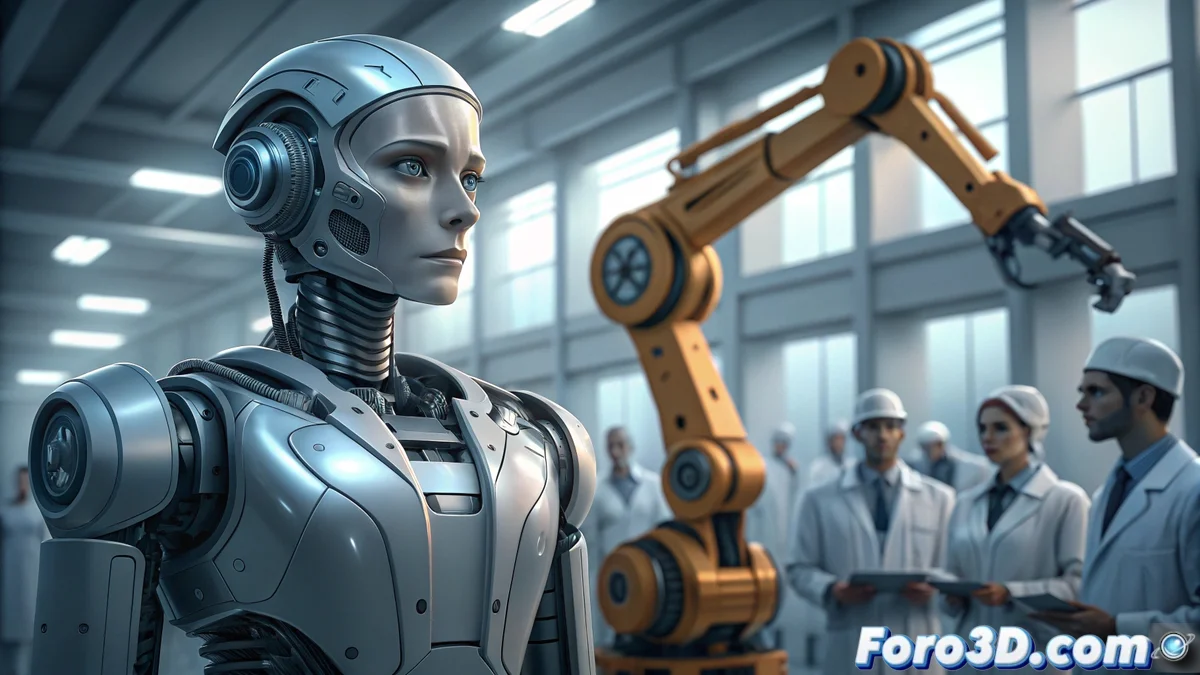

Humanoid Robots in Factories: A Divided Vision of the Future

The debate on industrial automation intensifies with the arrival of humanoid robots. While some specialists prefer traditional systems, others, like the director of the technology holding Arm, see in these machines the next leap for producing in factories. 🤖

Arm's Bet on Robotic Versatility

Arm's central argument is based on flexibility. Unlike current specialized machines, a robot with a human form can learn and execute various functions. This avoids redesigning the entire production chain when needing to change what is manufactured or respond to new demand. Its ability to program multiple tasks is its main advantage.

Key advantages according to this vision:- Adapt production lines more quickly.

- Reconfigure processes without massive investments in new hardware.

- Learn different operations, increasing versatility.

"These systems will be entrusted with a significant part of the work in factories within five or ten years." - Arm Director.

The Skeptical Stance of Traditional Automators

Those who have been automating industrial processes for years question this idea. For them, systems dedicated to a specific task are faster, more precise, and reliable in high-repetition environments. Introducing a complex robot that imitates human anatomy and has a high cost may not be the most efficient way to optimize productivity and profitability.

Arguments of skepticism:- Specialized systems execute repetitive tasks with greater speed and precision.

- Reliability is a critical factor where stopping the line is very costly.

- The cost-benefit ratio of a humanoid versus a dedicated machine is not clear.

A Future Yet to Be Defined

The conflict between specialized efficiency and versatile adaptability marks the path. While engineers debate these technical and economic aspects, technology advances. Perhaps the real challenge is not just to produce, but to create machines that can integrate seamlessly and, who knows, even grab a coffee on a break without causing a disaster. ⚙️