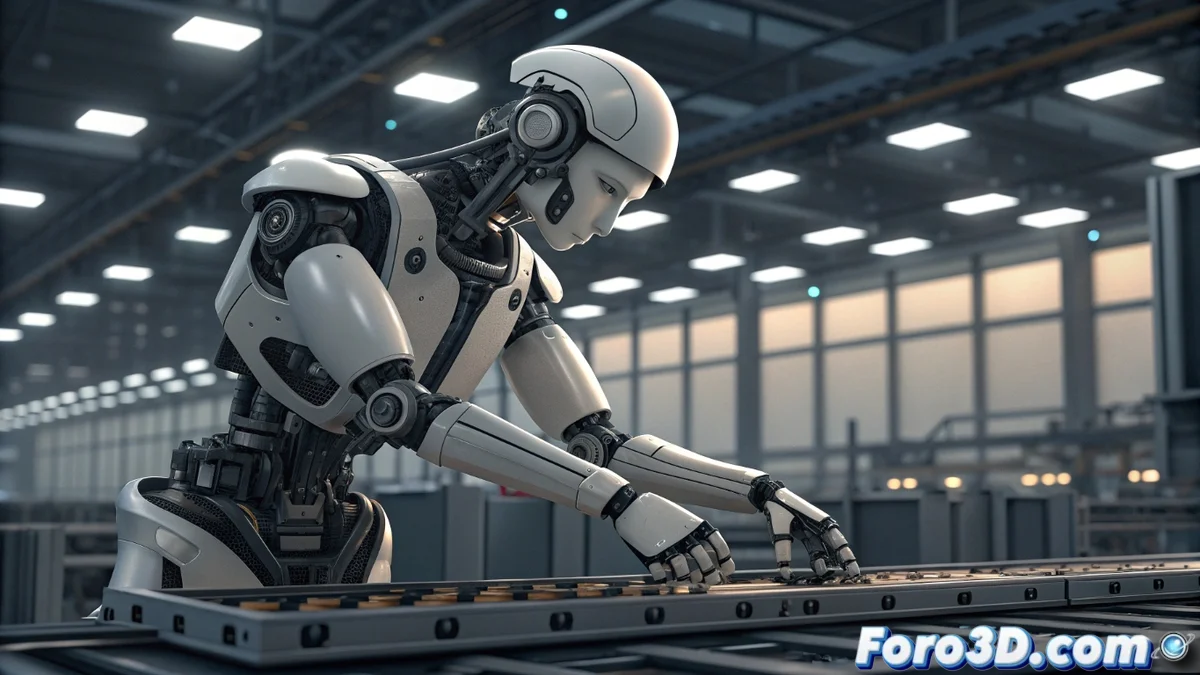

Figure 01: The Humanoid Robot Designed for Industrial Work

The company Figure AI has introduced Figure 01, a technological breakthrough that redefines the concept of humanoid robotics applied. Unlike other more conceptual projects, this automaton is born with a clear mission: to integrate practically and safely into workspaces already built for people, taking on monotonous or risky tasks. Its development marks a milestone toward intelligent automation in key sectors of the economy. 🤖

The revolution is in its hands and its learning capacity

What distinguishes Figure 01 is not only its human form, but its capabilities. Its five-fingered articulated hands offer unprecedented precision, allowing it to manipulate everything from delicate objects to power tools with fine control. This manual dexterity is enhanced by an artificial intelligence system that accelerates its training. The robot can learn new tasks by observing an operator or processing instructions in natural language, eliminating the need for complex and extensive programming for each specific function.

Key features of its learning and manipulation system:- Learning by observation: Assimilates complex procedures by watching a human demonstration, reducing implementation time.

- Natural language interaction: Responds to verbal or written commands, making communication with human supervisors more intuitive.

- Manipulation of diverse objects: Its bionic hands are designed to grasp, rotate, insert, and use a wide range of tools and industrial components.

Figure AI's philosophy is purely utilitarian. The robot is designed to be an immediate workforce solution in industrial environments.

A design focused on utility and practical mobility

Figure AI's approach is diametrically opposed to that of humanoids conceived for companionship or exhibition. Figure 01 is, above all, a worker. Its biomechanical design prioritizes stability and efficiency in real industrial environments. Its bipedal locomotion allows it to move freely through narrow aisles, climb stairs, and access workstations without requiring costly modifications to existing infrastructure. This inherently human mobility is its great advantage for logistics and warehousing.

Areas of application and strategic collaborations:- Warehouse automation: For picking, sorting, and packaging goods, alleviating labor shortages.

- Manufacturing lines: Performing assembly, inspection, and material handling tasks in potentially hazardous conditions.

- Real-world testing: Figure AI has already established agreements with major manufacturers to implement and validate the robot's capabilities in daily production operations.

The future of collaborative work

The promise of Figure 01 goes beyond simple automation; it is about synergistic collaboration between humans and machines. While operators focus on supervision, problem-solving, and creativity, humanoids take on the physical and repetitive load. Its rapid learning curve opens up an almost unlimited range of possibilities, from complex logistics tasks to, as some joke, making office coffee or picking up what has fallen. Its arrival signals the beginning of a new era in industrial applied robotics, where the human form finally translates into a tangible and productive function. ⚙️