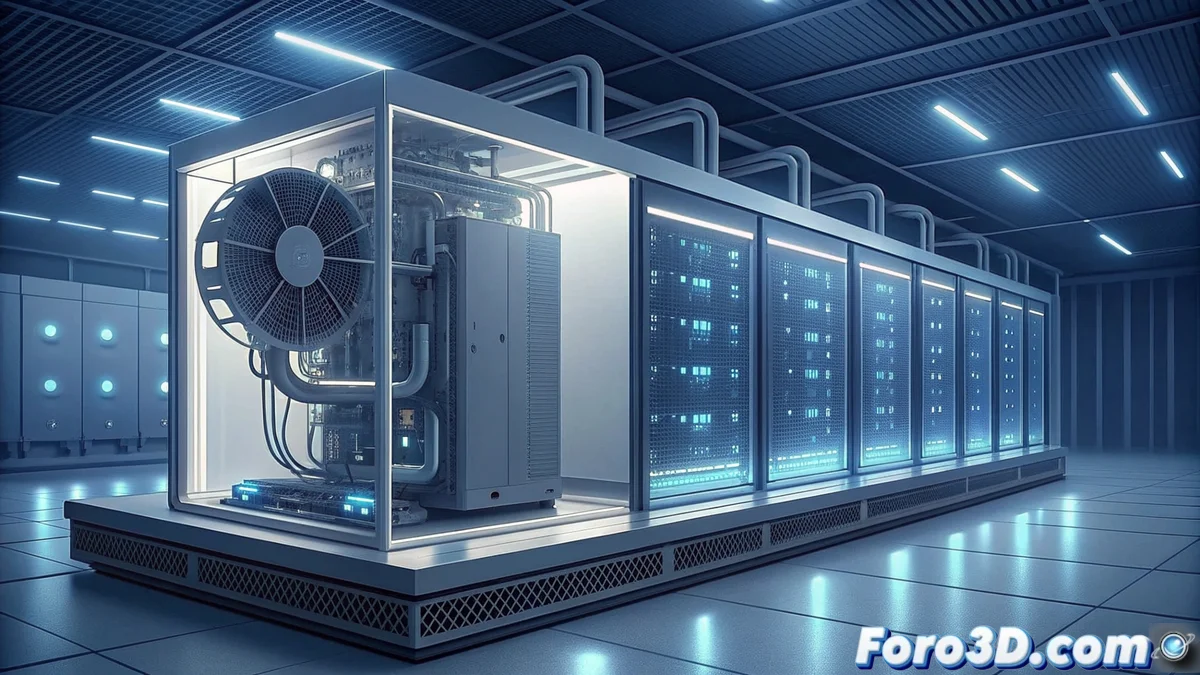

Haier Presents Magnetic Levitation Cooling for Data Centers

During the twentieth edition of the annual Chinese data center industry event, Haier Smart Building unveiled a key innovation: its magnetic levitation cooling system. This technology is presented as a direct response to the growing challenges faced by high-performance computing facilities, often called supercomputing engines, due to the intense heat generated by AI and autonomous driving chips. 🚀

The Thermal Challenge of Modern Computing

Today's data centers operate under unprecedented thermal pressure. Chips that run complex artificial intelligence algorithms and autonomous systems work at extreme speeds, producing massive amounts of heat. Conventional cooling systems, which rely on mixed air and liquid methods, struggle to adapt to such specific and variable demands for each component, in addition to having to meet increasingly strict energy efficiency standards. This mismatch represents a considerable technical and economic obstacle.

Limitations of traditional methods:- Difficulty responding to different temperature requirements for each individual chip.

- Complexity in optimally balancing air and liquid cooling.

- Constant challenge to meet energy efficiency standards (PUE) without compromising performance.

The real bottleneck for artificial intelligence is not just processing data, but preventing servers from melting while doing so.

Haier's Proposal: Frictionless Efficiency

Haier's solution is based on technology with over two decades of development. The core principle of its magnetic levitation system is to eliminate physical contact in key components. This translates into two fundamental operational advantages: oil-free and frictionless operation. The absence of friction not only reduces energy consumption during continuous operation but also prevents performance degradation over time, a common problem in traditional compressors.

Key advantages of magnetic technology:- Frictionless operation: Reduces mechanical wear and maintains high efficiency throughout the equipment's lifespan.

- Oil-free operation: Eliminates the need for lubricants, simplifying maintenance and improving reliability.

- Reduce long-term costs: Less need for repairs and part replacements, crucial for infrastructures that require uninterrupted operation (uptime).

Impact on Critical Infrastructure

The implementation of this technology has profound implications for the industry. By optimizing heat dissipation more efficiently and reliably, data centers can house more powerful hardware, necessary to advance fields like machine learning and large-scale simulation. Beyond immediate energy savings, the substantial reduction in planned and unplanned maintenance tasks strengthens the resilience of these facilities, which are the backbone of the digital economy. Haier's innovation points to a path where thermal management ceases to be a limit and becomes an enabler for the next wave of computational advances. ⚙️