The Gateway to Flexibility

Flexible PLA represents the ideal starting point for those who want to explore the world of elastic materials without immediately facing the challenges of TPU or TPE. This filament offers smooth and controlled flexibility while maintaining the ease of printing of traditional PLA, acting as a perfect bridge between rigid materials and highly elastic ones. Its predictable behavior makes it the perfect choice for first experiments with parts that require a certain degree of deformation.

What makes Flexible PLA special is its ability to bend without breaking while maintaining the familiarity of PLA. Unlike advanced flexible materials that can be complicated for basic printers, this filament behaves similarly to standard PLA in terms of temperature and adhesion, but with that additional flexibility quality that opens up new design possibilities. It is the perfect material for learning the basics of flexible printing without the steep learning curve.

Properties of Controlled Flexibility

- Moderate flexibility ideal for applications requiring some elasticity

- Printing behavior similar to standard PLA with minor adjustments

- Improved impact resistance compared to rigid PLA

- Ability to recover its shape after moderate deformations

Mastering Basic Flexible Printing

Working with Flexible PLA requires small adjustments compared to conventional PLA. Printing temperatures are usually slightly lower, generally between 185°C and 210°C, to prevent the material from becoming too fluid. Print speed should be reduced to 30-40 mm/s, and retractions should be set conservatively to avoid feeding issues. Unlike advanced flexibles, this material can work acceptably in Bowden systems with the proper setup.

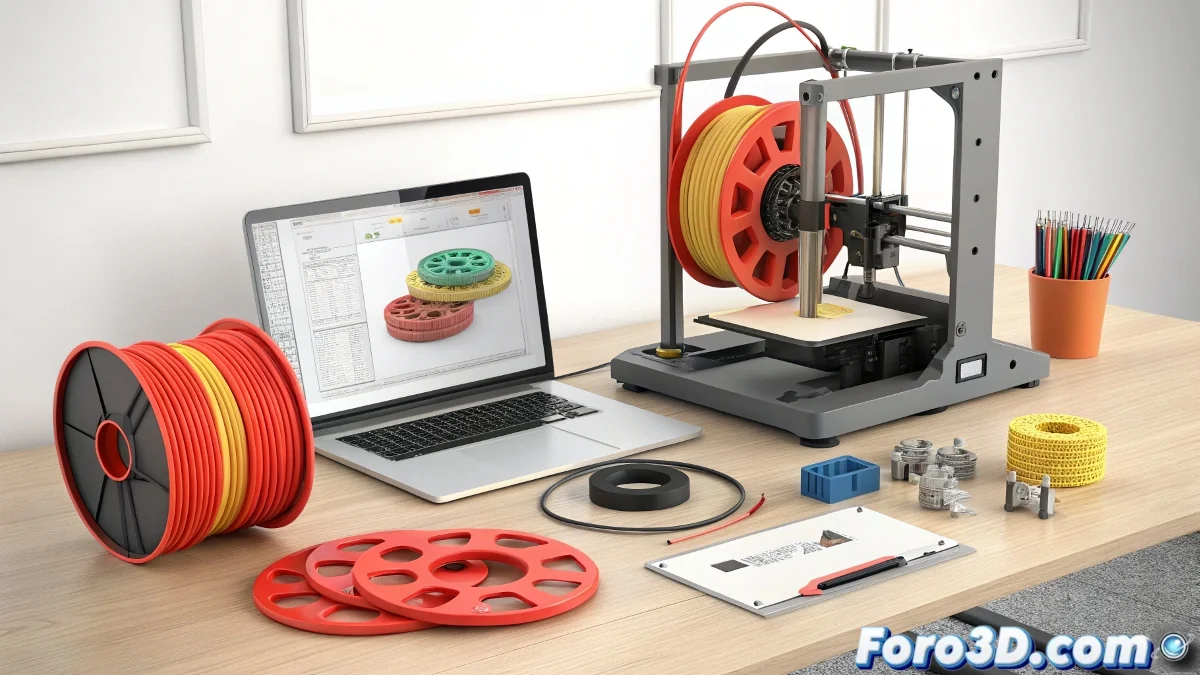

Flexible PLA offers the perfect balance between ease of use and elastic capabilities

A significant advantage of Flexible PLA is its ability to create parts that absorb impacts without being excessively soft. This makes it ideal for protectors, light shock absorbers, and components that require a certain degree of compression. Although it does not reach the extreme elasticity of TPE, its controlled flexibility is more appropriate for many practical applications where excessive deformation would be counterproductive.

Ideal Applications for Smooth Flexibility

- Protectors and bumpers for electronic devices

- Simple joints and seals requiring moderate compression

- Ergonomic components and gripping elements

- Educational toys and prototypes with flexible elements

The accessibility of Flexible PLA has democratized the creation of parts with elastic properties, allowing makers, educators, and small businesses to incorporate flexibility into their designs without the need for specialized equipment. Its consistent behavior and predictable results make it the perfect material for taking the first steps into the world of flexible printing, while its practical applications demonstrate that maximum elasticity is not always needed to effectively solve design problems. 🎈

Using Flexible PLA is like learning to ride a bike with training wheels: it gives you the confidence to explore flexibility without the fear of falling with more advanced materials, although eventually you'll want to remove the aids. 🚴

You can see this product and similar ones in the : store