Scientific Revelation on Metallic Particle Bonding

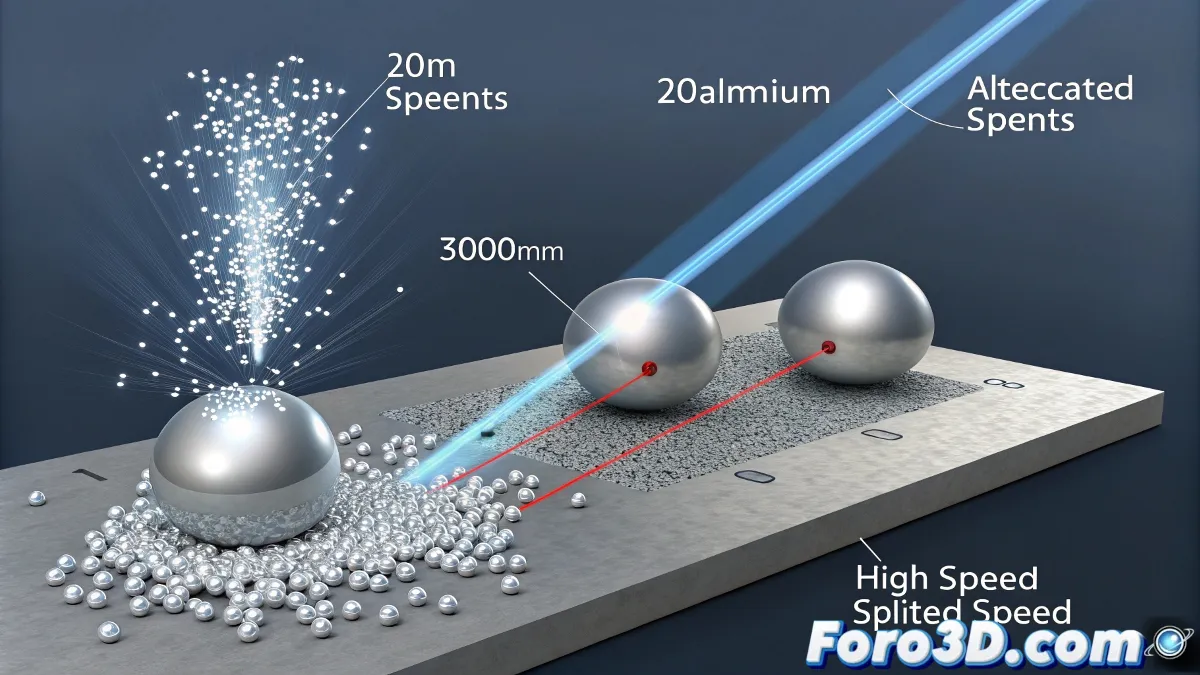

A recent study has changed the understanding of how metals bond at high speeds. The research demonstrated that there is a specific optimal point for achieving maximum adhesion between metallic particles during industrial processes.

Innovative Methodology

The scientific team employed advanced techniques for their research:

- Launch platform: Specialized system for projecting microparticles

- Materials: Micrometer-sized aluminum particles

- Instrumentation: Ultrafast cameras to capture impacts

The results contradict previous assumptions about the linear relationship between speed and bonding quality, explained the lead researchers.

Main Findings

The obtained data revealed crucial information:

| Speed (m/s) | Effect on Bonding |

|---|---|

| 800-1000 | Progressively better adhesion |

| 1060 | Optimal bonding point |

| 1100-1337 | Deterioration of adhesion |

Discovered Mechanism

The observed phenomenon is explained by:

- Energy storage as elastic deformation

- Reduction of beneficial plastic deformation

- Increase in particle rebound

Potential Applications

This knowledge could optimize various industrial processes:

- Metal deposition techniques

- Wear protection systems

- Additive manufacturing processes

- Surface coating technologies

Future Research

The team plans to extend the study to other metallic materials and operating conditions. These findings could lead to significant improvements in the efficiency and quality of various industrial processes.