Friction: the essential force that keeps the world in place

Imagine a world where every step was a slip, where cars couldn't stop and tools slipped from your hands. This would be reality without friction, that resistance generated when two surfaces contact and try to move relative to each other. It is an omnipresent force that, far from being an obstacle, enables control and motion transmission in our daily lives and technology. 🔧

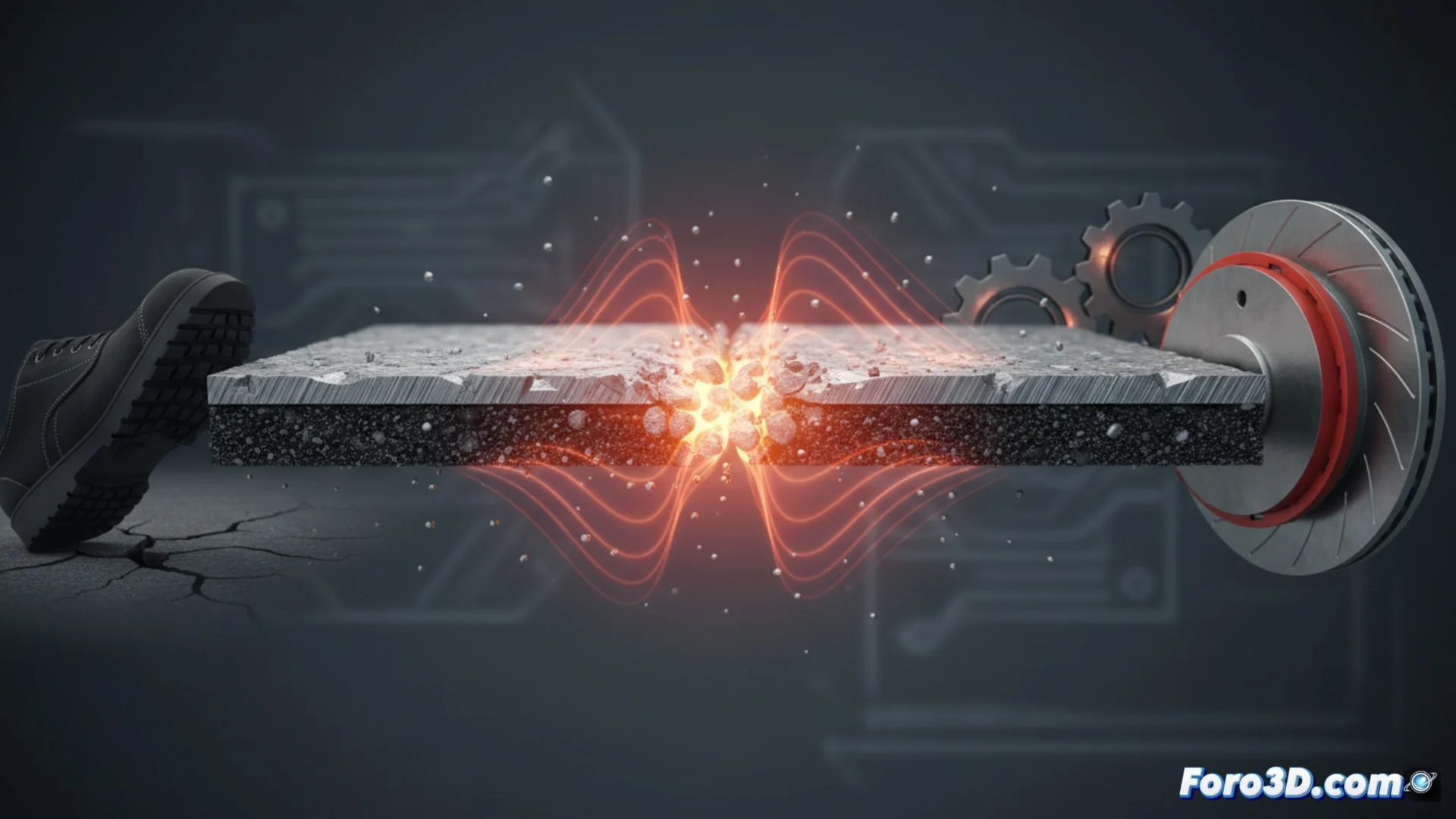

The two faces of friction: static and kinetic

This fundamental force manifests primarily in two ways. Static friction acts to prevent an object from starting to move, like the one that keeps a tire firmly adhered to the pavement to propel a car. On the other hand, kinetic friction (or dynamic) is the one that opposes existing motion, being the main responsible for braking. In the design of any mechanical system, from a simple screw to an advanced engine, calculating and leveraging these types of friction is a critical step. Its intensity can be modified by altering the surface materials, applying lubricants, or using special coatings.

Everyday actions impossible without friction:- Walking or running: Footwear grips the ground thanks to static friction; without it, we would slip without advancing.

- Braking a vehicle: Brake pads pressing on the disc generate kinetic friction, transforming motion energy into heat to stop the wheels.

- Using tools: A hammer or screwdriver is held in the hand due to friction, allowing precise force application.

Without friction, not only would it be impossible to stop a car, but also to start it without its wheels spinning idly on the pavement.

Managing friction in engineering and design

In the technological and industrial field, managing friction is a constant balance. On one hand, it is indispensable for key functions: it allows clutches to transmit power, transmission belts not to slip, and materials to be held during manufacturing processes. On the other hand, its collateral effects are significant: it causes wear in components, generates unwanted heat, and dissipates energy, reducing the overall efficiency of machines.

Strategies to control friction:- Material selection: Choosing combinations with specific friction coefficients for each application (e.g., metal-ceramic for brakes).

- Lubrication: Introducing oils or greases to create a layer that separates surfaces and minimizes direct contact and wear.

- Surface treatments: Applying hard coatings or polishing surfaces to alter their friction properties.

A force with a double effect

Therefore, friction is not simply "bad" or "good." It is a force with a double edge. Its meticulous study and control are fundamental to optimize performance, improve durability, and ensure the safety of virtually all mechanical devices around us. Engineers and designers constantly seek to maximize its beneficial effects where grip and transmission are needed, and minimize its harmful consequences where it causes losses and deterioration. Mastering this balance is what allows the mechanical world to function reliably and efficiently. ⚙️