How to Fix Error E05 on Bamboo Printers

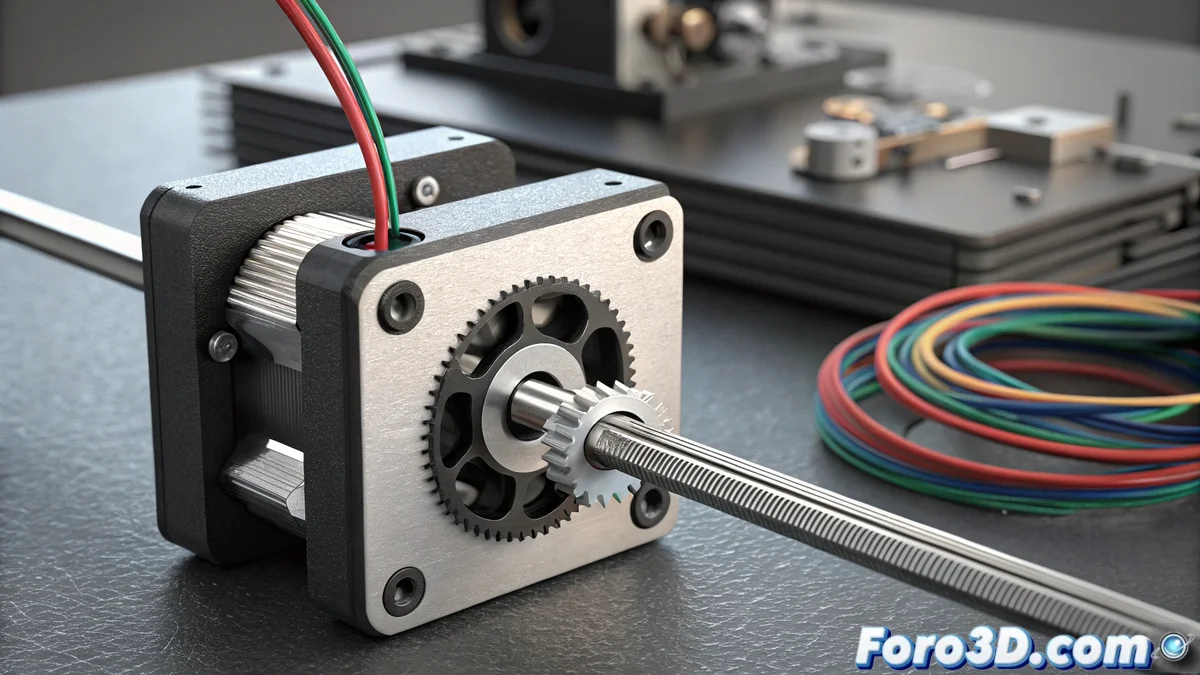

When your Bamboo printer displays the E05 code, it is alerting about possible failures in the motion system. This error is generally triggered during the homing process or axis movement, when the machine detects discrepancies between the expected and actual movement. As a protective measure, the printer stops automatically to avoid major damage to its mechanical components 🔧.

Complete Problem Diagnosis

To identify the origin of the E05 error, begin by performing a visual inspection of all connection cables associated with the stepper motor and endstop sensors. Disconnect and reconnect each connector, ensuring they are properly inserted. Then, manually move the carriage and hotend base to verify they slide without obstructions. If you perceive resistance to movement, it could indicate worn bearings or overly tensioned belts that overload the motor.

Initial Verification Steps:- Visual review of electrical connections and cable condition

- Manual movement test to detect mechanical obstructions

- Evaluation of belt tension and axis lubrication

A well-maintained printer is like a Swiss watch: precise and reliable. Prevention avoids 80% of common errors.

Detailed Solution Procedure

Start the corrective process by thoroughly cleaning all rails and axes with isopropyl alcohol, then applying specific lubricant for 3D printers. If the problem persists, try swapping the stepper motor cables with another functional axis to rule out faults in the electrical wiring. To check the endstop sensors, manually activate each one while monitoring its response on the control panel. If any sensor does not react properly, you will need to proceed with its replacement. In cases where the motor has irreparable faults, contact authorized technical service for professional repair or replacement.

Corrective Action Sequence:- Deep cleaning of mechanical components with isopropyl alcohol

- Cable swapping to rule out electrical faults

- Individual sensor testing and replacement if necessary

Important Final Considerations

Modern 3D printers have such sensitive detection systems that they can identify minimal issues like slightly loose cables or dust buildup on the rails. Although this extreme caution may seem excessive, it effectively prevents your prints from turning into unwanted abstract sculptures. Maintaining a regular maintenance protocol is the key to avoiding recurrence of the E05 error and ensuring consistent quality prints 🎯.