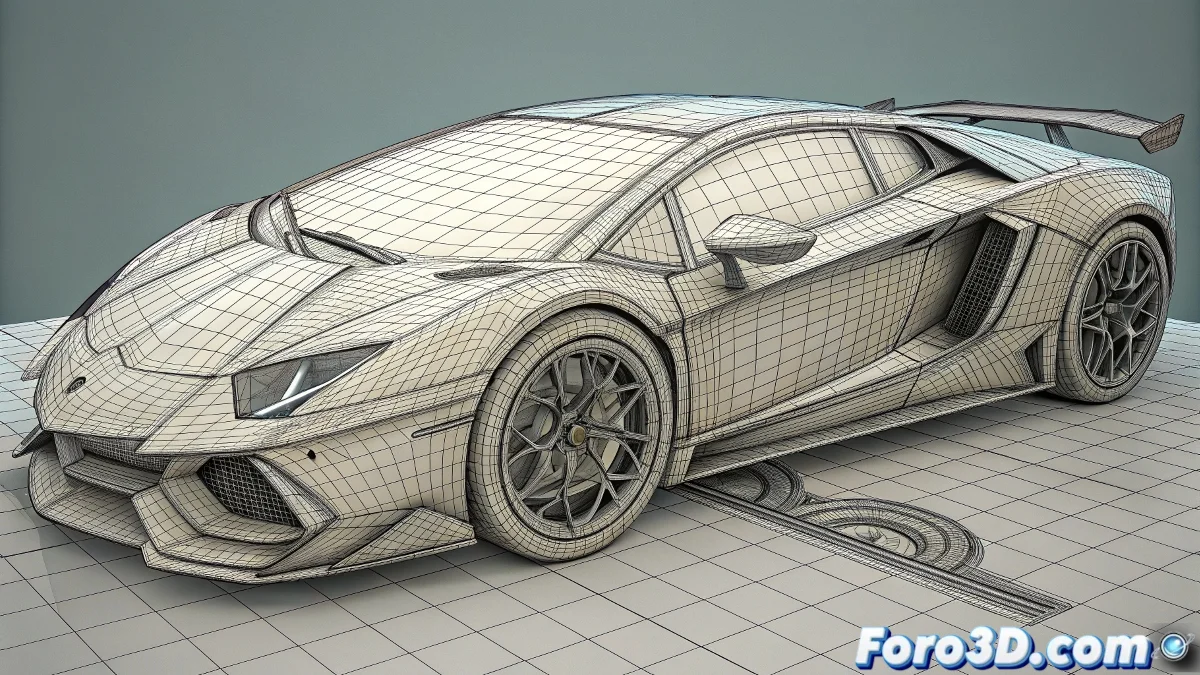

3D Printing Accelerates in the World of Motorsports

The Graham Rahal Performance team has turbocharged their manufacturing processes by incorporating industrial 3D printing to create critical high-performance components. Using a Markforged printer, they have produced exhaust system parts for a competition Lamborghini, demonstrating that additive manufacturing has reached the maturity needed for the most demanding environments. A qualitative leap that redefines the limits of digital manufacturing in the world of motorsports.

Beyond Rapid Prototyping

What makes this application special is the use of advanced composite materials that withstand extreme conditions. The Markforged printer uses carbon fibers and special metals capable of resisting the extremely high temperatures and constant vibrations of a competition exhaust system. These are not decorative parts but functional components that must perform at their maximum under constant pressure, marking a before and after in the perception of 3D printing applied to motorsports.

Competitive Advantages on the Track

- Significant weight reduction in critical components

- Capability for optimized internal geometries impossible to machine

- Radically shorter development and manufacturing times

- Extreme customization according to specific conditions of each circuit

Why It Makes a Difference

While early 3D printers were limited to plastic prototypes, current technology allows for the creation of end-use parts with superior mechanical properties. The ability to print with continuous carbon fiber reinforcement provides a strength-to-weight ratio that directly competes with traditional alloys. A technological evolution that is transforming the manufacturing of high-performance components across various industries.

Practical Applications in Competition

- Rapid iteration of designs based on telemetry data

- On-demand manufacturing of spare parts

- Aerodynamic optimization through complex geometries

- Inventory reduction through just-in-time manufacturing

A practical demonstration of how additive manufacturing has evolved from rapid prototyping to the production of critical components for maximum performance.

For competition teams, this technology means being able to react faster to the challenges of each race, manufacturing optimized components in hours instead of weeks. The gained agility could make the difference between stepping onto the podium or not 🏆.

And all this while traditional mechanics are still looking for that wrench they left somewhere... because with 3D printing, if you lose a part, you just print it again. Although the wrench could probably be printed too, to be consistent with the concept 😅.