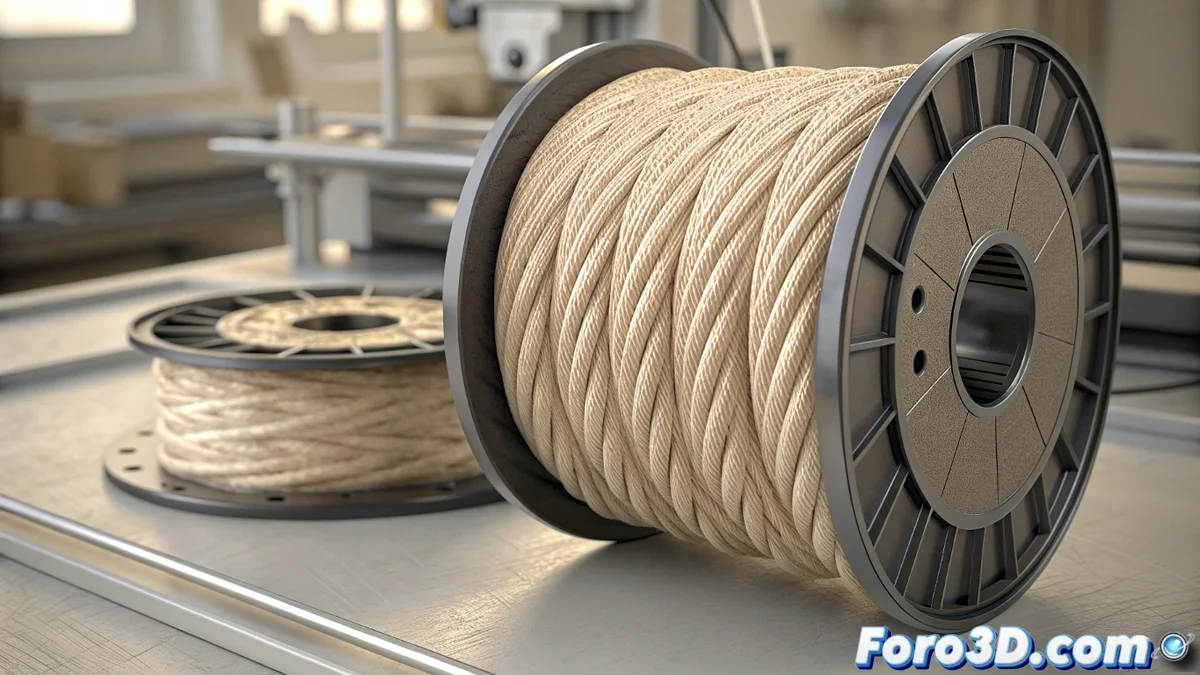

Industrial Hemp as a Natural Reinforcement in 3D Printing

The search for sustainable materials in additive manufacturing is shifting toward renewable resources, and industrial hemp is positioning itself as one of the most promising alternatives. Laboratories are focusing efforts on creating composite filaments that integrate these plant fibers, with the dual objective of enhancing mechanical performance and reducing the environmental impact of manufactured parts. This innovation represents a firm step toward replacing traditional synthetic reinforcements. 🌱

Integration of Natural Fibers: Complexity and Technical Solutions

The incorporation of hemp fibers into polymeric matrices such as PLA or ABS presents considerable technical obstacles. The fundamental challenge is to overcome the incompatibility between the fiber, which attracts water, and the plastic, which repels it, to ensure optimal stress transfer and minimize porosities. The scientific community is addressing this issue through the optimization of surface treatments on the fibers and the precise adjustment of extrusion processing parameters, seeking to achieve a homogeneous and reliable composite for the printing process.

Key Strategies in Filament Development:- Surface Modification of the Fiber: Chemical or physical treatments are applied to improve wettability and interfacial adhesion with the polymeric matrix.

- Extrusion Control: Adjustment of temperature, speed, and mixing to achieve uniform dispersion of the fibers in the filament, avoiding agglomerations.

- Rigorous Characterization: Analysis of morphology, fiber distribution, and mechanical properties of the resulting filament to validate its quality and consistency.

The synergy between natural materials and 3D printing technology is not just a matter of performance, but a commitment to a more planet-friendly production cycle.

Benefits and Emerging Fields of Application

Hemp biocomposites offer tangible advantages: they enable the manufacture of lighter parts with an excellent stiffness-to-weight ratio and a significantly lower carbon footprint. Their potential opens the door to multiple industrial sectors that demand more eco-friendly solutions without sacrificing functionality.

Potential Areas of Use:- Eco-Friendly Prototyping: Creation of models and prototypes with an improved environmental profile for design and ergonomics studies.

- Automotive Components: Manufacturing of non-structural or interior parts, where weight and sustainability are key factors.

- Custom Design and Furniture: On-demand production of decorative elements, lamps, or furniture with a unique natural finish.

Future Outlook and Conclusion

Research into hemp filaments for 3D printing goes beyond mere scientific curiosity; it is a serious line of work with real industrial implications. The possibility of developing materials with controlled biodegradability is especially relevant for single-use or short-life products. Thus, while this plant has its most well-known uses, in the field of additive manufacturing it is demonstrating formidable potential to drive a green revolution in the way we conceive and produce objects. An innovation that combines natural tradition with cutting-edge technology. 🔬