Hennessey Revolutionizes Venom F5 Thermal Management with 3D Printing

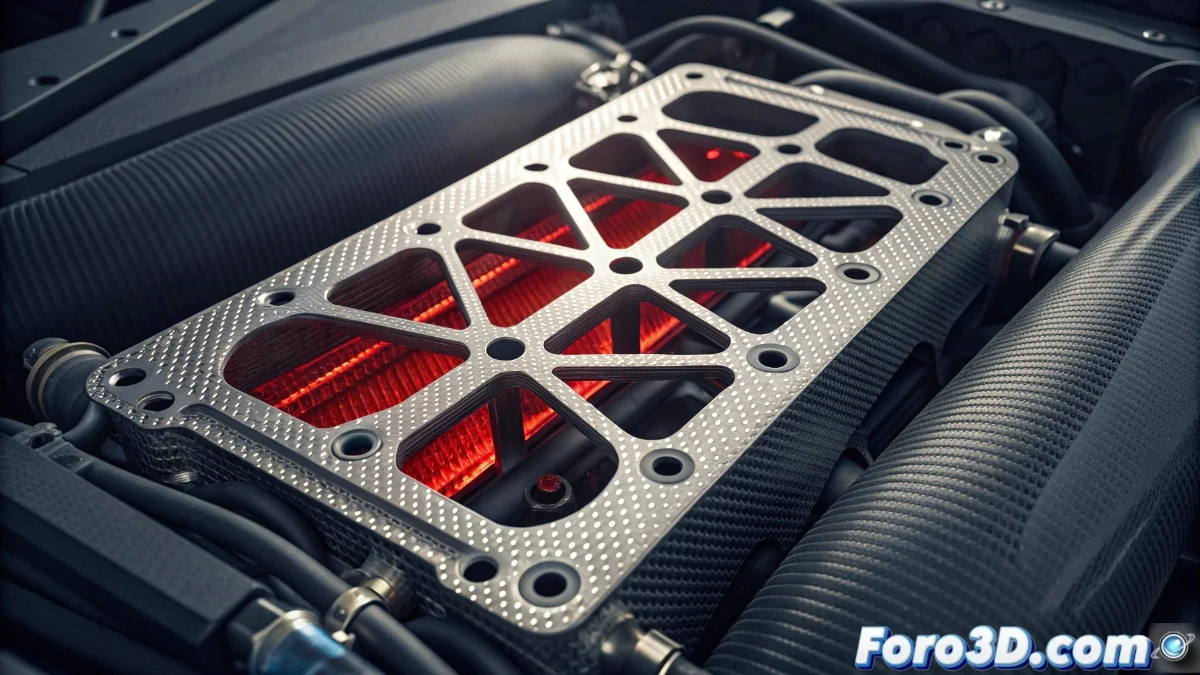

The hypercar manufacturer Hennessey is radically transforming the thermal management approach in its iconic Venom F5 model through the strategic implementation of 3D printing technology for essential components. This innovation enables the production of titanium and aluminum cooling systems with internal configurations that would be impossible to manufacture using conventional techniques, dramatically optimizing airflow and heat dissipation in a powertrain exceeding 1800 horsepower 🔥

Advanced Geometries for Maximum Thermal Efficiency

The components manufactured using additive manufacturing include elements of the cooling system and air management mechanisms that face extreme thermal conditions during vehicle operation. The ability to create internal structures with intricate cooling channels and expanded heat exchange surfaces is fundamental for maintaining controlled temperatures in an ultra-high-performance combustion engine, where every degree Celsius directly impacts maximum performance 🚗

Key features of the printed components:- Internal geometries with cooling channels impossible to achieve with traditional methods

- Significantly expanded heat exchange surfaces for greater dissipation

- Premium materials like titanium and aluminum optimized for thermal resistance

"When your engine generates enough heat to melt conventional metals, you can't settle for basic cooling solutions" - Hennessey Engineering Philosophy

Competitive Advantages in Hypercar Manufacturing

This technological approach not only improves thermal performance but also contributes to weight reduction of components and significantly accelerates development cycles. Hennessey can rapidly iterate on the design of these critical parts, experimenting with different internal configurations until achieving the perfect optimization for airflow and heat dissipation demanded by a vehicle built to break world speed records ⚡

Main benefits of implementation:- Significant reduction in the total weight of cooling system components

- Drastic acceleration of development and prototype validation processes

- Extreme customization capability in internal geometries for thermal optimization

The Future of Thermal Management in Automotive

The implementation of 3D printing in critical Venom F5 components establishes a new paradigm in automotive thermal engineering, demonstrating how advanced manufacturing technologies can solve challenges that previously seemed insurmountable. This approach not only benefits the vehicle's immediate performance but also lays the foundation for future innovations in the hypercar industry and beyond 🏎️