Material strength against fractures is a crucial aspect in multiple industries, from tire manufacturing to biomedicine. Recently, researchers have identified a universal law that allows predicting how materials based on flexible networks break, opening new opportunities to optimize their durability.

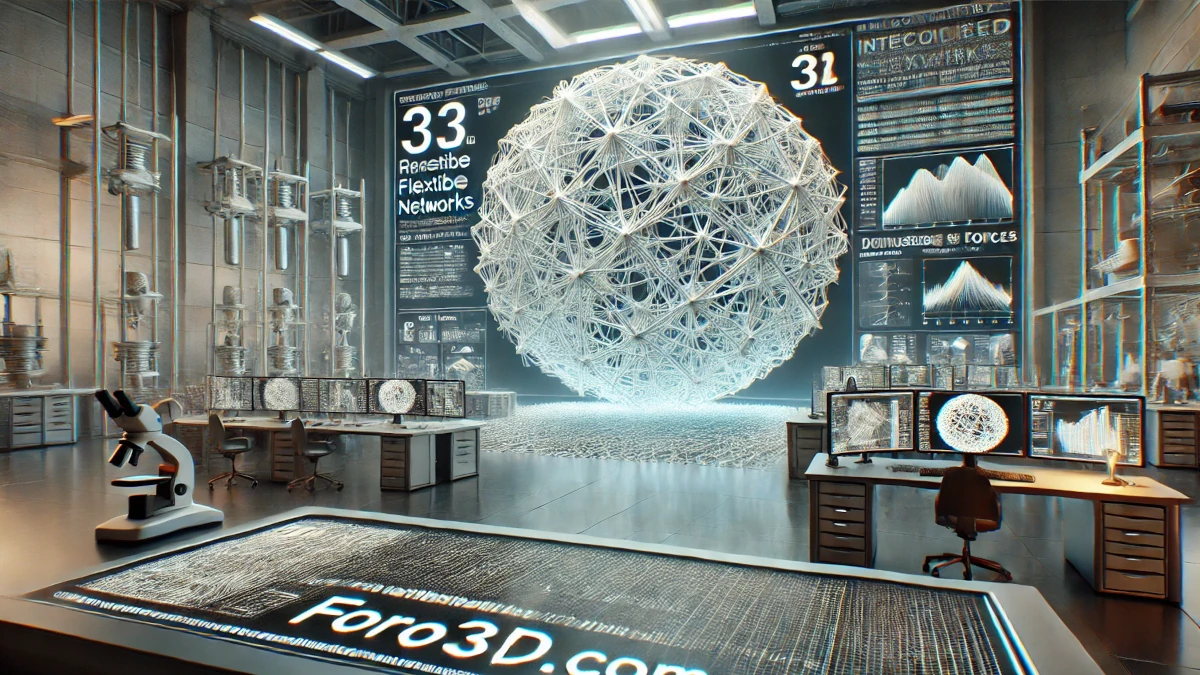

The Behavior of Flexible Networks

Materials composed of interconnected filament networks have demonstrated remarkable strength. The key to their durability lies in the interaction of these filaments, which can redistribute forces and avoid immediate fracture.

Factors Influencing Strength

- Filament length: The longer the filaments, the greater their ability to absorb energy without breaking.

- Stretch capacity: Materials with greater elasticity can withstand more deformations before fracturing.

- Structural reinforcement: An optimized network design can improve resistance to external forces.

Applications in Engineering and Robotics

These principles can be applied in various fields of engineering and robotics. Some examples include:

- Design of components for soft robotics: Flexible materials that mimic natural structures.

- Advanced artificial tissues: Development of biomedical materials with greater durability.

- High-performance structures: Creation of materials with optimized strength for demanding environments.

"Understanding how flexible networks resist fracture is key to designing more efficient and safe materials in the future."

The Future of Materials Engineering

Thanks to these discoveries, material manufacturing takes a step forward in creating more resistant and adaptable structures. With a greater understanding of fracture mechanics, it is possible to design safer, lighter, and more durable materials that could revolutionize multiple industries in the coming years.