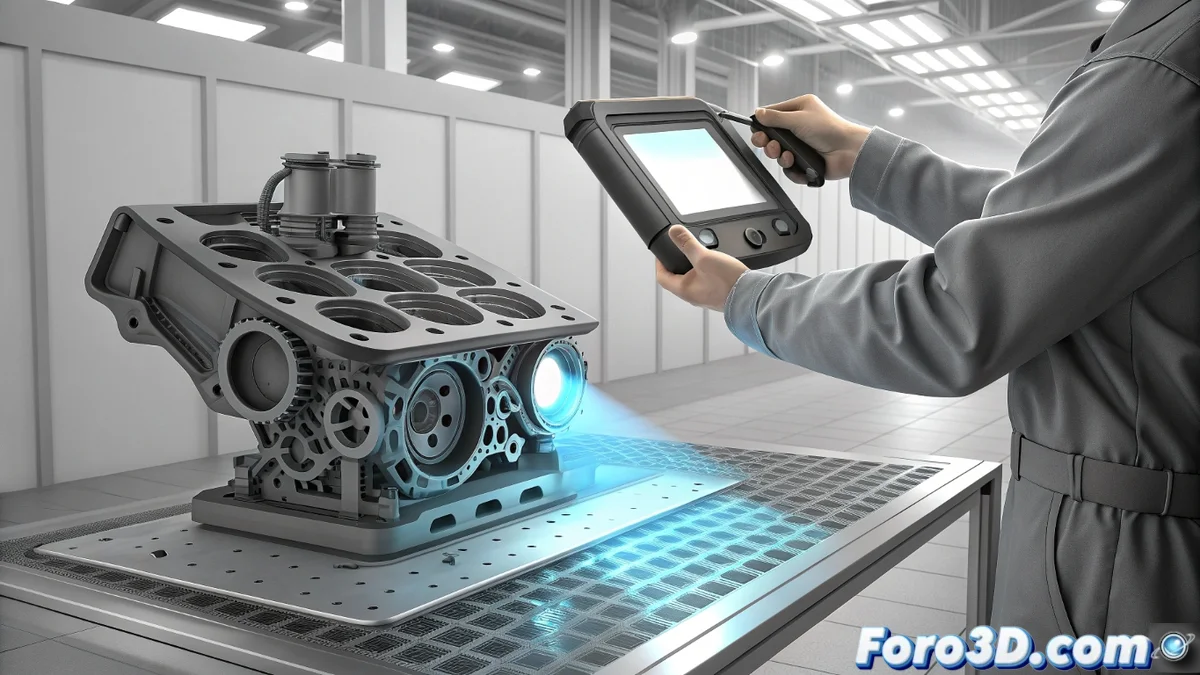

Handheld 3D Scanner Artec Leo: Autonomy and Precision in 3D Capture

Three-dimensional digitization takes a leap toward complete independence with devices like the Artec Leo. This handheld scanner redefines portability by integrating the entire system needed to capture real-world objects, without ties to external workstations. Its one-handed operation and immediate visualization on the touchscreen make it a highly agile tool for multiple professional sectors. 🚀

Technical Architecture and Independent Operation

The key to the Artec Leo lies in its design as an autonomous scanning station. It incorporates a processing unit, long-lasting battery, and internal storage, eliminating the need for cables and laptops during capture. Its structured light technology projects a safe pattern onto the object, while multiple cameras record the geometry and color in great detail. The onboard software performs alignment and registration in real time, displaying a dense and textured point cloud that allows instant coverage verification.

Key Components of Its Autonomy:- Integrated Processor and Software: Performs initial frame processing directly on the device.

- Color Touchscreen: Facilitates visualization and navigation of the 3D model during the scanning session.

- Battery and Internal Storage: Enables prolonged field sessions without interruptions.

The ability to see the 3D model grow on the screen while scanning transforms the process, allowing immediate corrections and ensuring complete capture.

Workflow and Industrial Applications

The process begins with on-site capture, where the user guides the scanner around the object. The data is then transferred to Artec Studio software on a computer for advanced post-processing, including scan fusion, cleaning, and generation of CAD- or 3D printing-ready meshes. This combination of field speed and office precision makes it ideal for reverse engineering, quality control, and heritage documentation.

Main Operational Advantages:- Ergonomics and Speed: Digitizes medium-sized objects, such as industrial parts or sculptures, with great speed.

- Submillimeter Precision: Suitable for applications requiring high dimensional and texture fidelity.

- Operation in Complex Locations: Its portability simplifies work in hard-to-reach spaces.

Practical Considerations and Scope of Use

Although it is a powerful tool, it has certain limitations. Very shiny, dark surfaces or extremely complex geometries may require the use of anti-reflective spray or a more meticulous scanning strategy. Its positioning in the professional range is reflected in its price, targeting it as an investment for studios, companies, and institutions where digitization efficiency directly impacts productivity. It is not a device for hobbyists, but a solution for projects where time and precision are critical. 💼