In a world where technology advances by leaps and bounds, metal 3D printing has become a key tool for innovation in manufacturing. Honda, the Japanese automotive giant, has adopted this technology to transform various fields of mobility, from automobiles and motorcycles to energy products and aeronautics. With additive manufacturing, Honda not only seeks to reduce costs and production times but also to improve the quality and customization of its products.

Cost Reduction and Quality Improvement

One of Honda's main objectives in implementing metal 3D printing is to optimize its manufacturing processes. This technology allows for the creation of stronger and lighter components, which not only improves product performance but also reduces costs associated with traditional manufacturing methods. In a promotional blog and video, the company highlighted how additive manufacturing is revolutionizing its production approach.

"Metal 3D printing allows us to create more efficient and customized parts, while at the same time reducing production times and costs." - Honda.

Benefits of 3D Printing at Honda

- Cost reduction: Lower spending on materials and processes.

- Quality improvement: More resistant and lightweight parts.

- Customization: Designs adapted to specific needs.

3D Printing in Formula 1: A Success Story

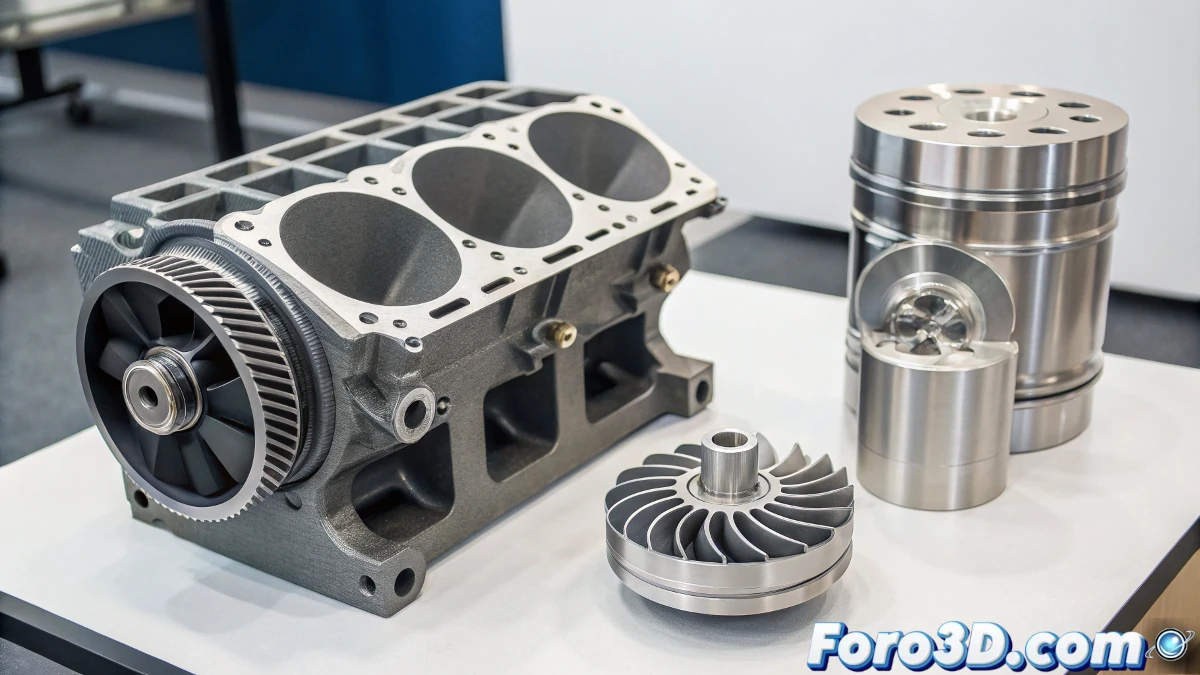

One of the most outstanding examples of Honda's use of metal 3D printing is its application in Formula 1. In 2020, the company used this technology to manufacture pistons and turbine housings for race car engines. These components, made of iron and Inconel (a heat-resistant material), not only helped the Red Bull team achieve victory but also significantly reduced production times and costs.

Innovations in F1

- Iron pistons: Lighter and more resistant than aluminum ones.

- Turbine housings: Made of Inconel to withstand high temperatures.

- Efficiency: Reduction in costs and production times.

3D Printing to Improve Quality of Life

Honda has not only applied metal 3D printing in the world of motorsport but also in the creation of products for people with specific needs. A notable example is the lightweight aluminum handlebars designed for racing wheelchairs. Using topological optimization software, Honda's engineers were able to create customized handlebars that improve grip, safety, and reduce unnecessary weight.

Benefits for People with Disabilities

- Customization: Designs adapted to individual needs.

- Safety: Improvement in ergonomics and grip.

- Weight reduction: Greater comfort and efficiency.

The Future of Additive Manufacturing at Honda

Honda's growing interest in metal 3D printing reflects a significant shift in the manufacturing industry. This technology's ability to create complex and customized parts without the long waiting times associated with traditional methods is revolutionizing the way components are produced. With the support of deformation prediction simulations and rigorous testing, Honda continues to refine its additive manufacturing capabilities.

Towards a More Innovative Future

- Research and development: Investment in new technologies.

- Process optimization: Use of advanced simulations and tests.

- Expansion of applications: From automobiles to energy products.

"Metal 3D printing is not just a manufacturing tool; it is a gateway to a more efficient and personalized future."

With each advancement in metal 3D printing, Honda is redefining what is possible in modern manufacturing, taking innovation to new levels and improving the quality of life for people around the world.