Green Ammonia Fuel Cells: Clean Energy for a Sustainable Future

In the search for decarbonized energy solutions, green ammonia fuel cells emerge strongly as a revolutionary alternative. This system not only enables direct and clean electricity generation, but also solves one of the great challenges of renewables: large-scale and long-term storage. Its potential to transform industrial sectors and heavy transport is immense. ⚡

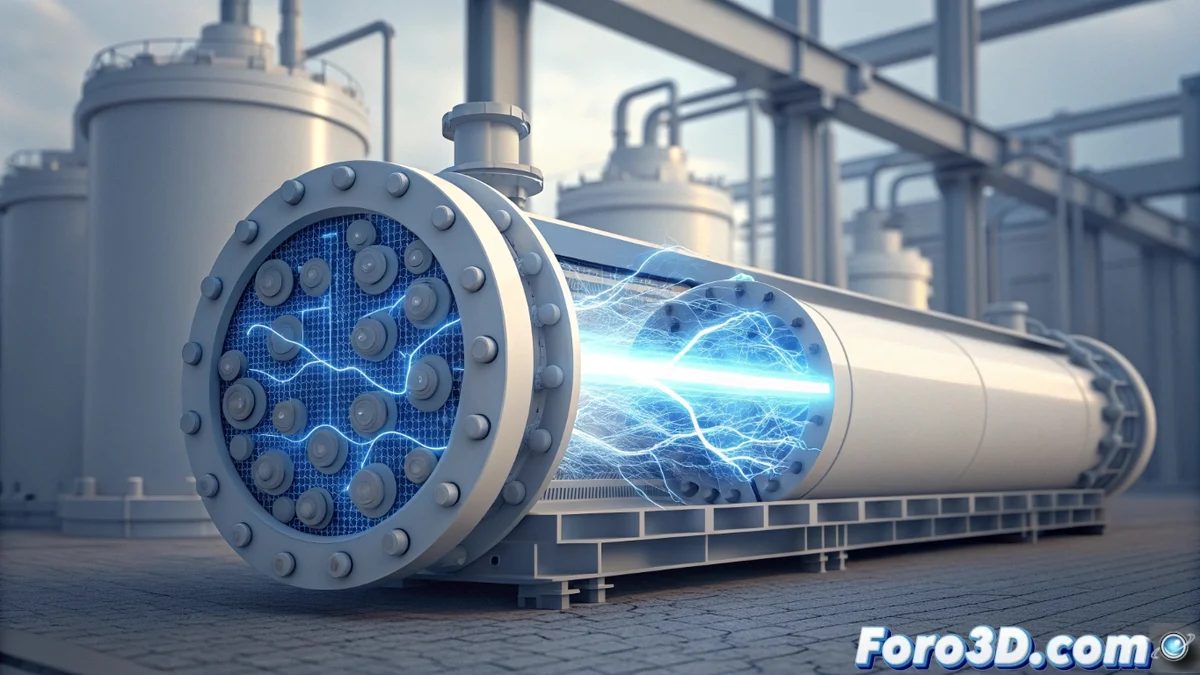

The Mechanism of an Energy Revolution

The operating principle is as elegant as it is efficient. The technology is based on the catalytic decomposition of ammonia (NH3), previously synthesized using solar or wind energy, within the cell itself. This process releases hydrogen that immediately feeds an electrochemical reaction, producing electrical energy. The only byproducts are atmospheric nitrogen and water vapor, making the process a source of energy completely free of carbon emissions during its use.

Key advantages as an energy vector:- High energy density: Ammonia stores more energy per volume than compressed hydrogen, facilitating its logistics.

- Existing infrastructure: It can be transported and stored using the global network already developed for the fertilizer industry.

- Stability and safety: It is easier and safer to handle under environmental conditions than other alternatives like liquid hydrogen.

"Green ammonia is not just a hydrogen carrier; it is an energy vector in its own right, with the capacity to decarbonize the global economy." - Energy sector analysis.

Technological Advances and Pending Challenges

Current research focuses on overcoming technical and economic obstacles. The development of more efficient and affordable catalysts, which do not depend on precious metals like ruthenium, is crucial to reduce costs. In parallel, membranes and cell architecture are being optimized to improve power density and durability, addressing the inherently slow reaction kinetics of ammonia.

Main challenges for its mass implementation:- Production cost: The manufacturing of green ammonia through processes like Haber-Bosch powered by renewables still requires significant investments to be competitive.

- Process purity: It is essential to ensure that nitrogen oxides (NOx) are not generated and that the cells are tolerant to impurities.

- Industrial scaling: Taking the manufacturing of these cells from the laboratory to a commercial scale that competes with other clean technologies.

A Future Powered by Basic Chemistry

The irony that a compound commonly associated with fertilizers and cleaners could become the fuel of the future for container ships or industrial plants is powerful. Green ammonia fuel cells symbolize a pragmatic convergence between known chemistry and radical innovation. They do not seek an exotic "holy grail," but a practical, storable, and transportable solution that could fertilize a new clean and resilient energy landscape. 🌱➡️🚢