Tests and Advances in Additive Manufacturing

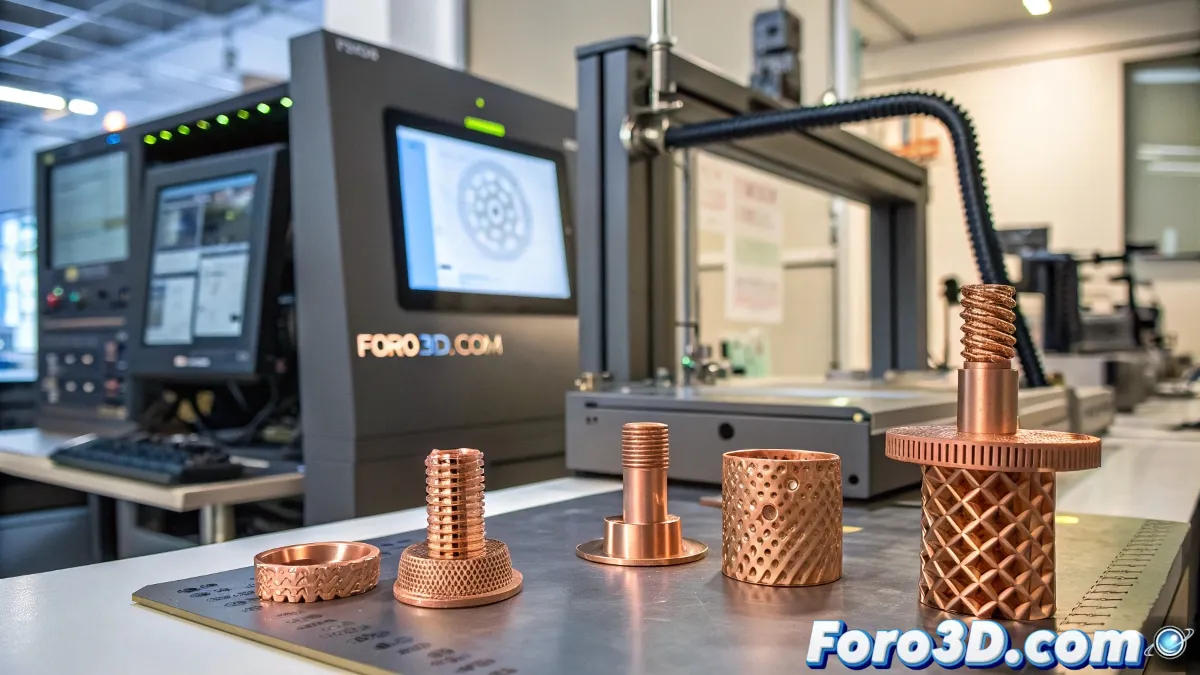

The Swedish 3D printing company, Freemelt AB, has received a new order from the defense manufacturer Saab to produce copper components intended for testing. This order comes after a successful initial study aimed at validating the use of copper materials in additive manufacturing processes. The collaboration between both companies marks an important step in exploring new technologies for defense applications.

Strategic Collaboration for the Future

The next phase of the project focuses on conducting application tests with the manufactured components. This step is crucial to determine if the process can advance to a proof-of-concept phase, which would open the door to larger-scale production in the defense sector. The methodical approach of Saab and Freemelt reflects the importance of ensuring the reliability and effectiveness of the components before their final implementation.

"The advancement to the next phase of the study is a clear confirmation of the value that Freemelt's technology brings to the manufacturing of critical components." - Daniel Gidlund, CEO of Freemelt

A Step Forward in Defense Technology

The relationship between Freemelt and Saab is not limited to this project. Both companies, along with Saab Dynamics and Linköping University, are involved in an initiative funded by Vinnova, Sweden's innovation agency. This parallel project aims to establish additive manufacturing as a reliable production method for advanced applications in the defense sector.

Integration of 3D Printing in the Defense Industry

Daniel Gidlund, CEO of Freemelt, expressed his enthusiasm for this collaboration, highlighting that the advancement to the next phase of the study is a clear confirmation of the value that Freemelt's technology brings to the manufacturing of critical components. This partnership not only strengthens Freemelt's position in the market but also underscores Saab's commitment to innovation and continuous improvement in its production processes.

- Innovation: Use of copper in additive manufacturing for defense applications.

- Collaboration: Joint project between Freemelt, Saab, and Linköping University.

- Testing: Application testing phase to validate the feasibility of the components.

The project between Freemelt and Saab is an example of how additive manufacturing is gaining ground in highly specialized sectors, such as defense. The methodical progression of the study, from initial feasibility to application testing, demonstrates a careful and rigorous approach to ensure that the technology meets the demanding standards of the industry. This advancement not only benefits the involved companies but also lays the foundation for future innovations in the field of strategic component manufacturing.