From Human Fat to 3D Bioprinting: The Evolution of Tides

The company Tides has taken a significant turn since its beginnings. Founded in 2009, it initially focused on distributing products based on placental tissue. Today, its main focus is developing an advanced platform for regenerative medicine. Its core innovation consists of using 3D printing with a special bio-ink derived from human fat to treat complex wounds that the body cannot heal on its own. 🔬

The Raw Material: Donated Adipose Tissue

The process begins with human adipose tissue donated by people. This material undergoes a rigorous protocol to extract and process its extracellular matrix. The result is a decellularized biomaterial, rich in essential components like collagen and various growth factors. This substance becomes the fundamental bio-ink for printing.

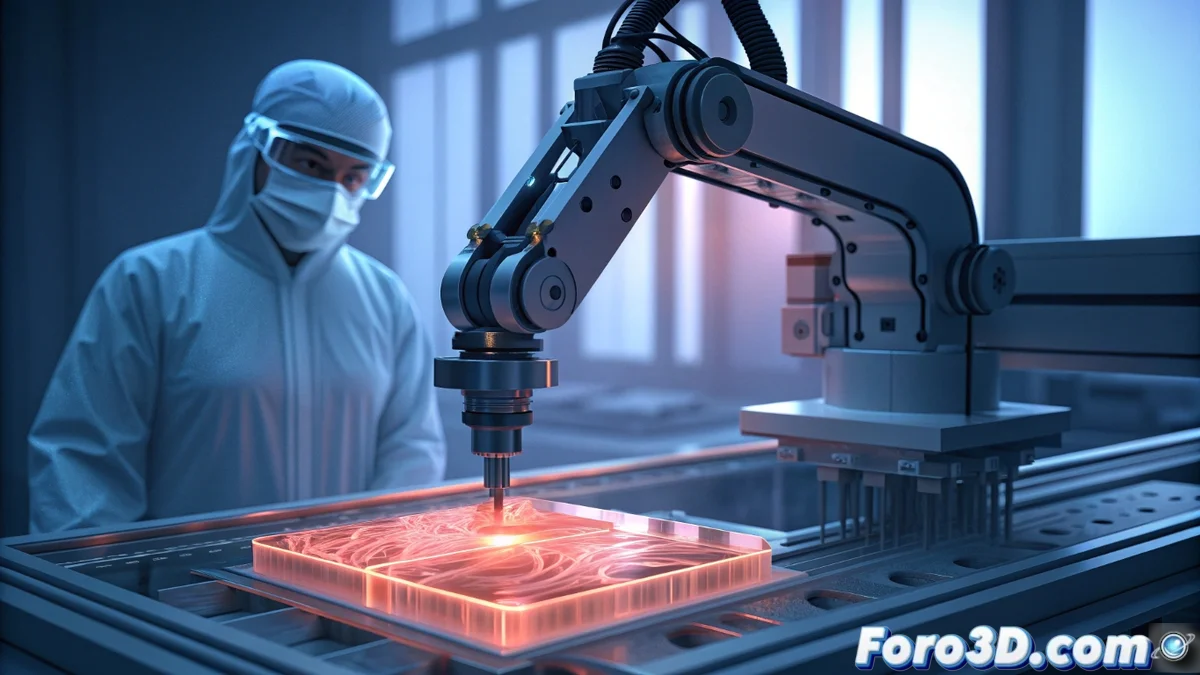

Implant Manufacturing Process:- The 3D bioprinter deposits layers of the biomaterial gel precisely.

- This gel is combined with live cells extracted from the patient themselves.

- The result is a customized scaffold or patch that adapts to the specific wound.

The bio-printed implant acts as a temporary structure that the body can colonize.

Activating Natural Tissue Regeneration

The goal of the bio-printed patch is not just to cover the wound. It functions as a temporary biological scaffold that provides biochemical signals and 3D physical support. This environment guides the patient's cells to repair the damaged tissue effectively. The technology aims to solve complex medical problems where healing mechanisms fail, such as in diabetic ulcers. Currently, the project is in a preclinical research and development phase. 🧪

Advantages of the Approach:- Uses a biological material native to the body, reducing the risk of rejection.

- Customization allows the implant to adapt to the exact geometry of the injury.

- Seeks to activate the body's intrinsic healing processes.

A New Use for Adipose Tissue

This development poses an innovative perspective. Adipose tissue, often associated only with aesthetic problems, finds a high-value application in the field of biofabrication. Its redemption would not be in storing energy, but in becoming the living ink for a 3D printer in a laboratory, opening paths for personalized regenerative treatments that are more effective. 💡