, but training centers often lack access to this technology to provide real-world practice. This disconnect produces graduates who do not meet the experience demanded by the job market.

Direct Consequences of the Disconnect:- New graduates emerge without the practical skills demanded by production lines.

- Companies spend additional months training new employees in basic concepts they should already master.

- Modernization projects and adoption of new technologies are slowed due to a lack of personnel to handle them.

Paradoxically, more resources are now invested in training a single apprentice than were previously allocated to sustain the entire vocational training network.

Companies Take the Reins of Their Future

Faced with the impossibility of finding prepared candidates, the industrial sector is taking matters into its own hands. The trend is clear: internalize training. Numerous organizations have begun designing and implementing their own internal training programs, assuming the cost of training their workforce from a basic level. Another common strategy is to establish close collaborations with the remaining vocational training centers to co-create curricula and ensure students acquire the specific skills the factory requires.

Solutions Companies Are Implementing:- Create corporate academies and introductory courses for specific technical roles.

- Sign partnerships with technical institutes so students can do extensive internships in their facilities.

- Value and promote applied knowledge and manual dexterity above university degrees for certain positions.

A Cycle That Closes with Greater Effort

This movement represents a pragmatic return to valuing hands-on know-how. However, it is a solution that involves higher economic outlay and a slower process than if a robust vocational training network had been maintained. The industry not only must produce, but also fill the gaps in the educational system, dedicating time and capital to a task that is essential for its own survival and competitiveness. The message is clear: neglecting technical training has a price, and in 2026 companies are paying it. ⚙️