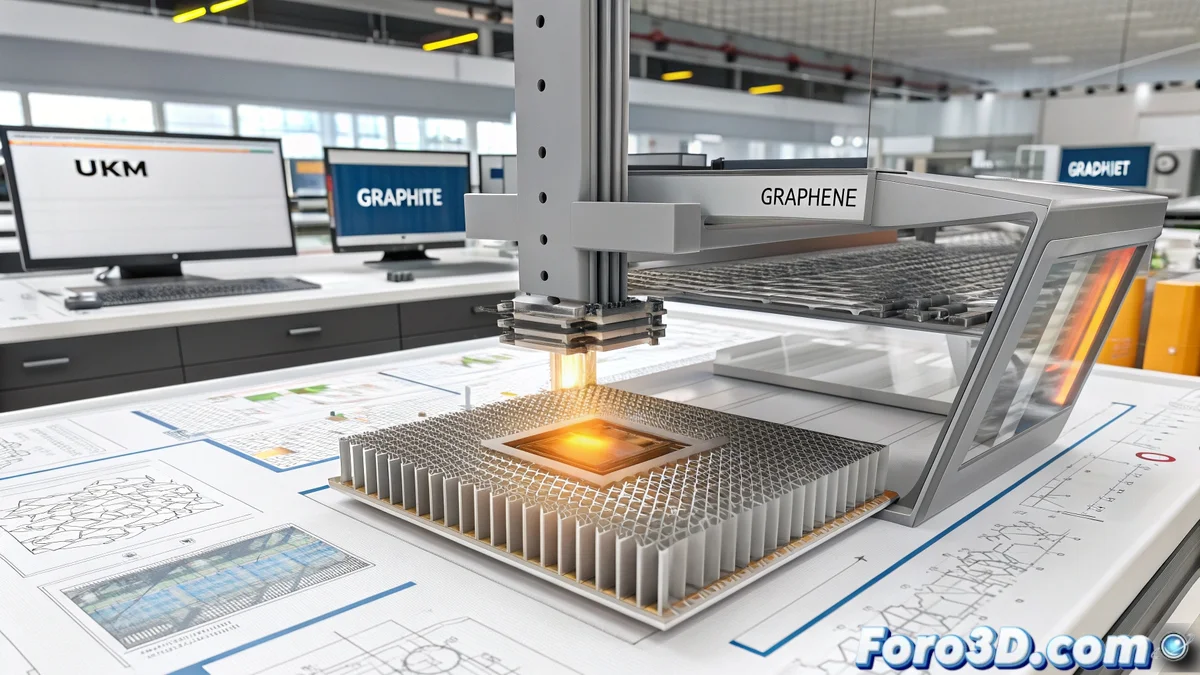

Thermal Innovation from Malaysia: Graphene Meets Additive Manufacturing

Graphjet Technology, a Malaysian pioneer in graphite and graphene from palm shells, joins the Centre for Materials and Intelligent Manufacturing Engineering (MERCU) at Universiti Kebangsaan Malaysia (UKM) 🌴. They have received a letter of intent under the Ministry of Higher Education Malaysia's Consortium of Research Excellence 2025 program, to develop advanced heat sinks using additive manufacturing with graphite and graphene. This alliance represents the forefront in cooling solutions for the accelerated computing era.

Strategic Drivers of the Collaboration

The project addresses critical needs in the technology market:

- AI Chip Demand: Specialized processors require efficient cooling

- Thermal Customization: Additive manufacturing enables optimized heat sinks

- Energy Efficiency: Reduction in data center consumption

- Advanced Materials: Graphene offers superior thermal conductivity

- Sustainability: Graphene derived from agricultural waste

- Development Speed: In-house lab accelerates research

These factors converge at a critical moment for global technological infrastructure ⚡.

Advantages of the Technical Approach

The combination of technologies offers unique benefits:

- Complex Geometries: Optimized internal structures impossible to manufacture traditionally

- Superior Conductivity: Graphene provides exceptional thermal performance

- Customization: Heat sinks tailored to specific chip needs

- Weight Reduction: Advanced materials enable lighter designs

- Scalability: Additive manufacturing facilitates production at different scales

- Sustainability: Use of renewable resources (palm shells)

These advantages are crucial for the next generation of electronics 🌀.

Regional Context and Market Opportunities

Malaysia is strategically positioned in the technology ecosystem:

- Investment in Data Centers: AWS, Microsoft, Google, Alibaba, Equinix, NTT

- Developing Infrastructure: Accelerated growth in data center capacity

- Geographical Location: Ideal positioning for regional services

- Government Support: Research and technological development programs

- Academic Ecosystem: Collaboration between industry and universities

- Export Opportunity: Thermal technology for global markets

This environment creates ideal conditions for innovation and commercialization 🌏.

They're working on futuristic 3D heat sinks with recycled graphene... while you struggle because your Blender model crashes during rendering

In the end, this project demonstrates how the most advanced technology is often built on unexpected traditional foundations. While Graphjet transforms palm shells into AI cooling solutions, it reminds us that real innovation can come from any source... although their thermal heat sink renders are probably more stable than our Blender projects 😅.